Concrete is often thought of as a single, solid mass—but in real construction, continuous concrete pouring is rarely possible. Due to time limits, manpower constraints, and equipment availability, concrete work is usually done in stages. This is where construction joints come into play.

When planned properly, construction joints are safe and functional. When ignored or wrongly located, they become weak points, leading to cracks, leakage, and durability problems.

This guide explains construction joints – types & location in a clear, site-practical manner.

What Are Construction Joints?

A construction joint is the interface between two successive concrete pours when concreting is stopped and resumed later.

In simple words:

Wherever today’s concrete meets tomorrow’s concrete, a construction joint is formed.

These joints are not cracks—they are intentional and planned.

Why Construction Joints Are Necessary

Construction joints are unavoidable because:

- Concrete supply may stop

- Large pours cannot be completed in one go

- Workday time limits

- Equipment or manpower constraints

Instead of random stopping, planned construction joints ensure:

- Structural continuity

- Load transfer

- Controlled behavior of concrete

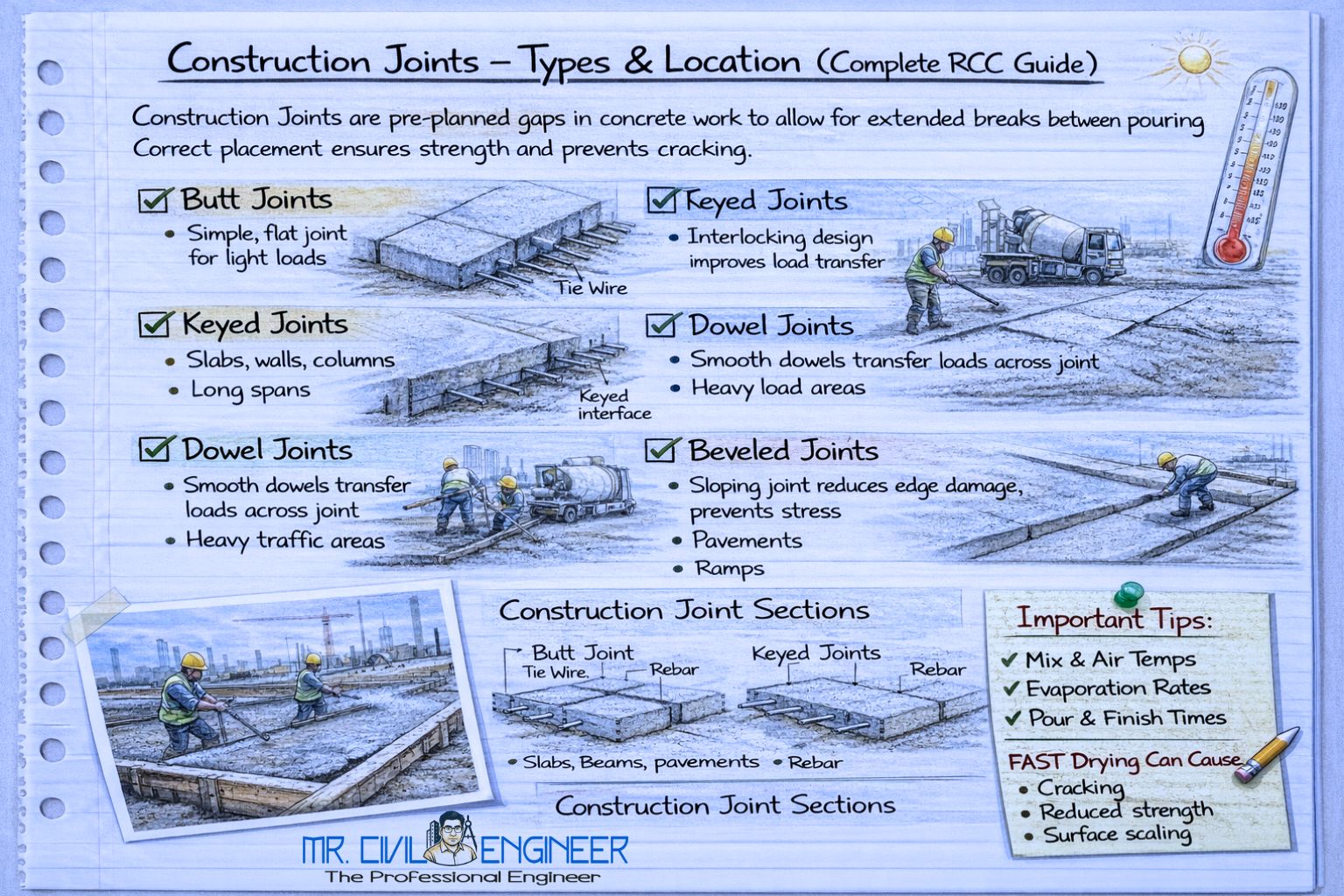

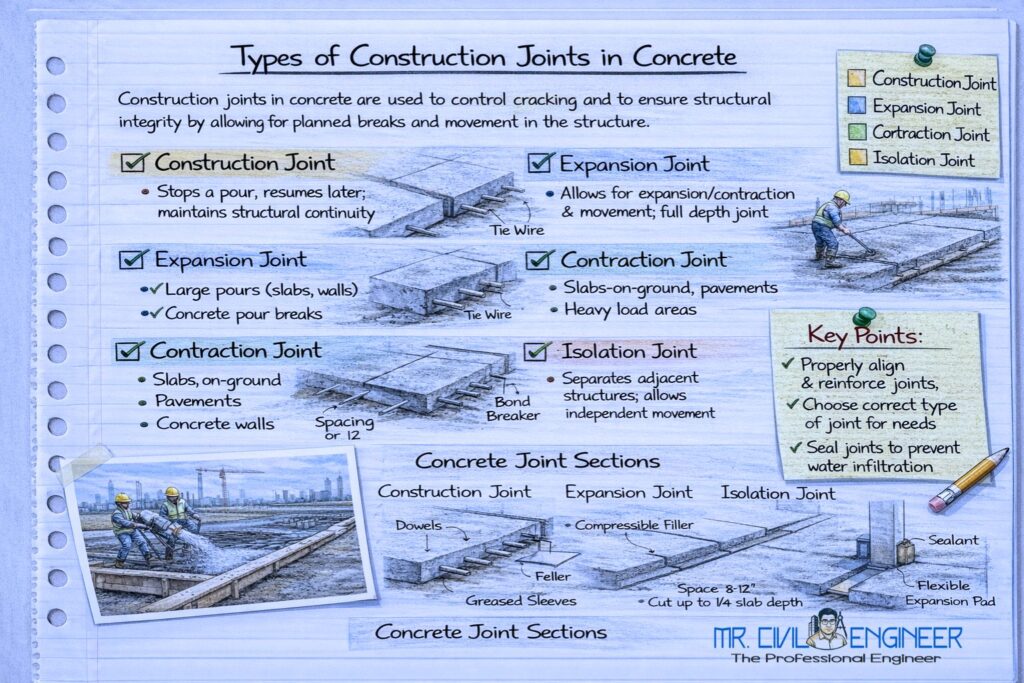

Types of Construction Joints in Concrete

Many site engineers confuse different joint types. Let’s simplify them.

1. Construction Joints

These joints are formed due to interruption in concreting.

Key Characteristics:

- Planned in advance

- Roughened surface before next pour

- Bonding ensured using cement slurry

Common Locations:

- Slabs

- Beams

- Columns

- Walls

2. Expansion Joints

Expansion joints allow concrete to expand and contract due to temperature changes.

Purpose:

- Prevent thermal cracks

- Allow movement

Common Locations:

- Long buildings

- Bridges

- Pavements

Filled With:

Bitumen, rubber pads, or compressible material.

3. Contraction (Control) Joints

Concrete shrinks while drying. Control joints control shrinkage cracks.

Purpose:

- Create a predefined weak line

- Prevent random cracking

Common Locations:

- Slabs on grade

- Pavements

- Floors

4. Isolation Joints

Isolation joints separate one structural element from another.

Purpose:

- Prevent load transfer

- Avoid stress due to differential movement

Common Locations:

