One of the most common problems during house construction is material mismatch—either cement runs out in the middle of work or sand and aggregate are overstocked and wasted. Both situations increase cost and delay the project.

This happens because many people start construction without proper cement, sand, and aggregate calculation. If you understand the basics and follow a simple method, material estimation becomes easy and reliable.

This guide explains cement, sand & aggregate calculation for house construction in a clear, practical, and site-friendly way.

Basics of Cement, Sand & Aggregate in House Construction

Before calculation, it’s important to know why these materials matter.

- Cement: Acts as a binding material

- Sand (Fine Aggregate): Fills voids and improves workability

- Aggregate (Coarse Aggregate): Provides strength and bulk

These materials are used in:

- Footings and foundations

- Columns, beams, and slabs

- Plastering and masonry

- Flooring and PCC

Wrong quantity directly affects strength, cost, and quality.

Understanding Concrete Mix Ratios

Concrete mix ratio defines the proportion of materials.

Example:

M20 = 1 : 1.5 : 3

(Cement : Sand : Aggregate)

Common Mix Ratios Used in Houses

| Grade | Mix Ratio | Typical Use |

|---|---|---|

| M10 | 1:3:6 | PCC, leveling |

| M15 | 1:2:4 | Footpaths |

| M20 | 1:1.5:3 | RCC slabs, beams |

| M25 | Design mix | Heavy RCC |

The richer the mix, the more cement is required.

