Reinforced Cement Concrete (RCC) is the backbone of modern construction. Slabs, beams, columns, footings—almost every structural element depends on RCC. But one of the most confusing aspects for engineers and contractors is how the RCC rate is actually calculated.

Why does the RCC rate differ from site to site?

Why does one contractor quote ₹6,500/m³ while another quotes ₹8,000/m³?

The answer lies in proper rate analysis of RCC work.

This guide explains RCC rate analysis in a clear, practical, and step-by-step manner, exactly the way it is understood on real construction sites.

What Is Rate Analysis of RCC Work?

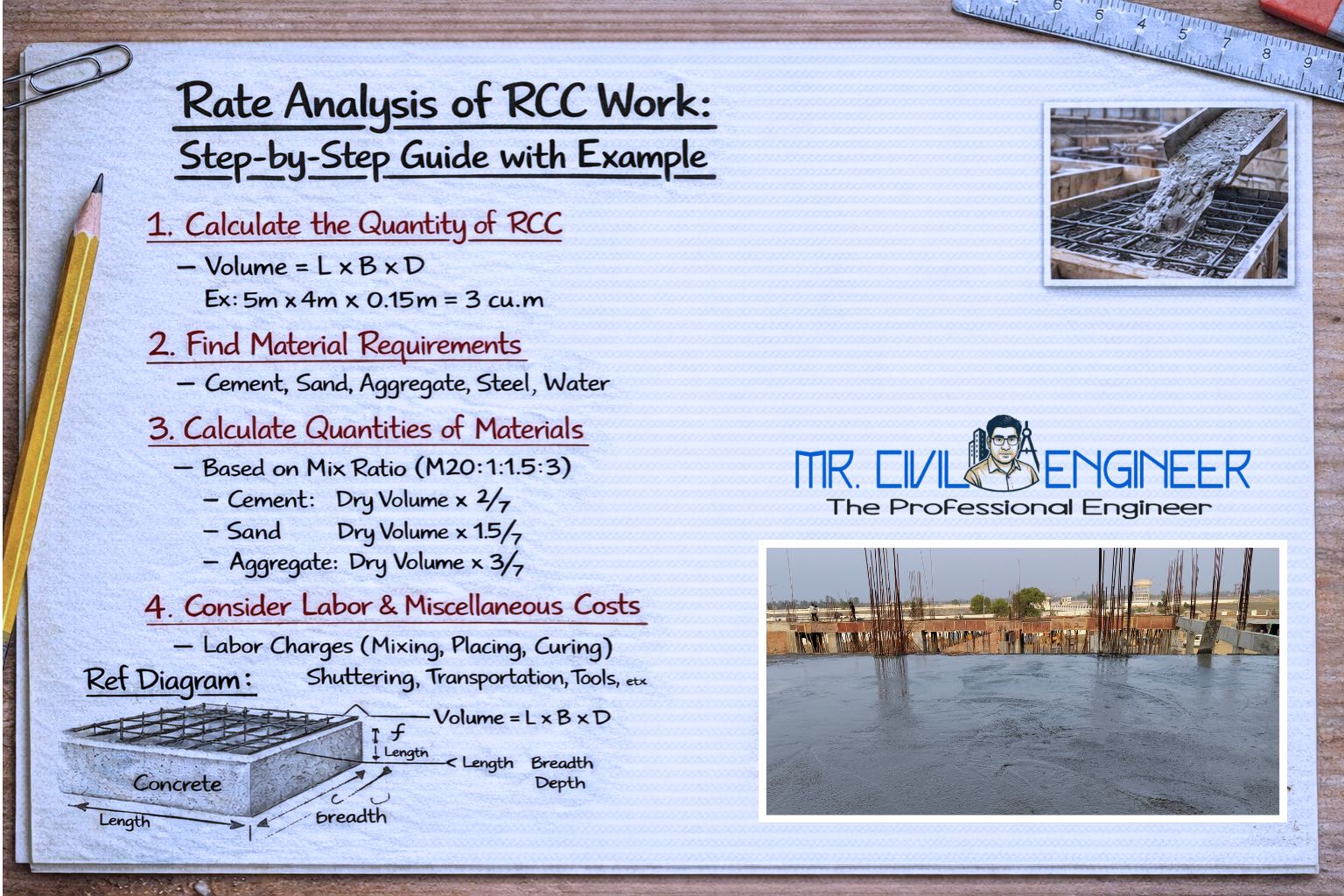

Rate analysis of RCC work is the process of determining the unit cost (per m³) of reinforced cement concrete by calculating:

- Material cost

- Labour cost

- Shuttering / formwork cost

- Equipment, overheads, and contractor profit

Estimation vs Rate Analysis

- Estimation: Calculates quantities

- Rate analysis: Calculates cost per unit

Rate analysis answers one key question:

👉 How much does 1 cubic meter of RCC actually cost?