- Column–slab junction

- Staircase and building

- Machine foundations

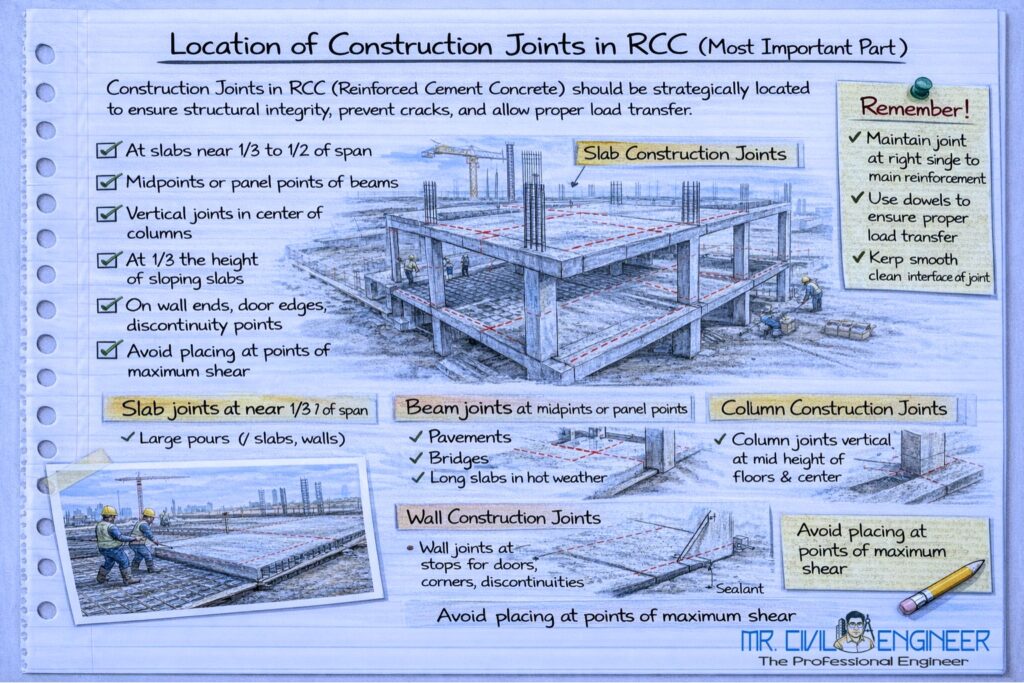

Location of Construction Joints in RCC (Most Important Part)

Correct joint location is more important than joint type.

Construction Joint Location in Slabs

✔ Preferred Location:

- At 1/3rd span from support

- Parallel to shorter span

🚫 Avoid:

- Mid-span (maximum bending moment zone)

📌 Rule: Always place joints where shear force is minimum.

Construction Joint Location in Beams

✔ Preferred Location:

- Near support, not at mid-span

- At beam–column junction with proper detailing

🚫 Avoid:

- Center of beam (high bending stress zone)

Construction Joint Location in Columns

✔ Best Location:

- At floor level

- Just above slab level

🚫 Avoid:

- Mid-height of column

📌 Column joints must ensure vertical load continuity.

Construction Joint Location in Walls

✔ Preferred Location:

- At horizontal levels

- Where bending stress is low

🚫 Avoid:

- Random vertical joints without detailing

Construction Joint Location in Footings

✔ Best Practice:

- Avoid joints in footings if possible

- If unavoidable, place joint above footing top

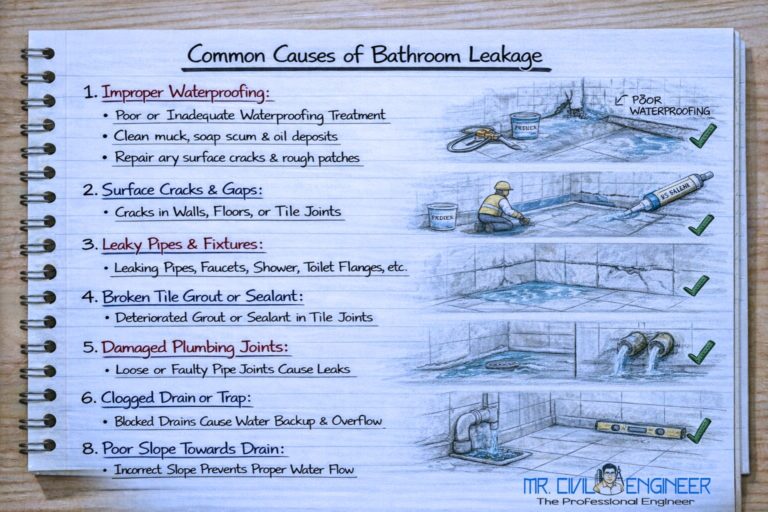

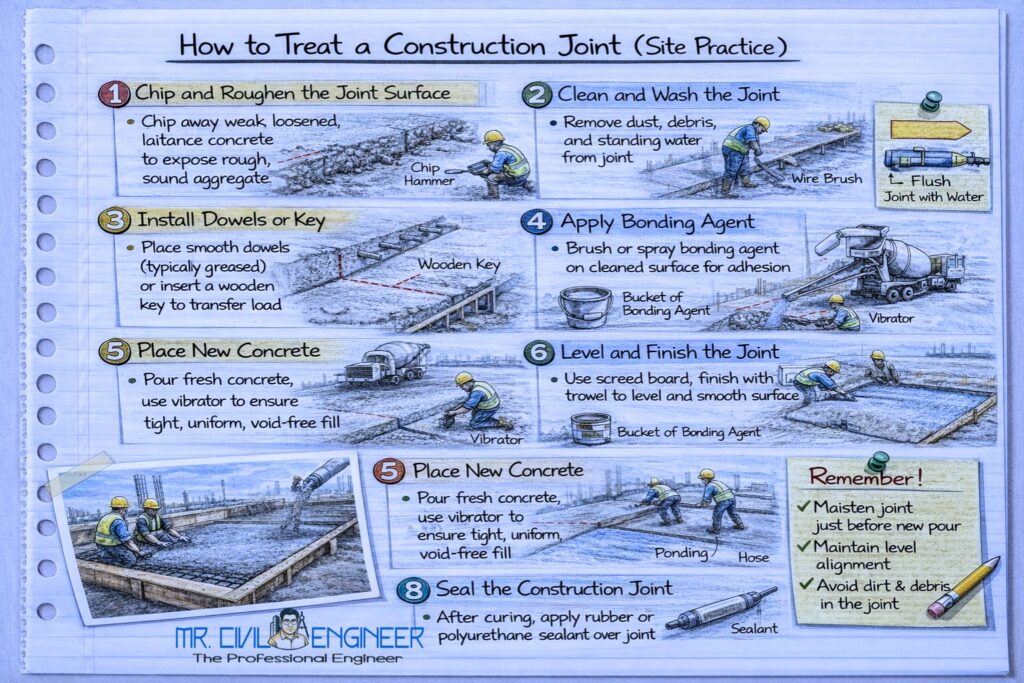

How to Treat a Construction Joint (Site Practice)

Proper treatment ensures strength continuity.

Steps:

- Roughen old concrete surface

- Clean dust and loose particles

- Apply cement slurry or bonding agent

- Place new concrete with proper vibration

📌 Neglecting joint treatment leads to cold joints and leakage.

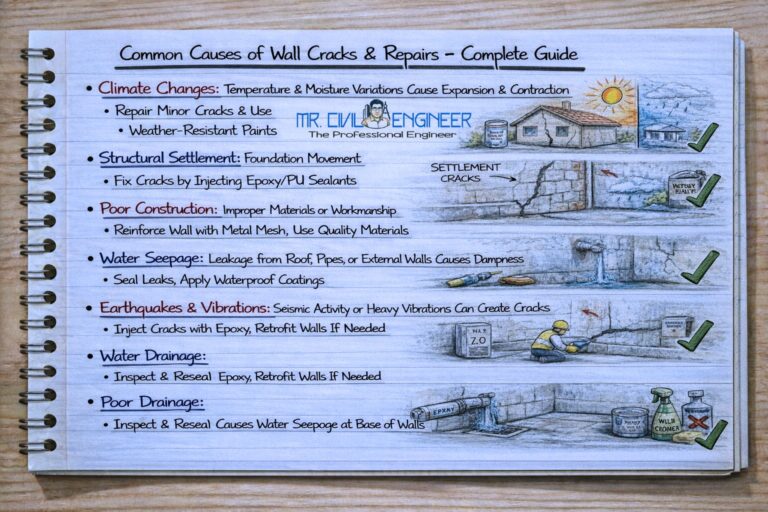

Common Mistakes Related to Construction Joints

- Providing joints at high stress zones

- Poor surface preparation

- No bonding slurry

- Random stopping of concrete

- Confusing construction joints with expansion joints

These mistakes are major reasons for leakage in slabs and walls.

Frequently Asked Questions (FAQs)

Q1. Are construction joints weak points?

No, if properly planned and treated.

Q2. Can construction joints be avoided completely?

Practically no, but they can be minimized.

Q3. What happens if joints are wrongly located?

Cracks, leakage, and reduced durability occur.

Conclusion

Construction joints are not defects—they are engineering decisions. The key lies in correct type selection, proper location, and proper treatment.

In RCC construction:

Well-planned joints protect structures. Poorly planned joints destroy them.

Understanding construction joints – types & location is a must for every civil engineer and site professional.