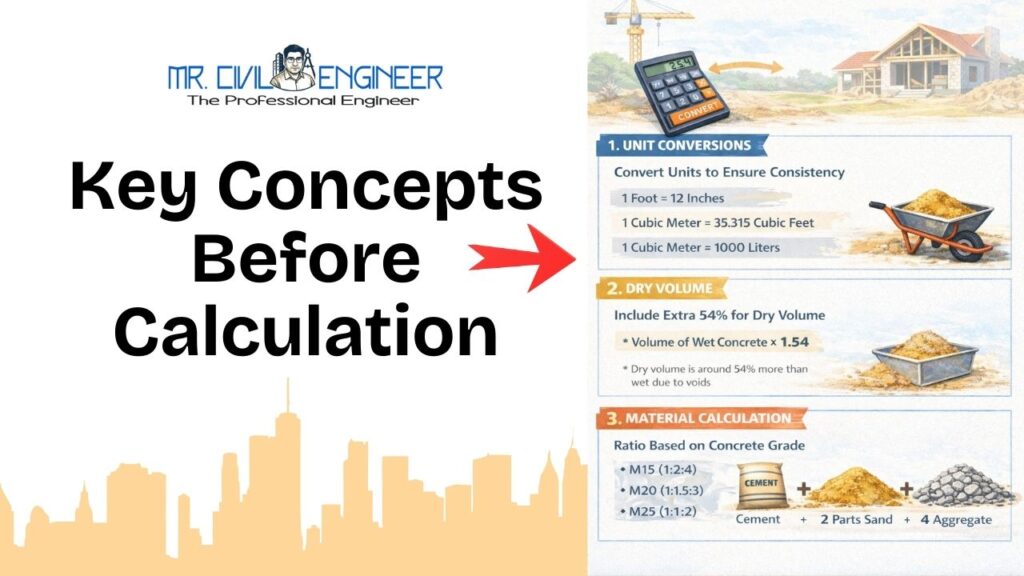

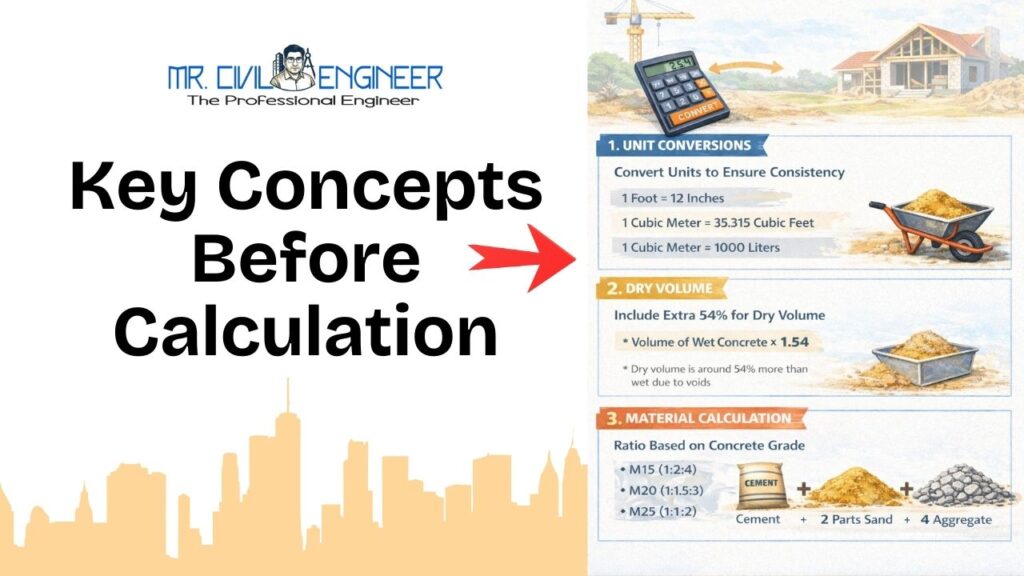

Key Concepts Before Calculation

1. Wet Volume vs Dry Volume

Concrete volume measured on drawings is wet volume.

But materials are calculated in dry state, so we convert:

Dry Volume = Wet Volume × 1.54

This factor accounts for:

- Shrinkage

- Wastage

- Air gaps

2. Cement Bag Volume

- 1 bag of cement = 50 kg

- Volume of 1 bag ≈ 0.035 m³

This helps convert cement volume into number of bags.

