Have you noticed how clients are suddenly asking about “green materials,” EPDs, or carbon footprints—even for small homes? The shift is not a buzzword phase anymore; it is reshaping how engineers, architects, and builders design and specify materials for 2026 and beyond.

Global reports show that the green building materials market is growing at double‑digit rates and is expected to reach hundreds of billions of dollars by 2030, driven by regulations, certification systems, and rising energy costs. That means sustainable construction materials are no longer optional; they are becoming the new normal.

This guide walks through the best sustainable construction materials for 2026, how they work, where to use them, and how to choose the right combination for your next project.

What makes a construction material “sustainable” in 2026?

Not every product with a green label is actually sustainable. For 2026, material choices are being evaluated on a more holistic set of criteria.

Key factors include:

- Low embodied carbon

- How much carbon is emitted during extraction, manufacturing, transport, and installation.

- Low‑clinker cement, engineered timber, recycled steel, and bio‑based materials help cut this significantly.

- Renewable or recycled content and circularity

- Materials made from rapidly renewable resources (bamboo, hemp, bio‑insulation) or recycled inputs (recycled steel, aggregates, reclaimed wood).

- Reusability at end of life is increasingly important as circular economy policies tighten.

- Operational energy performance and durability

- Insulation, airtightness, and thermal mass affect a building’s energy use for decades.

- Durable materials that last longer reduce replacement cycles and waste.

- Health and indoor air quality

- Low‑VOC paints, adhesives, and finishes, along with natural interior materials, protect occupants from harmful emissions.

- Green building standards like WELL and LEED now strongly emphasize indoor environmental quality.

- Certification and transparency

- Environmental Product Declarations (EPDs), eco‑labels, and compliance with frameworks like LEED, BREEAM, and IGBC help verify sustainability claims.

With these criteria in mind, let’s look at the top sustainable construction materials that are set to dominate 2026.

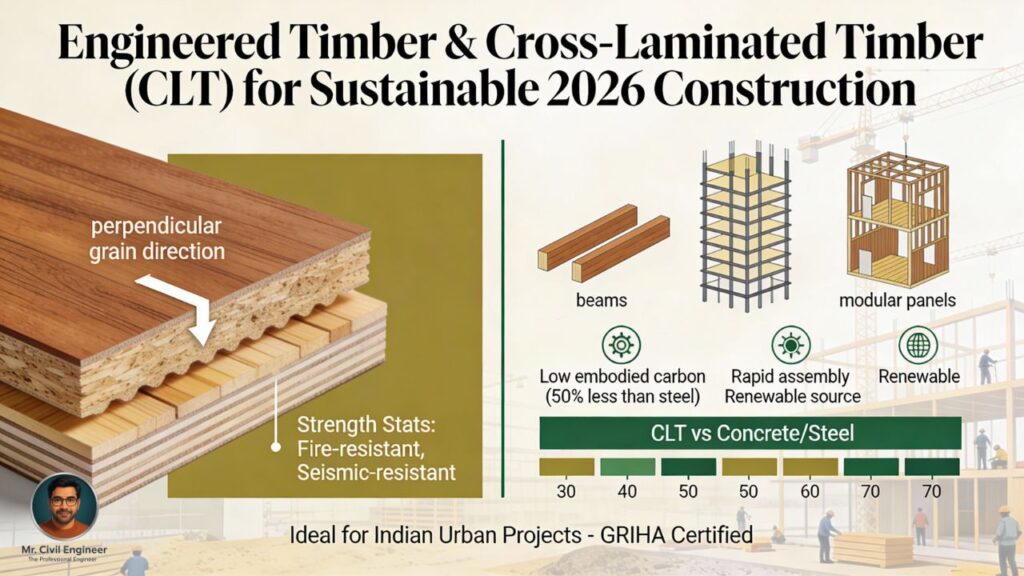

Engineered timber and Cross‑Laminated Timber (CLT)

Engineered timber products like CLT, glulam, and LVL are moving from niche to mainstream in mid‑rise and even high‑rise projects. These products consist of layered, glued timber boards forming strong structural panels and beams.

Why it is sustainable

- Timber stores carbon absorbed during tree growth, effectively locking it into the building for decades.

- Production requires less energy compared to steel and concrete, lowering embodied emissions.

- Lightweight elements reduce foundation sizes and transport emissions.

Where it fits

- Floors, walls, and roofs in residential and commercial buildings

- Hybrid systems with concrete cores or steel frames for taller structures

Points to watch

- Ensure responsibly sourced, certified timber (FSC/PEFC).

