In construction, most disputes are not about quality—they are about quantity and payment. One missing line item, one unclear description, or one wrong unit can lead to serious confusion between the client, contractor, and engineer.

That is why a well-prepared BOQ (Bill of Quantities) is one of the most important documents in any construction project.

This guide explains BOQ preparation step-by-step, using practical site logic rather than textbook theory—so you can understand, prepare, or verify a BOQ with confidence.

What Is a BOQ (Bill of Quantities)?

A BOQ (Bill of Quantities) is a detailed document that lists:

- Description of work

- Unit of measurement

- Quantity of each item

It does not fix the rate by itself—but it provides the base on which:

- Contractors quote prices

- Bills are prepared

- Payments are released

BOQ vs Estimate vs Costing

- Estimate: Overall project cost

- BOQ: Item-wise quantities

- Costing: Applying rates to BOQ items

Simply put:

Estimate tells “how much roughly”, BOQ tells “how much exactly”.

Importance of BOQ in Construction

A properly prepared BOQ helps in:

- Transparent tendering

- Fair comparison of contractor quotes

- Accurate billing and measurement

- Cost control and tracking

- Avoiding disputes and variations

According to construction industry studies, projects with clear BOQs experience up to 25% fewer cost disputes.

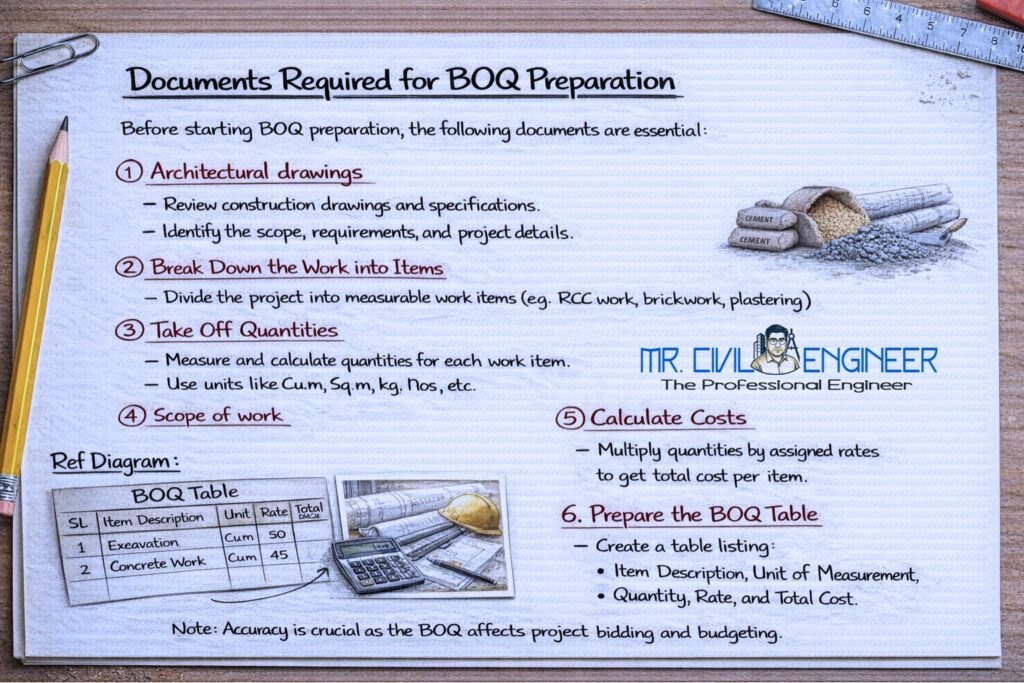

Documents Required for BOQ Preparation

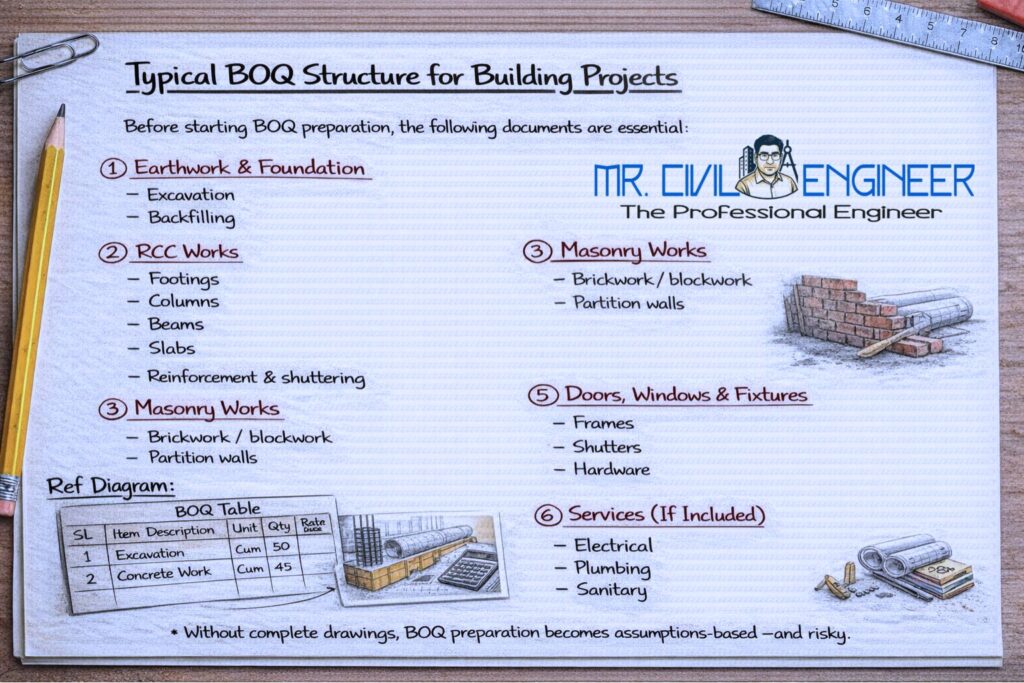

Before starting BOQ preparation, the following documents are essential:

- Architectural drawings

- Structural drawings

- Specifications (materials and workmanship)

- Standard measurement rules (IS / CPWD / local SOR)

- Scope of work

Without complete drawings, BOQ preparation becomes assumptions-based—and risky.

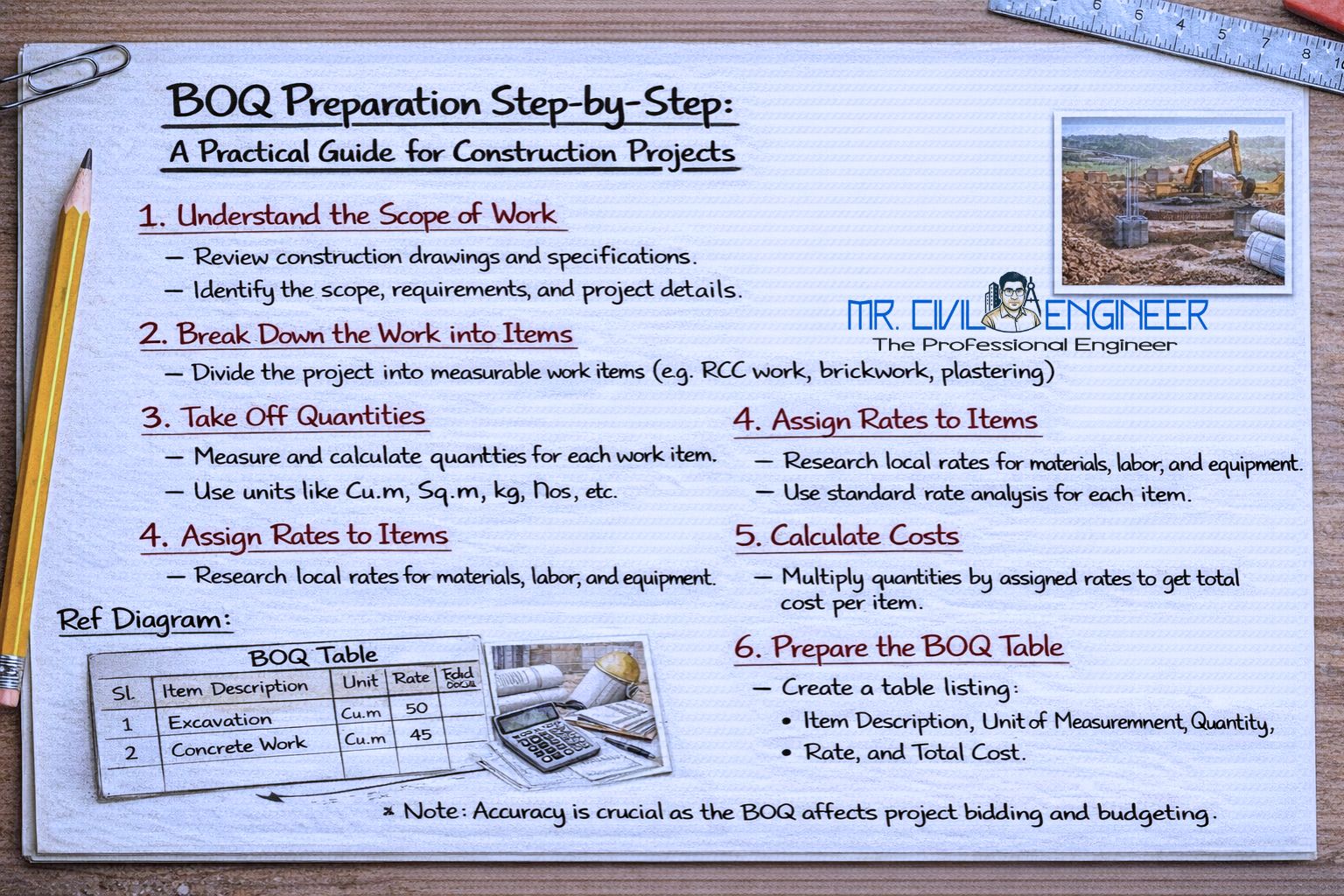

BOQ Preparation Step-by-Step

Let’s break down the BOQ preparation process into simple, logical steps.