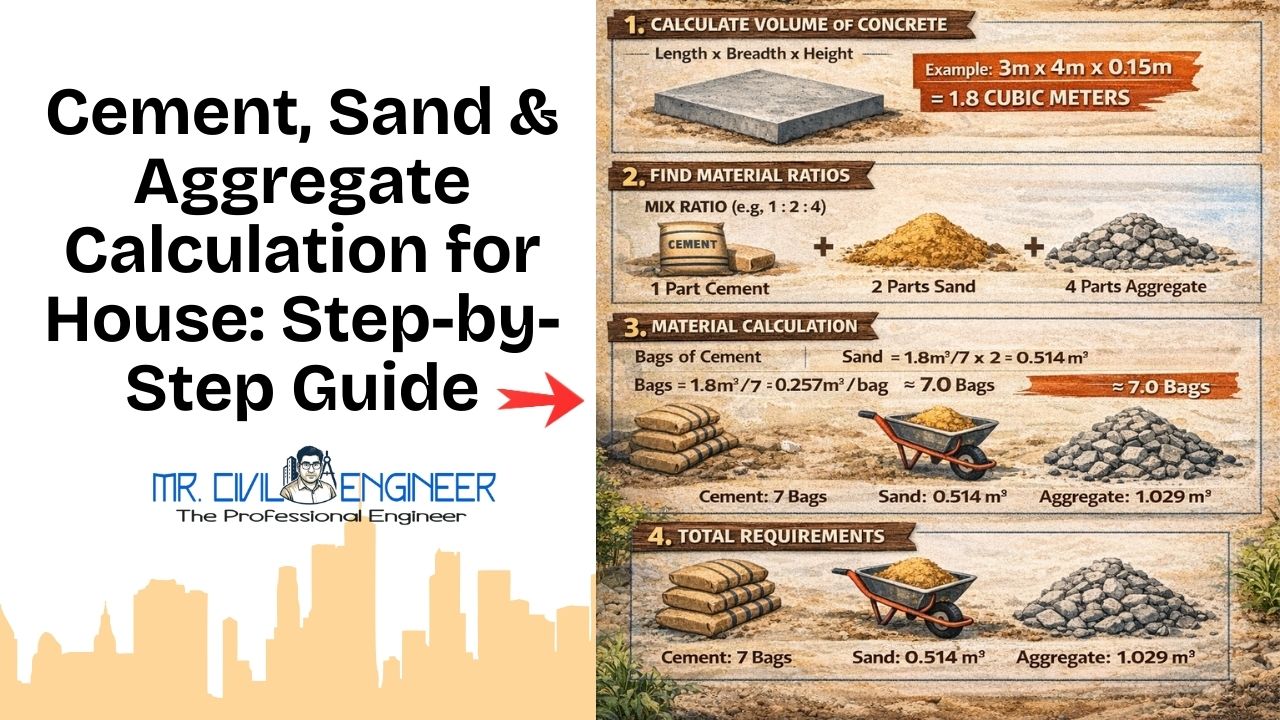

Step-by-Step Cement, Sand & Aggregate Calculation

Let’s calculate materials for 1 cubic meter of concrete.

Step 1: Calculate Dry Volume

Wet volume = 1 m³

Dry volume = 1 × 1.54 = 1.54 m³

Step 2: Select Mix Ratio (Example: M20)

M20 mix = 1 : 1.5 : 3

Total parts = 1 + 1.5 + 3 = 5.5

Step 3: Calculate Cement Quantity

Cement = (1 / 5.5) × 1.54

= 0.28 m³

Cement bags = 0.28 ÷ 0.035 ≈ 8 bags

Step 4: Calculate Sand Quantity

Sand = (1.5 / 5.5) × 1.54

= 0.42 m³

Step 5: Calculate Aggregate Quantity

Aggregate = (3 / 5.5) × 1.54

= 0.84 m³

Final Result for 1 m³ M20 Concrete

- Cement: 8 bags

- Sand: 0.42 m³

- Aggregate: 0.84 m³

This is the standard reference calculation used on most sites.

Example Calculation for House Construction

RCC Slab Example

Assume:

- Slab volume = 10 m³

- Mix ratio = M20

Multiply values:

- Cement = 8 × 10 = 80 bags

- Sand = 0.42 × 10 = 4.2 m³

- Aggregate = 0.84 × 10 = 8.4 m³

Always add 3–5% extra for site wastage.

Material Calculation for Different Works

1. Cement, Sand & Aggregate for PCC

- Use M10 or M15 mix

- Cement requirement is lower

- Suitable for leveling and base concrete

2. Material Calculation for Plastering

Plaster mix = 1:6

Thickness = 12 mm

For 1 m² plaster area:

- Cement ≈ 0.04 bags

- Sand ≈ 0.005 m³

Plastering requires careful calculation to avoid cement shortage.

3. Material Calculation for Brick Masonry

Brick masonry (1:6 mortar):

- Cement ≈ 0.25 bags per m³

- Sand ≈ 0.04 m³ per m³ masonry

Brickwork consumes more mortar than people expect.

Common Mistakes to Avoid

- Ignoring dry volume factor

- Using wrong mix ratio

- Forgetting wastage allowance

- Mixing different units (ft³ and m³)

- Blindly trusting contractor estimates

These mistakes can increase construction cost by 10–15%.

FAQs

Q1. How many bags of cement are needed for 1 m³ concrete?

Depends on mix ratio. For M20, around 8 bags.

Q2. Why do we multiply by 1.54?

To convert wet concrete volume into dry material volume.

Q3. Is this calculation valid for all house works?

Yes, for manual mix and basic estimation.

Q4. Should I add extra material quantity?

Yes, add 3–5% for wastage and site handling losses.

Conclusion

Accurate cement, sand & aggregate calculation for house construction is the foundation of cost control and quality work. A few minutes spent on calculation can save thousands in material wastage and delays.

Whether you’re a homeowner, student, or site engineer, understanding these basics helps you:

- Plan materials confidently

- Monitor site consumption

- Avoid disputes and shortages

In construction, calculation is not optional—it is essential.

Latest Articles