Pouring concrete in hot weather is one of the most challenging tasks on a construction site. When temperatures rise, concrete doesn’t behave the way it does on a pleasant day. It sets faster, loses moisture quickly, and becomes vulnerable to cracks—even before it gains strength.

If you’ve ever seen hairline cracks appear within hours of concreting, chances are hot weather was the silent culprit. This article provides a clear, step-by-step concrete pouring checklist for hot weather, written from a real site-execution perspective.

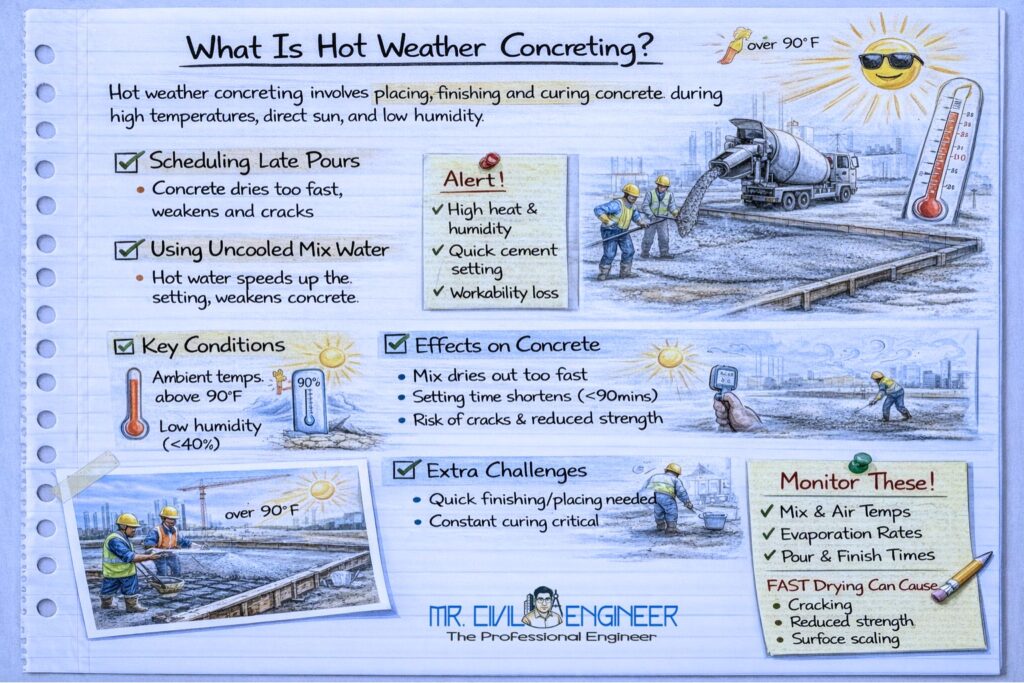

What Is Hot Weather Concreting?

Hot weather concreting refers to concreting operations carried out when ambient temperature, concrete temperature, or wind speed is high enough to negatively affect concrete properties.

As per IS 7861 (Part 1):

Hot weather conditions exist when the temperature is high enough to cause rapid loss of moisture, increased rate of hydration, and reduced workability.

Typically, issues start when:

- Ambient temperature > 30–35°C

- Concrete temperature > 30°C

Why Concrete Fails in Hot Weather

Understanding the problem helps prevent it.

1. Rapid Evaporation of Water

High temperature and wind cause water to evaporate faster than bleeding water can rise.

2. Faster Setting Time

Concrete stiffens quickly, making compaction and finishing difficult.

3. Plastic Shrinkage Cracks

Surface dries faster than internal concrete → cracks appear within hours.

4. Reduced Long-Term Strength

Uncontrolled water loss affects hydration and final strength.

📉 Studies show that concrete placed at higher temperatures can lose 10–20% long-term strength if not properly cured.