Step 1: Study Drawings Thoroughly

Never rush this step.

- Read architectural and structural drawings together

- Understand dimensions, levels, and details

- Note different wall thicknesses, slab types, finishes

A BOQ prepared without fully understanding drawings is guaranteed to contain errors.

Step 2: Divide the Project into Work Sections

Break the project into logical sections such as:

- Earthwork

- PCC

- RCC work

- Masonry

- Plastering

- Flooring

- Doors and windows

- Painting

- Services (electrical & plumbing)

This makes BOQ systematic and easy to check.

Step 3: Quantity Take-Off (Measurement)

This is the core of BOQ preparation.

- Measure quantities directly from drawings

- Use standard formulas (length × breadth × height)

- Follow standard measurement rules

- Avoid overlapping or double counting

Quantities are usually measured in:

- m³ (concrete, brickwork)

- m² (plaster, flooring)

- Running meter (pipes, railings)

- Numbers (doors, fixtures)

Step 4: Select Correct Units

Each item must have the correct unit, such as:

- Concrete – cubic meter (m³)

- Plaster – square meter (m²)

- Reinforcement – kilogram (kg) or tonne

- Doors – numbers

Wrong unit selection can completely distort the BOQ value.

Step 5: Write Clear Item Descriptions

A good BOQ description answers:

- What work is included

- Material specification

- Location or type of work

Poor description:

Brickwork in Super Structure

Good description:

First class brick work in 1:4 cement and coarse sand mortar in super structure including necessary cutting and moulding of bricks as required and including honey comb brick work but for one brick thick add for extra labour over including supply of all materials, labour and T & P etc. required for proper completion of work

Clear descriptions reduce disputes and variation claims.

Step 6: BOQ Formatting

A standard BOQ format includes:

| Item No | Description of Work | Unit | Quantity |

|---|

Rates and amounts may be added later during tendering.

Consistency in format improves readability and professionalism.

Typical BOQ Structure for Building Projects

1. Earthwork & Foundation

- Excavation

- Backfilling

- PCC

2. RCC Works

- Footings

- Columns

- Beams

- Slabs

- Reinforcement & shuttering

3. Masonry Works

- Brickwork / blockwork

- Partition walls

4. Finishing Works

- Plastering

- Flooring

- Painting

5. Doors, Windows & Fixtures

- Frames

- Shutters

- Hardware

6. Services (If Included)

- Electrical

- Plumbing

- Sanitary

BOQ Preparation Example (Conceptual)

Item: RCC slab (M20)

- Unit: m³

- Quantity: Calculated from drawing

- Description: RCC work M20 grade in slab including centering, shuttering, vibration, curing but excluding reinforcement

This clarity ensures everyone prices the same scope.

Common BOQ Preparation Mistakes

- Missing items (especially finishing works)

- Vague item descriptions

- Wrong units of measurement

- Ignoring wastage or construction method

- Copy-pasting BOQs without project relevance

These mistakes are the main cause of:

- Extra items

- Cost escalation

- Contractor-client disputes

FAQs

Q1. Who prepares the BOQ?

Quantity surveyor, civil engineer, or consultant.

Q2. Is BOQ required for small houses?

Yes. Even small projects benefit from BOQ clarity.

Q3. Can BOQ be prepared without drawings?

Not accurately. Drawings are essential.

Q4. Is BOQ same for all contractors?

Yes. Only rates differ—not quantities.

Conclusion

BOQ preparation step-by-step is not just a technical exercise—it is a control mechanism that keeps construction transparent, measurable, and fair.

A good BOQ:

- Protects the client’s budget

- Helps contractors quote fairly

- Makes billing smooth

- Reduces conflicts

In construction, clarity on paper prevents chaos on site.

Related Articles

- Rate Analysis of RCC Work: Step-by-Step Guide with Example

- Plaster Quantity Calculation (Area-Wise): Step-by-Step Guide

- Brickwork Quantity Calculation (With Formula): Step-by-Step Guide

- Cement, Sand & Aggregate Calculation for House: Step-by-Step Guide

- Building Estimation & Costing: A Complete Guide for Accurate Construction Planning