If the cement going into a house is fake or low quality, the structure can start cracking or leaking long before its time. Many homeowners only realize the damage when plaster falls off, damp patches appear, or slabs develop scary cracks, by which time repairs are expensive and stressful. The good news is that with a few simple checks, anyone can learn how to identify original vs duplicate cement in just a few minutes on site.

This guide walks through clear steps you can follow at the time of purchase and during material delivery so that poor or duplicate cement never enters your project. Whether you are a first‑time home builder or a junior site engineer, the aim is to give practical, field‑friendly checks—not complicated lab procedures.

Why checking cement authenticity matters

Cement is the binding material that holds together sand, aggregates, and bricks; if this “glue” is weak, the entire structure suffers. Fake or substandard cement leads to low compressive strength, higher shrinkage, more cracks, and long‑term durability issues such as dampness and spalling. In many regions, enforcement is improving but cases of duplicate cement units being busted still appear in news and educational videos. Spending even 10–15 minutes checking each truck or batch is a small investment compared to the cost of structural repairs or safety risks later.

Original vs duplicate vs expired cement

Before jumping into tests, it helps to understand three different issues: authenticity, duplication, and age.

- Original cement: Manufactured by a licensed brand, packed in genuine bags, and conforming to relevant standards or IS codes, usually supported by test certificates.

- Duplicate cement: Material sold in look‑alike bags that copy famous brands or filled by unauthorised units, often containing soil, stone dust, or low‑grade mixes instead of proper cement.

- Expired or poorly stored cement: Genuine cement that has crossed a reasonable storage period (often beyond around three months from manufacture) or has absorbed moisture, forming hard lumps and losing strength.

Your goal on site is to screen for all three: reject anything that looks duplicated, very old, or badly stored—even if the logo on the bag appears familiar.