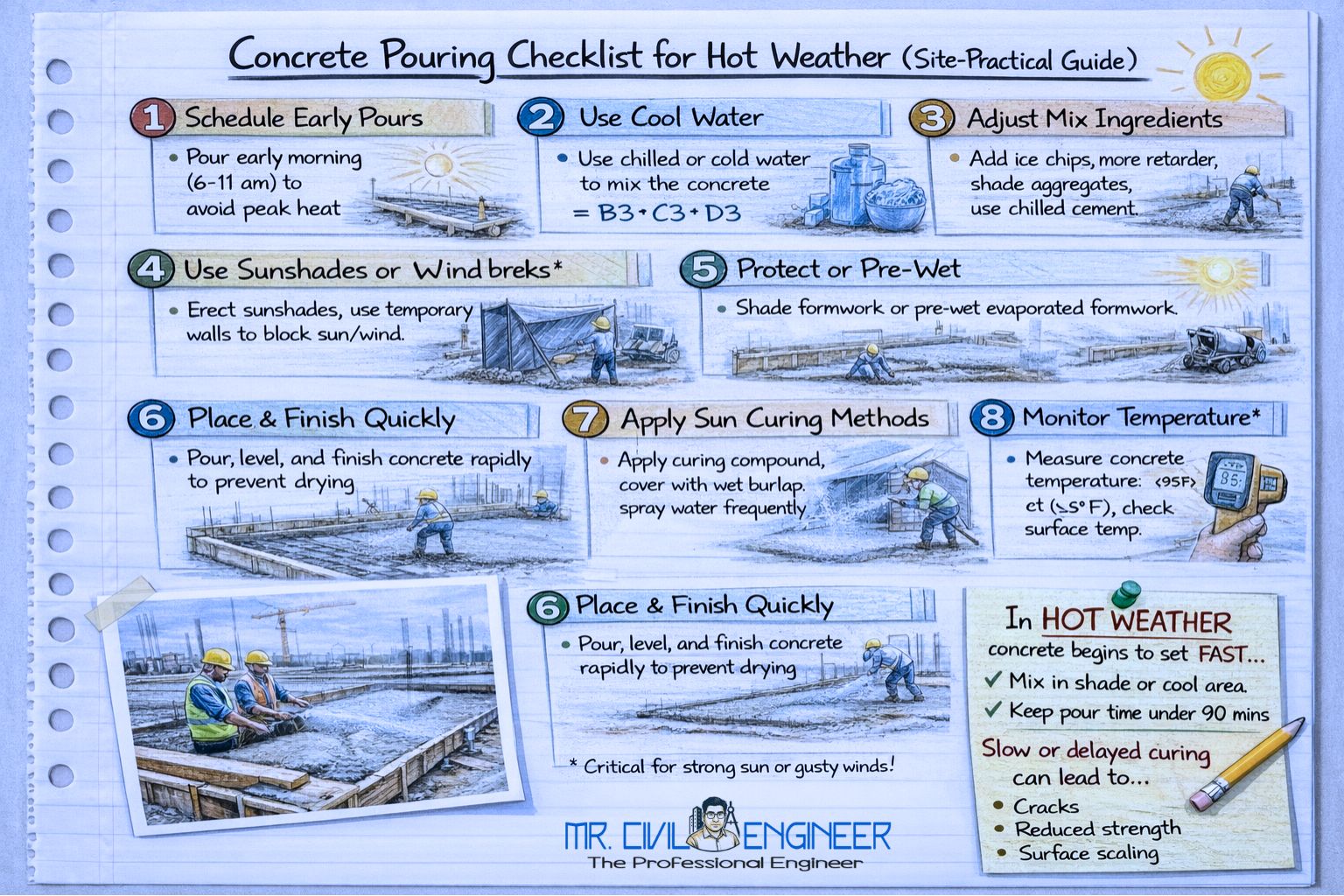

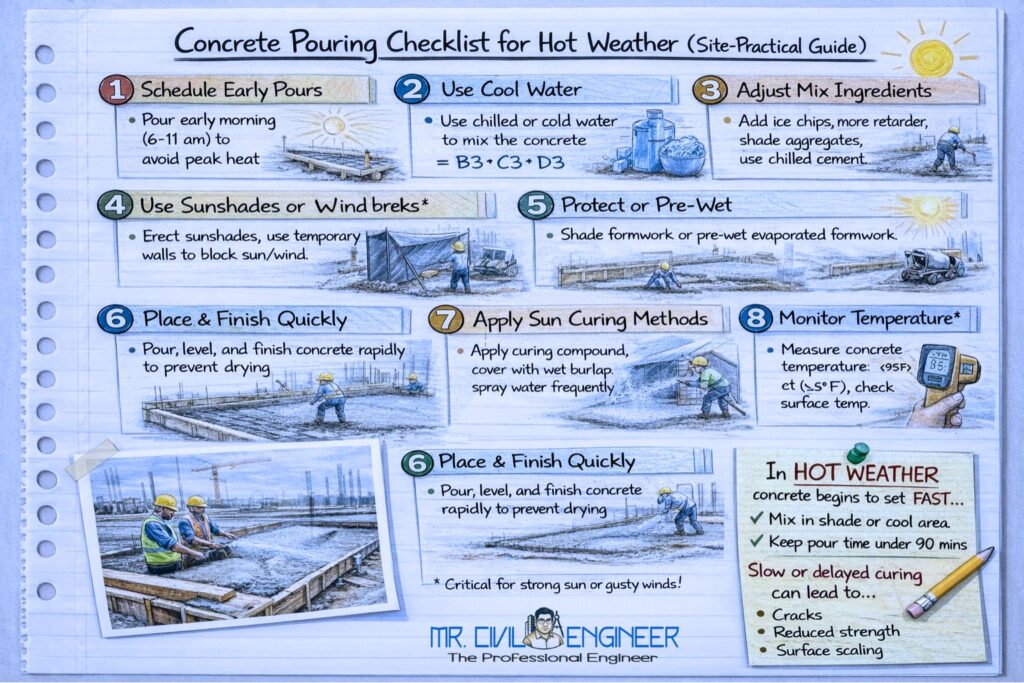

Concrete Pouring Checklist for Hot Weather

Below is a three-stage checklist you can practically use on site.

A. Checklist Before Concrete Pouring (Most Critical)

✅ 1. Weather Planning

- Avoid pouring during peak afternoon hours (12 PM – 4 PM)

- Prefer early morning or night concreting

- Check weather forecast (temperature + wind)

✅ 2. Material Preparation

- Store cement in shaded areas

- Keep aggregates cool and moist (not dripping wet)

- Use chilled water if available

✅ 3. Concrete Mix Planning

- Use lower water-cement ratio with plasticizers

- Avoid high cement content mixes

- Confirm concrete grade and slump in advance

✅ 4. Formwork & Reinforcement Check

- Shuttering should be cool and damp before pouring

- Steel reinforcement should not be hot to touch

- Remove standing water, but keep surfaces moist

📌 Tip: Dry shuttering absorbs water from concrete instantly.

B. Checklist During Concrete Pouring

✅ 1. Control Concrete Temperature

- Concrete temperature should ideally be below 30°C

- Minimize transit time from batching plant to site

- Cover transit mixers if required

✅ 2. Placement & Pouring

- Place concrete immediately after unloading

- Avoid re-tempering (adding water at site)

- Pour in layers, not all at once

🚫 Adding water on site may increase workability but reduces strength permanently.

✅ 3. Compaction (Vibration)

- Use vibrator immediately after placement

- Avoid over-vibration (causes segregation)

- Do not delay compaction due to fast setting

✅ 4. Finishing Operations

- Finish surface as soon as bleeding water disappears

- Avoid excessive trowelling

- Do not sprinkle dry cement or water on surface

C. Checklist After Concrete Pouring

✅ 1. Immediate Curing Is Mandatory

Curing should start as soon as surface hardens.

