Imagine stepping onto your first construction site as a fresh civil engineering graduate, only to freeze when the supervisor asks, “Check if this column is plumb and the concrete slump is right.” Heart racing, you nod while secretly wishing college had taught the real basics. If that sounds familiar, you’re in good company—most beginners struggle with bridging theory and practice. This guide covers 12 civil engineering basics every beginner must know, explained simply with site-ready tips to build your confidence fast.

1. Loads and Forces: What Keeps Structures Standing

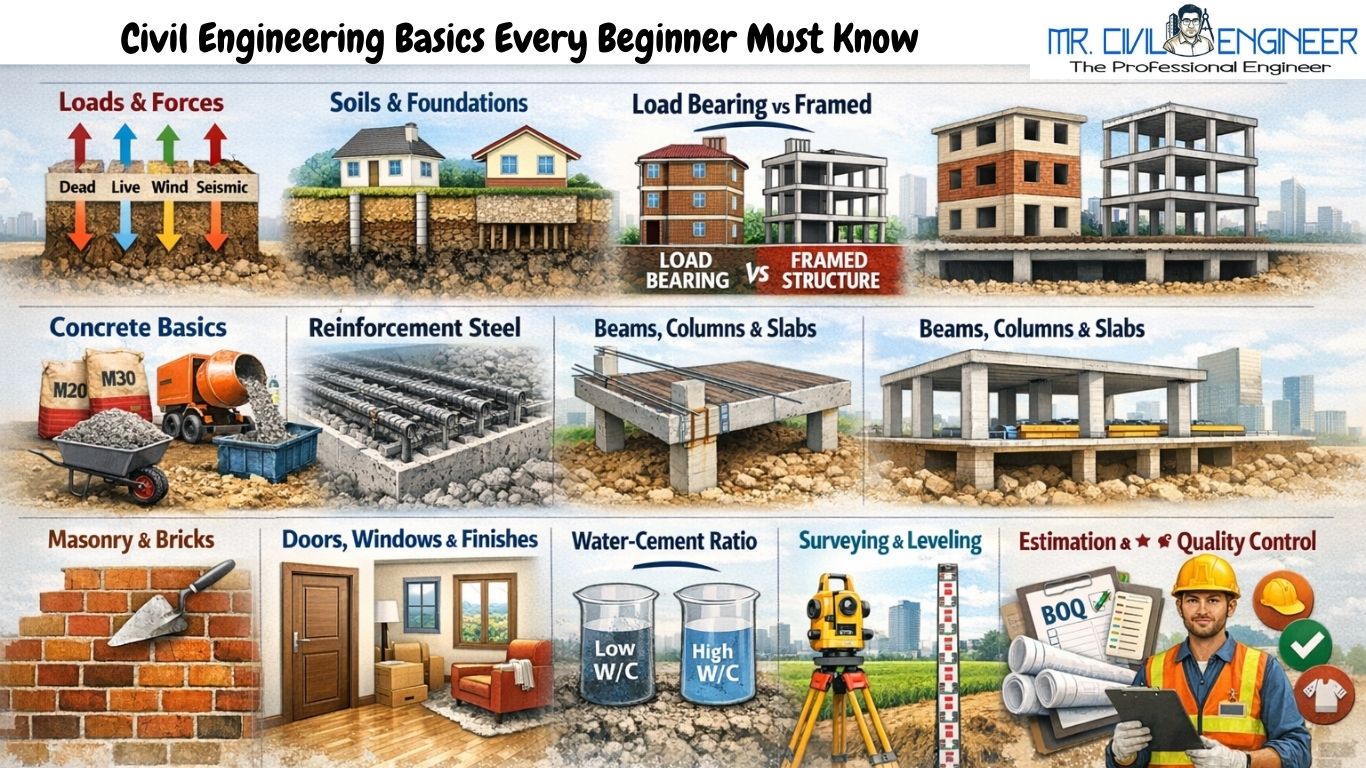

Every structure fights gravity and nature daily. Dead loads are permanent weights like the building’s own concrete and bricks—think of them as the structure’s “body weight.” Live loads are changing, like people, furniture, or vehicles (typically 2–5 kN/m² for residential floors).

Wind and earthquakes add lateral forces, so designs include safety factors (1.5 for DL+LL, higher for seismic zones). Loads transfer from slabs to beams, beams to columns, columns to footings, and footings to soil—like a relay race where each member passes the “baton” safely. Understanding load paths prevents collapses; always sketch them for exams.

2. Soils and Foundations: Build on Solid Ground

Soil isn’t just dirt—it’s your structure’s ultimate support. Bearing capacity measures how much load soil can take before failing (safe values: 100–300 kN/m² for sand, less for clay). Test it with plate load or SPT for big projects.

Shallow foundations (footings, raft) suit firm soil; deep foundations (piles, caissons) for weak or waterlogged ground. Rule of thumb: isolated footing size = √(load / bearing capacity). For a 100-ton column on 150 kN/m² soil, footing ≈ 3m x 3m. Always provide 50mm DPC at plinth to stop rising damp.