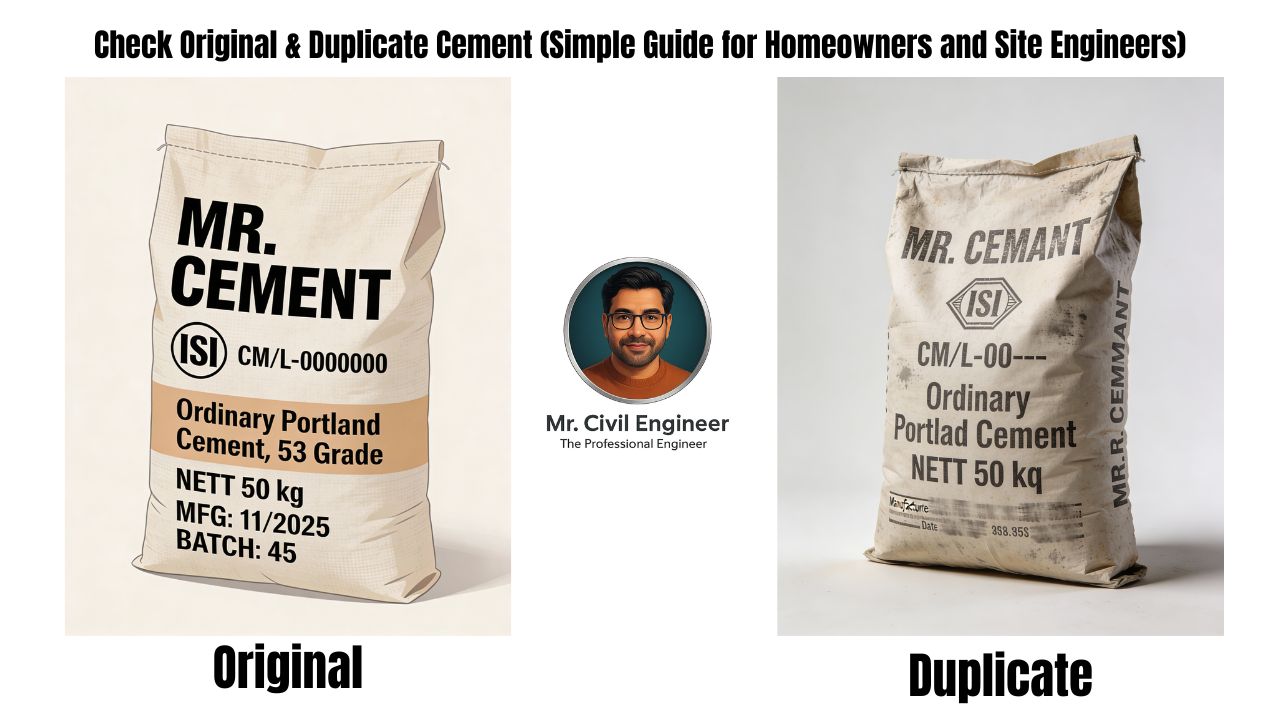

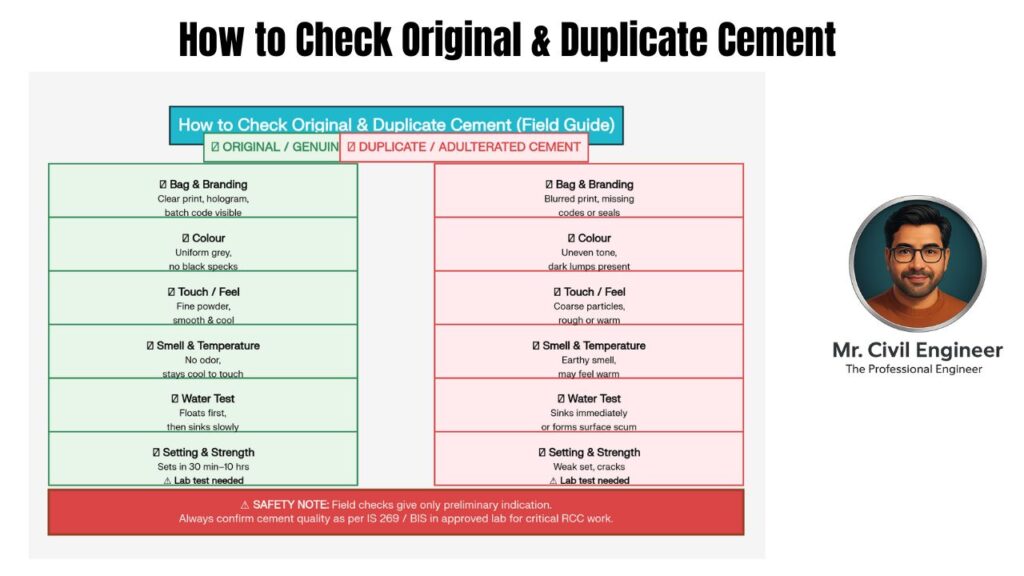

First line of defence: checking the cement bag

Most duplicate cement can be caught before even opening the bag if you know what to look for.

1. Check brand name, logo, and printing quality

Start by carefully reading the manufacturer’s name and registered trademark. Genuine bags have crisp printing, correct spelling, and consistent fonts and logo shapes. Duplicate bags often reveal themselves through:

- Slight spelling mistakes in brand name.

- Poor printing quality (blurred, smudged, off‑colour logos).

- Logos that look similar but not identical to the original design.

When in doubt, compare the bag with a sample image from the brand’s official website or brochure.

2. Confirm standard mark and grade

In India, a genuine bag should carry the ISI mark printed correctly, often in black, indicating that the cement meets BIS specifications. The bag must also clearly mention:

- Type of cement (OPC, PPC, PSC, etc.).

- Grade (e.g., 33, 43, 53 for OPC).

If the standard mark is missing, badly printed, or looks altered, treat it as a major warning sign.

3. Read manufacturing date, batch number, and plant details

Manufacturing date and batch number are crucial for judging freshness and traceability. They are usually printed near the stitching or one side of the bag, sometimes coded by month and year. As a practical rule, try to use cement within about 90 days from the date of manufacture for most small projects, particularly in hot and humid climates.

Also, check that the plant address and other contact details look complete and authentic. Suspicious or missing factory details can indicate counterfeit packing.

4. Verify bag weight, seal, and physical condition

Standard cement bags are 50 kg; if a bag feels unusually light, check at least one on a weighing scale. The bag should be properly sealed, with no signs of re‑stitching, tears, or excessive powder leakage. Visible moisture marks, caking, or damp patches on the outside suggest that the cement inside may already be compromised.

Simple field tests to check cement quality

Once the bags pass visual checks, you can perform a few basic field tests using a small sample. These do not replace lab tests but are effective screening tools at site level.

1. Color test

Take cement from a freshly opened bag and spread it on a white surface. Good quality cement generally has a uniform grey shade, often with a slight greenish or bluish tint depending on the type and brand. If you see very light, brownish, or highly non‑uniform color—with darker and lighter streaks—it may indicate impurities, adulteration, or mixing with foreign materials.

2. Touch / smoothness test

Rub a pinch of cement between your thumb and fingers. Original, well‑ground cement feels smooth and fine, similar to soft powder, and you should not feel coarse sand‑like grains. Fake or low‑grade cement often feels gritty or rough due to improper grinding or addition of fine sand or filler.

3. Lumps and tap test

Gently press or knead the cement inside the bag, or open one and break apart any lumps you find. A few soft lumps that crumble easily under pressure are normal and may just indicate slight moisture exposure. However, if you find large, hard lumps that do not break easily, the cement has absorbed significant moisture and has likely lost strength; such bags should be rejected.