Components of RCC Work

RCC work is not just concrete. It is a combination of four major components:

- Concrete (cement, sand, aggregate)

- Reinforcement steel

- Shuttering / formwork

- Labour and equipment

Ignoring any one of these leads to an incorrect RCC rate.

Data Required for RCC Rate Analysis

Before starting calculations, the following data is required:

- Grade of concrete (M20, M25, etc.)

- Mix ratio or design mix

- Steel percentage (typically 1–2%)

- Labour rates (local)

- Shuttering rate per m²

- Material market rates

For this example, we’ll use standard assumptions commonly used in residential buildings.

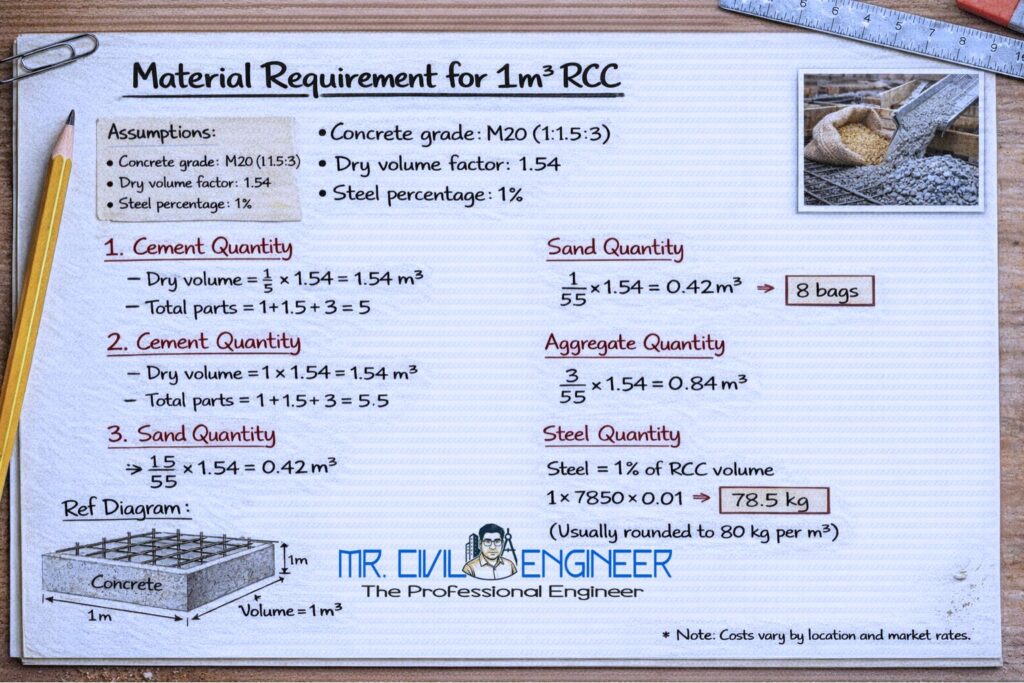

Material Requirement for 1 m³ RCC

Assumptions

- Concrete grade: M20 (1:1.5:3)

- Dry volume factor: 1.54

- Steel percentage: 1%

Cement Quantity

Dry volume = 1 × 1.54 = 1.54 m³

Total parts = 1 + 1.5 + 3 = 5.5Cement=5.51×1.54=0.28m3

Cement bags:0.28÷0.035≈8 bags

Sand Quantity

5.51.5×1.54=0.42m3

Aggregate Quantity

5.53×1.54=0.84m3

Steel Quantity

Steel = 1% of RCC volume1×7850×0.01≈78.5 kg

(Usually rounded to 80 kg per m³)

Step-by-Step Rate Analysis of RCC Work (1 m³)

Let’s assume indicative market rates (rates vary by location):

| Item | Rate |

|---|---|

| Cement | ₹400 / bag |

| Sand | ₹1,200 / m³ |

| Aggregate | ₹1,100 / m³ |

| Steel | ₹65 / kg |

| Shuttering | ₹500 / m² |

| Labour | As per standard |

1. Material Cost

Cement:

8 bags × ₹400 = ₹3,200

Sand:

0.42 m³ × ₹1,200 = ₹504

Aggregate:

0.84 m³ × ₹1,100 = ₹924

Steel:

80 kg × ₹65 = ₹5,200

Total Material Cost = ₹9,828

2. Labour Cost (Approximate)

| Labour Type | Cost (₹) |

|---|---|

| Mason & helpers | 900 |

| Bar bending | 700 |

| Mixing, placing, curing | 600 |

Total Labour Cost = ₹2,200

3. Shuttering / Formwork Cost

Average shuttering area per m³ RCC ≈ 6 m²

6 m² × ₹500 = ₹3,000

4. Equipment & Miscellaneous

- Concrete mixer, vibrator, tools

- Water, electricity, curing

Approximate = ₹400

Total RCC Rate (Before Profit)

| Component | Cost (₹) |

|---|---|

| Materials | 9,828 |

| Labour | 2,200 |

| Shuttering | 3,000 |

| Equipment | 400 |

Sub Total = ₹15,428

Contractor Profit & Overheads

Add 10–15% contractor margin.