Best curing methods in hot weather:

- Ponding (for slabs)

- Wet gunny bags

- Continuous sprinkling

- Curing compounds (if water is limited)

✅ 2. Protection from Sun & Wind

- Cover slab with plastic sheets or wet coverings

- Provide wind breaks if needed

- Restrict movement on slab

✅ 3. Extended Curing Duration

- Minimum 7 days for OPC

- Prefer 10–14 days in hot weather

💧 More curing = better strength & durability.

Practical Site Example

On a summer afternoon, slab concreting was done at 38°C without surface protection. Within 6 hours:

- Fine surface cracks appeared

- Concrete surface became powdery

- Cube strength dropped below target

The issue was not the mix—but lack of hot weather precautions.

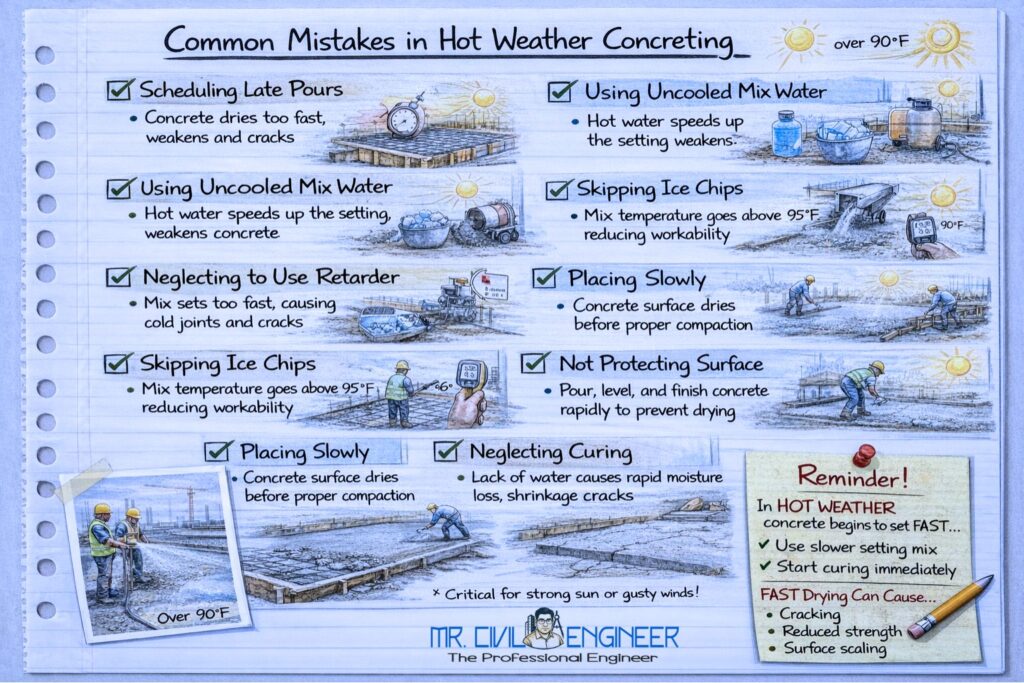

Common Mistakes in Hot Weather Concreting

- Pouring concrete at peak afternoon temperature

- Adding extra water to improve workability

- Delayed curing

- Ignoring wind speed

- Dry formwork and reinforcement

Each of these mistakes increases the risk of plastic shrinkage cracks and low strength.

Frequently Asked Questions (FAQs)

Q1. Can we add extra water in summer?

No. Water addition reduces strength and increases cracking.

Q2. Is night concreting better in hot weather?

Yes. Lower temperature improves workability and hydration.

Q3. Is curing more important in summer?

Absolutely. Hot weather demands longer and stricter curing.

Conclusion

Hot weather doesn’t ruin concrete—poor planning does. By following a proper concrete pouring checklist for hot weather, you can prevent cracks, strength loss, and surface defects even in extreme summer conditions.

Good concrete is not about speed.

It’s about control, timing, and discipline.