4. Float / water test

Take a handful of cement and sprinkle it gently on the surface of a bucket of clean water without stirring. Good quality cement tends to float initially and then slowly sinks as hydration starts and particles get wet. If the cement sinks immediately in a lump or disperses in an irregular way, it may indicate poor fineness or improper composition.

5. Quick paste / adhesion test

Mix a small quantity of cement with water to form a paste and smear it on a smooth, non‑absorbent surface like a tile or glass piece. Original cement forms a uniform, sticky paste that adheres well and does not segregate quickly. Counterfeit or weak cement often releases water quickly, shows an uneven texture, or feels crumbly and non‑adhesive. Leaving this sample undisturbed for 24 hours can give a rough idea of its setting and early hardness.

6. Temperature and smell check

Take some cement in your hand; it should feel cool to touch, indicating it has been stored properly and is not reacting prematurely. If the cement feels warm, has a musty odour, or smells unusual, it could be due to moisture or contaminants and should be treated with caution.

How much time should you spend on these checks?

For a typical small delivery, a simple routine can take about 10–15 minutes and save you from major problems.

- 3–5 minutes: Inspect printing, ISI mark, brand name, manufacturing date, and bag condition on at least 3–4 randomly selected bags.

- 5–10 minutes: Perform color, touch, lump, and float or paste tests using a small sample from one or two bags.

For large projects or when any doubt remains, follow up with formal lab testing as per relevant standards before structural concreting.

Common red flags that signal duplicate or risky cement

Some warning signs should immediately make you pause and re‑check:

- Brand name spelling or logo design that looks slightly “off”.

- Absence of ISI/standard mark, grade, or type marking on the bag.

- Missing or unreadable manufacturing date and batch number.

- Unusually low price compared to prevailing local rates or insistence on cash without proper invoice.

- Very non‑uniform color, distinctly gritty feel, lots of hard lumps, or failed float/paste tests.

If you observe more than one of these together, it is safer to reject the consignment rather than “adjust” for cost.

What to do if you suspect fake or low‑quality cement

- First, stop using the suspect bags and clearly mark or isolate them on site.

- Inform the supplier immediately with photos and details of the issues.

- Ask for replacement from a trusted brand or a refund; do not proceed with critical works using doubtful material.

- For repeated or large‑scale concerns, lodge a complaint with the manufacturer’s customer care or appropriate standards authority, sharing bag photos, batch numbers, and invoices.

- When structural safety is involved, consider sending a sample to a recognized lab for compressive strength and standard code tests.

Prevention tips: how to avoid duplicate cement in the first place

Avoiding fake cement is easier than dealing with the consequences later.

- Purchase from authorized dealers and reputed local suppliers instead of unknown mobile vendors.

- Prefer established brands with strong quality control rather than unbranded or very new names offered at steep discounts.

- Always demand a proper invoice with brand name, cement type, and batch details.

- Cross‑check packaging design once from the brand’s official website or brochure before placing large orders.

- Use cement as early as practical and avoid long on‑site storage, especially in damp seasons.

FAQs

1. How many months after manufacturing is cement safe to use?

Practically, many experts recommend using bagged cement within around 90 days of manufacture for best results, especially in humid climates. Strength can gradually reduce with longer storage, even if the bag remains sealed.

2. Is lumpy cement always bad?

Small soft lumps that break easily between fingers usually indicate minor moisture exposure and can sometimes be acceptable. Hard, stone‑like lumps that do not crumble are a strong sign of deterioration and such bags should be rejected.

3. Can field tests fully replace lab tests?

No. Field tests like color, touch, float, and paste checks are quick screening tools that help you decide whether to accept or reject material on site. For final confirmation of compressive strength and standard compliance, laboratory tests as per codes are required.

4. Is cheaper cement always duplicate?

Not always, as prices can vary with brand, region, and bulk deals, but if the rate is significantly below market and other red flags are present, be extra cautious.

5. Do OPC and PPC require different checks for originality?

The basic authenticity checks—bag printing, ISI/standard mark, manufacturing date, and field tests—remain the same for OPC and PPC. Just make sure the type and grade printed on the bag match what your design or engineer specifies.

Conclusion

Checking whether cement is original or duplicate is not a complicated lab exercise; it is mostly about being observant and consistent with a simple on‑site checklist. By verifying the bag, running a few quick field tests, and buying only from trusted sources, homeowners and engineers can greatly reduce the risk of fake or low‑quality cement entering their projects. With just a few extra minutes per delivery, you protect the strength, safety, and lifespan of the structure you are building.

Read This Also

- Types of Soil Tests for Building Construction

- Latest Building Materials in Construction (2026 Update)

- How to Estimate Brickwork and Rate Analysis with Example

- Application of Smart Materials in Structural Engineering

- Top 20 Latest Advancements in Concrete Technology (2025–2026)

- Types of Staircases – Complete Classification, Features, and Uses