15% of ₹15,428 ≈ ₹2,300

Final RCC Rate

RCC Rate≈₹17,500 per m3

This is a realistic site-level RCC rate for residential buildings.

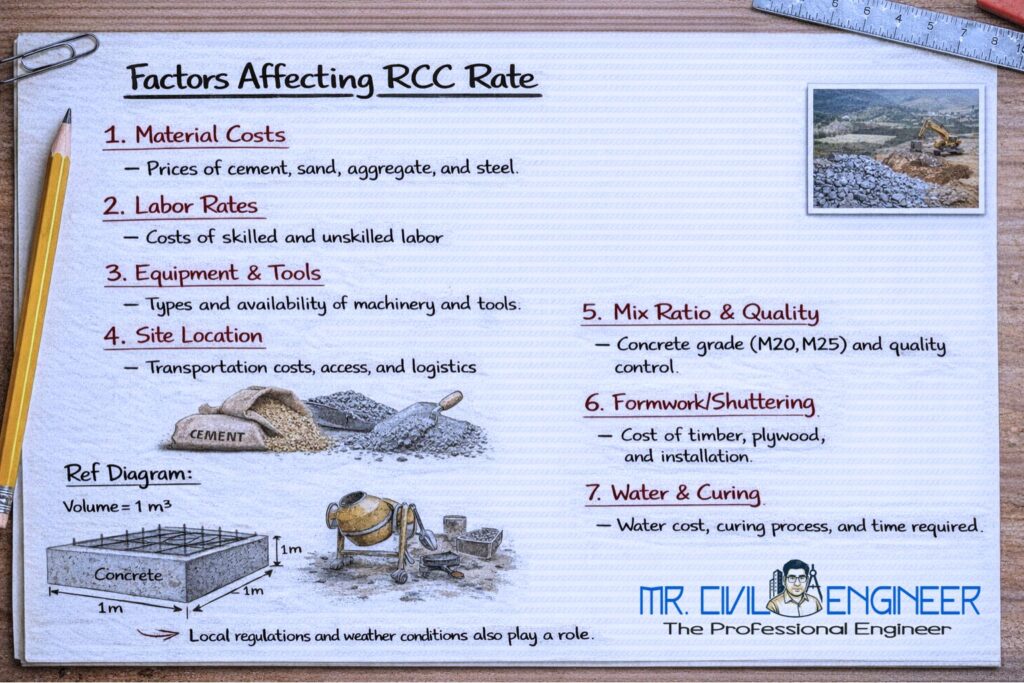

Factors Affecting RCC Rate

RCC rate is not fixed. It varies due to:

- Location and material availability

- Height of building (lifting cost)

- Congestion of reinforcement

- Type of shuttering (steel / plywood)

- Market fluctuations in steel and cement

This is why RCC rates differ from project to project.

FAQs

Q1. What is the average rate of RCC work per m³?

Usually between ₹6,500 to ₹8,000 for labour-only and ₹15,000 to ₹18,000 including material.

Q2. How much steel is required per m³ RCC?

Typically 80–120 kg, depending on structural design.

Q3. Is shuttering included in RCC rate?

Yes, in complete RCC rate analysis.

Q4. Does RCC rate change for slabs, beams, and columns?

Yes. Columns usually cost more due to higher shuttering and steel congestion.

Conclusion

The rate analysis of RCC work is not just a textbook exercise—it is a practical financial tool. It helps engineers prepare accurate estimates, contractors quote realistic prices, and clients understand where their money is going.

By breaking RCC into materials, labour, shuttering, and overheads, you gain full cost transparency and avoid disputes, underquoting, or losses.

In construction, strong structures begin with strong calculations.

Latest Articles

- Plaster Quantity Calculation (Area-Wise): Step-by-Step Guide

- Brickwork Quantity Calculation (With Formula): Step-by-Step Guide

- Cement, Sand & Aggregate Calculation for House: Step-by-Step Guide

- Building Estimation & Costing: A Complete Guide for Accurate Construction Planning

- RCC Work Checklist for Site Engineers 2026