- Design carefully for fire resistance and moisture protection in detailing and connections.

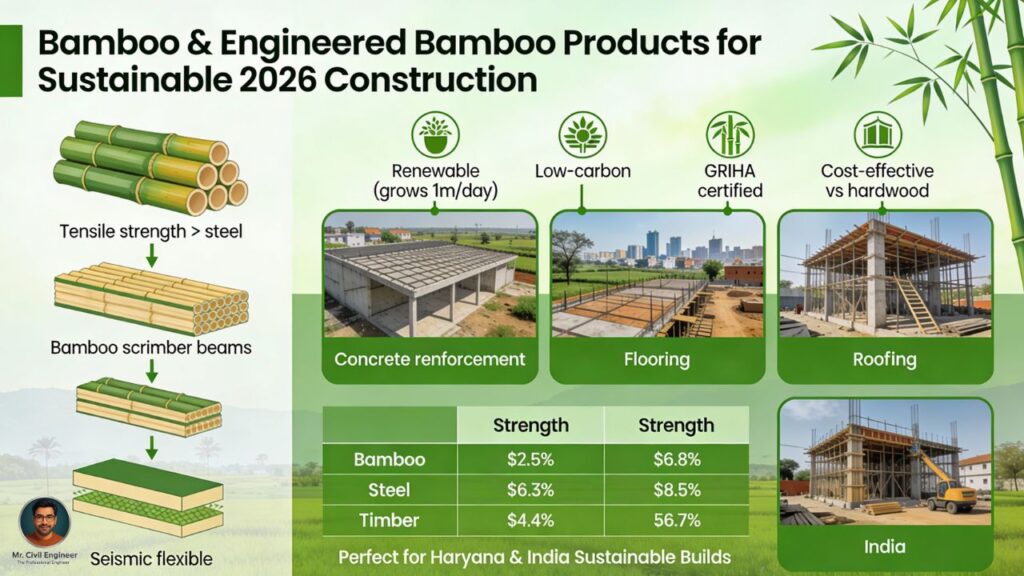

Bamboo and engineered bamboo products

Bamboo is often called “green steel” due to its high strength‑to‑weight ratio and rapid renewability, especially in Asia and tropical regions.

Why it is sustainable

- Bamboo can mature within 3–5 years, far faster than most structural timber.

- It can be processed into engineered products like laminated bamboo boards and beams, offering consistent performance.

Where it fits

- Structural frames in low‑rise buildings, infill, partitions, and trusses

- Flooring, façades, shading devices, and interior finishes

Points to watch

- Proper treatment against moisture, insects, and decay is essential.

- Standardization and codes are still evolving in many jurisdictions.

Hempcrete and other bio‑based concretes

Hempcrete combines hemp Hurds with a lime‑based binder to create lightweight, insulating, non‑load‑bearing wall systems.

Why it is sustainable

- Hemp absorbs CO₂ during growth, and the lime binder can also carbonate over time, giving hempcrete notable carbon‑sequestering potential.

- High thermal and acoustic performance reduces operational energy use.

Where it fits

- External and internal walls as infill to a structural frame (timber, steel, or concrete)

- Energy‑efficient homes, heritage renovations, and low‑rise commercial buildings

Points to watch

- Requires specific details for drying and protection from bulk water.

- Thicker walls compared to masonry may affect usable floor area.

Low‑carbon and carbon‑storing concrete (including Ferrock and bio‑cement)

Concrete is still the backbone of global construction, but its cement content contributes significantly to global CO₂ emissions. In 2026, low‑carbon and carbon‑storing variants will be central to sustainable design.

Key directions

- Low‑clinker cements and supplementary cementitious materials (SCMs) such as fly ash, slag, and calcined clays reduce the percentage of high‑emission clinker.

- CO₂‑mineralizing mixes and carbon‑cured concrete actively bind CO₂ into the material.

- Emerging materials like Ferrock, made from steel dust, can be carbon‑negative and extremely durable.

Why it is sustainable

- Large emission reductions at scale because concrete volumes are huge across infrastructure and buildings.

- Often compatible with existing batching plants and construction techniques, easing adoption.

Recycled steel and “green steel”

Steel is vital for long spans and high‑rise structures but traditionally produced via coal‑based blast furnaces. In 2026, greener pathways are gathering pace.

Why it is sustainable

- Electric‑arc furnaces (EAF) using scrap steel and renewable power dramatically cut emissions relative to conventional production.

- Hydrogen‑based direct reduction can further reduce process emissions, positioning green steel as a long‑term solution.