3. Structural Systems: Load Bearing vs Framed

Load bearing walls carry loads directly to foundations—simple, cheap for 1–2 storeys using thick brick walls (230mm). But multi-storey? Switch to RCC framed structure: columns/beams take loads, thin infill walls (115mm) just partition.

Framed is king in India (90% urban homes) for open plans and earthquakes. Analogy: load bearing is like a stack of books; framed is a bookshelf frame holding shelves.

| Aspect | Load Bearing | Framed Structure |

|---|---|---|

| Storeys | G+1 max | G+10 |

| Cost | Lower initial | Higher but versatile |

| Speed | Slower | Faster (parallel work) |

| Flexibility | Low (fixed walls) | High (open plans) |

4. Concrete Basics: Grades, Mixes, and Curing

Concrete = cement + sand + aggregate + water. Grades like M20 (20 MPa strength at 28 days) mean house slabs/ beams; M25+ for columns/footings. Mix ratio for M20: 1:1.5:3 (cement:sand:20mm aggregate) by volume.

Water-cement ratio (0.45–0.5) is critical—too much weakens it (like overwatering plants). Slump test (75–100mm for beams) checks workability. Cure wet for 7–14 days (jute bags, ponding) to gain 90% strength. Cube test: crush at 7/28 days for quality proof.

5. Reinforcement Steel: Hidden Strength

Steel bars (rebars) take tension where concrete cracks. Grades: Fe415 (yield 415 MPa) for homes; Fe500 for seismic zones (stronger, less lap). Diameter: 8–32mm (10/12mm stirrups, 16–25mm main bars).

Lap length: 40–50x bar dia (e.g., 500mm for 12mm). Development length anchors bars into concrete. BBS (bar bending schedule) lists cuts/bends—master it for estimation jobs. Analogy: rebar is bones in concrete’s flesh.

6. Beams, Columns, Slabs: The Building Skeleton

- Slab: Flat/ribbed, spans 3–5m, thickness = span/30 (125mm for 4m). One-way (short span loaded), two-way (square).

- Beam: Horizontal, depth = span/12–15 (250mm for 3.5m). Takes slab loads to columns.

- Column: Vertical, min 230x230mm, tied with stirrups @150mm c/c.

Load path: slab → beam → column → footing. Check cover (40mm slabs, 50mm footings) against corrosion.

7. Masonry and Bricks: Strong Walls

Bricks: First class (190kg/cm² strength) for load bearing. Types: clay (traditional), fly ash (eco), AAC blocks (light, insulating, 3–6″ thick).

Mortar: 1:6 cement-sand for walls. English bond for strength. Plumb walls daily; cure 7 days. Thickness: 115mm partition, 230mm load bearing.

8. Doors, Windows, Finishes: Practical Completion

- Doors: Panel (23mm solid), flush (35mm), frames 100x50mm teak.

- Windows: Aluminium/UPVC (powder coated), MS grills.

- Finishes: Plaster 12–20mm, vitrified tiles (600x600mm), acrylic paint.

Fix hardware post-plaster; align sills at 750–900mm.

9. Water-Cement Ratio and Workability

W/C >0.5 = porous, weak concrete. Admixtures (plasticizers) reduce water 10–20% without slump loss. Site tip: thumb test—concrete shouldn’t stick excessively.

10. Basic Surveying and Leveling

Chain surveying: 20/30m chains for small plots. Leveling: dumpy/total station for benchmarks (RL). Chainage marks station points. Rise/fall method for heights.

11. Estimation and BOQ Basics

BOQ (Bill of Quantities): lists items (100m³ concrete M20 @ ₹6000/m³). Abstract: total cost. Rates from CPWD schedule +10–20% profit.

12. Safety and Quality Control

PPE: helmet, boots, gloves. Checklists: alignment, cover, compaction. IS codes (456 concrete, 800 steel) guide all.

Common Beginner Mistakes to Avoid

- Ignoring cover → corrosion.

- Wrong laps → bond failure.

- Dry concrete → cracks.

- No curing → 50% strength loss.

FAQs Civil Engineering Basics Every Beginner Must Know

M20 vs M25 concrete?

M20 for slabs/beams (20MPa); M25 stronger for columns/footings.

Fe415 vs Fe500 steel?

Fe500 ductile for quakes; Fe415 standard homes.

Footing size basics?

Area = total load / safe bearing capacity.

Conclusion: Master Basics, Master Civil Engineering

These civil engineering basics give you a rock-solid start—whether acing exams, landing jobs, or supervising your home build. Practice sketching details, visit sites, and refer IS codes daily. You’ve got the foundation; now build tall.

Latest Posts

- House Construction Tips in India 2026: A Practical Guide for First-Time Home Builders

- Best Sustainable Construction Materials for 2026: Build Greener, Smarter, and Future‑Ready

- Green Infrastructure Design Tips: Practical Ideas for Cooler, Flood‑Safe Cities

- Robot-Assisted Construction Techniques: Faster, Safer Sites in 2026

- Civil Engineering Trends in Smart Cities: India 2026 Guide