Where it fits

- Rebar, structural sections, roofing sheets, and cladding systems

- Particularly attractive for projects targeting stringent carbon targets and green certifications.

Points to watch

- Confirm recycled content and EPD data during procurement.

- Costs can vary depending on regional energy mix and incentives.

Recycled aggregates and recycled concrete

Recycled aggregates from demolition waste and old concrete are playing a growing role in sustainable construction as cities aim for circularity.

Why it is sustainable

- Reduces pressure on natural quarries and river sand resources.

- Cuts landfill disposal of construction and demolition waste.

Where it fits

- Non‑structural concrete, sub‑bases, road layers, and, with proper control, structural concrete mixes within code limits.

Points to watch

- Quality control is critical: strength, impurities, and durability must be tested and monitored.

- Codes may limit replacement ratios depending on exposure and structural demands.

Bio‑based and high‑performance insulation

Thermal performance is now a core sustainability metric, and bio‑based insulation options are gaining traction alongside advanced synthetic systems.

Bio‑based options

- Cellulose (from recycled paper), wood fiber, cork, sheep wool, mycelium‑based panels.

Why they are sustainable

- Often made from recycled or rapidly renewable feedstocks.

- Provide good thermal and acoustic performance with relatively low embodied energy.

Points to watch

- Require proper detailing for moisture and pest control.

- Fire performance and treatment must comply with local regulations.

Reclaimed wood and salvaged materials

Instead of always buying new, many 2026 projects will integrate reclaimed timber, bricks, tiles, and even steel components from older buildings.

Why it is sustainable

- Reuse has one of the lowest additional environmental footprints because the material is already manufactured.

- Supports circular economy goals and preserves architectural character.

Where it fits

- Floors, interior finishes, feature walls, façades, and sometimes structural elements after proper assessment.

Points to watch

- Time needed for cleaning, grading, and testing.

- In structural uses, engineering checks and certification are essential.

Sustainable roofing and façade systems

Roofs and façades are now doing more than just shielding buildings; they actively contribute to sustainability goals.

Examples:

- Green roofs: vegetation layers that improve insulation, biodiversity, and stormwater management.

- Cool roofs and reflective coatings: reduce cooling loads and urban heat island effects.

- Recycled metal roofing and façades: durable, recyclable, and often manufactured with high recycled content.

Choosing the right system depends on climate, structural capacity, and maintenance capabilities.

Low‑VOC paints, adhesives, and interior materials

Even a highly efficient building can feel “unhealthy” if interior materials emit harmful VOCs.”

Why they matter

- Low‑VOC or zero‑VOC paints, sealants, and adhesives significantly improve indoor air quality.

- Green standards and conscious clients increasingly specify VOC limits in contracts.

Where to focus first

- Interior walls and ceilings

- Flooring systems and finishes (including adhesives)

- Furniture and built‑in joinery materials

Market trends pushing sustainable materials in 2026

Adopting sustainable materials is no longer just an ethical choice; it is becoming a market and compliance necessity.

- Market growth: Reports estimate the global green building materials market to reach well over USD 350–400 billion around 2025 and nearly double by 2030, with CAGRs above 12–14%.

- Regulation and policy: Carbon pricing mechanisms and trade tools such as the EU’s Carbon Border Adjustment Mechanism (CBAM) create direct economic incentives for low‑carbon materials.

- Certification and investor pressure: LEED, BREEAM, and similar frameworks are now widely recognized by owners and financiers, encouraging the use of certified green materials.

- Digitalization and AI: BIM platforms and AI‑driven tools help compare EPDs, optimize material choices, and simulate lifecycle performance.

For engineers, architects, and builders, this means that choosing sustainable materials is quickly becoming part of mainstream best practice.

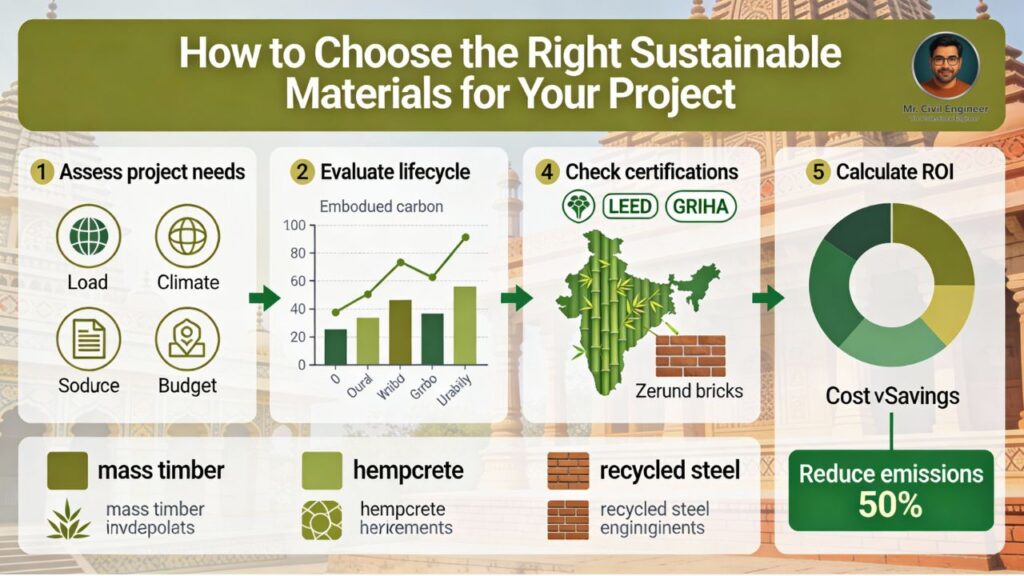

How to choose the right sustainable materials for your project

Given the variety, a simple framework helps.

- Clarify project goals

- Decide whether your primary driver is embodied carbon reduction, operational energy savings, healthier interiors, faster construction, or a mix of these.

- For example, a passive‑style home might prioritize insulation and airtightness, while an urban mid‑rise may focus on low‑carbon concrete and steel.

- Check local context and codes

- Look at local climate, seismic conditions, fire regulations, and material availability.

- In some regions, bamboo or adobe will be natural choices; elsewhere, CLT or recycled steel might be more realistic.

- Compare options using transparent data

- Use EPDs, third‑party certifications, and lifecycle assessment where available.

- Consider lifecycle cost: a slightly higher upfront price for better insulation or durable roofing can pay back through lower energy and maintenance costs.

- Start with “easy wins

- Substitute low‑carbon concrete mixes instead of standard ones.

- Switch to low‑VOC paints and adhesives.

- Add bio‑based or high‑performance insulation in walls and roofs.

- Use recycled aggregates in non‑structural works and reclaimed materials for finishes.

- Communicate benefits to clients

- Translate technical gains into outcomes: lower bills, better comfort, healthier indoor air, and higher resale value.

- Use simple metrics such as percentage reduction in embodied carbon or kWh saved per year.

FAQs

1. Are sustainable construction materials always more expensive?

Not necessarily. Some materials (e.g., simple recycled aggregates or low‑VOC paints) are cost‑comparable, while others (like CLT or green steel) can be slightly more expensive upfront but offer savings through faster construction, lower operational energy, or better durability. Lifecycle cost analysis often shows that many green material choices pay for themselves over time.

2. Can I use sustainable materials with conventional RCC and steel structures?

Yes. Many sustainable materials, such as low‑carbon concrete mixes, recycled steel, bio‑based insulation, and low‑VOC finishes, integrate seamlessly with standard RCC and steel designs. You can start by substituting greener variants without changing the structural system.

3. How do I convince clients to choose sustainable materials?

Link material choices to benefits they care about: lower electricity bills, better indoor air quality for their family or staff, and future‑proofing against stricter regulations and carbon taxes. Sharing case studies, certifications, and simple payback calculations can build trust.

4. Which sustainable materials are easiest to adopt in India or similar markets?

Materials with established supply chains, such as fly ash/slag‑based low‑carbon concrete, recycled steel, bio‑based or mineral insulation, and low‑VOC paints, are typically easiest to adopt first. Bamboo, compressed earth blocks, and hempcrete are also promising where local expertise is available.

Conclusion: Build for 2050, not just for handover day

Sustainable construction materials are no longer experimental; they are increasingly backed by mature supply chains, strong data, and clear business cases. In 2026, the real competitive advantage lies in combining the right materials—low‑carbon concrete, green steel, bio‑based insulation, engineered timber, and healthy interiors—into coherent, buildable designs that meet both performance and budget.

By making informed material choices today, you are not only delivering a project; you are contributing to cities and communities that remain resilient, efficient, and healthy well into 2050.

Recent Posts

- Building Approval Process in India 2026: Step-by-Step Guide

- Civil Engineering Trends in Smart Cities: India 2026 Guide

- How to Use BIM in Civil Projects: Step-by-Step Guide

- Top 10 Tools Every Site Engineer Must Own (With Practical Field Tips)

- Waterproofing Methods for Homes: A Complete Practical Guide