Shuttering may look like a temporary arrangement on a construction site, but its impact on structural safety, shape, and strength is permanent. Choosing the right type of shuttering and removing it at the correct time can be the difference between a durable structure and one filled with cracks, deflection, or failure.

If you’ve ever wondered “Which shuttering should I use?” or “When exactly can I remove slab shuttering?”—this guide answers everything in simple, site-practical language.

What Is Shuttering (Formwork)?

Shuttering, also known as formwork, is a temporary mold used to hold fresh concrete until it gains enough strength to support itself.

It serves three critical purposes:

- Gives shape and dimensions to concrete

- Supports wet concrete load

- Maintains alignment and surface finish

In RCC construction, shuttering quality directly affects surface finish, strength, and safety.

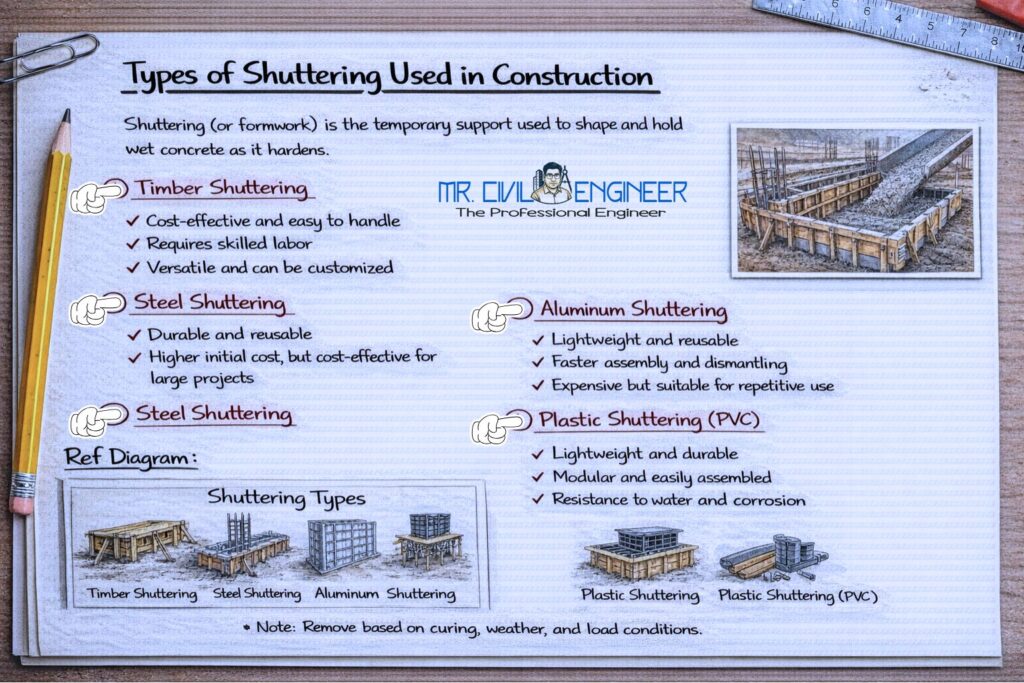

Types of Shuttering Used in Construction

1. Timber (Wooden) Shuttering

Timber shuttering is one of the oldest and most commonly used formwork types.

Advantages:

- Easily available

- Easy to cut and adjust

- Suitable for small projects

Disadvantages:

- Low durability

- Poor surface finish

- High wastage

Best Used For:

Small residential buildings and temporary works.

2. Plywood Shuttering

Plywood shuttering is widely used today due to its smooth finish and better strength.

Advantages:

- Good surface finish

- Reusable (8–10 times)

- Faster work

Disadvantages:

- Edge damage if mishandled

- Requires proper storage

Best Used For:

Slabs, beams, and columns in residential and commercial buildings.

3. Steel Shuttering

Steel shuttering is commonly used in large and repetitive works.

Advantages:

- High strength and durability

- Excellent surface finish

- Can be reused 50+ times

Disadvantages:

- High initial cost

- Heavy and less flexible

Best Used For:

Bridges, large housing projects, infrastructure works.

4. Aluminium (Mivan) Shuttering

Aluminium shuttering is a modern system formwork used for fast construction.

Advantages:

- Very fast execution

- Uniform quality

- Excellent finish

Disadvantages:

- Very high initial investment

- Design changes are difficult

Best Used For:

Mass housing and high-rise projects.

5. Plastic Shuttering

Plastic shuttering is lightweight and reusable.

Advantages:

- Lightweight

- Easy handling

- Corrosion-resistant

Disadvantages:

- Limited load capacity

- Not suitable for heavy RCC work

Best Used For:

Small repetitive structures and low-load applications.

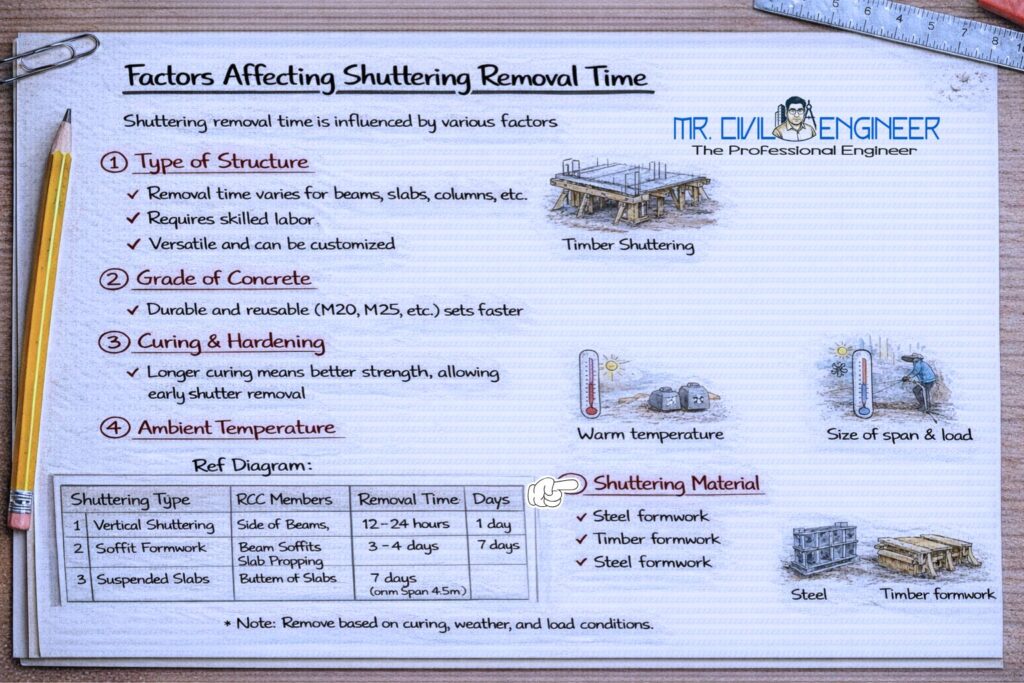

Factors Affecting Shuttering Removal Time

Shuttering removal time depends on several factors:

- Concrete grade (M20, M25, etc.)

- Ambient temperature (hot or cold weather)

- Type of cement used

- Span of slab or beam

- Proper curing practice

Concrete does not gain full strength immediately. As per studies, concrete achieves:

- ~65% strength in 7 days

- ~90% strength in 14 days

- ~100% strength in 28 days

(Source: IS 456:2000 & standard concrete behavior data)

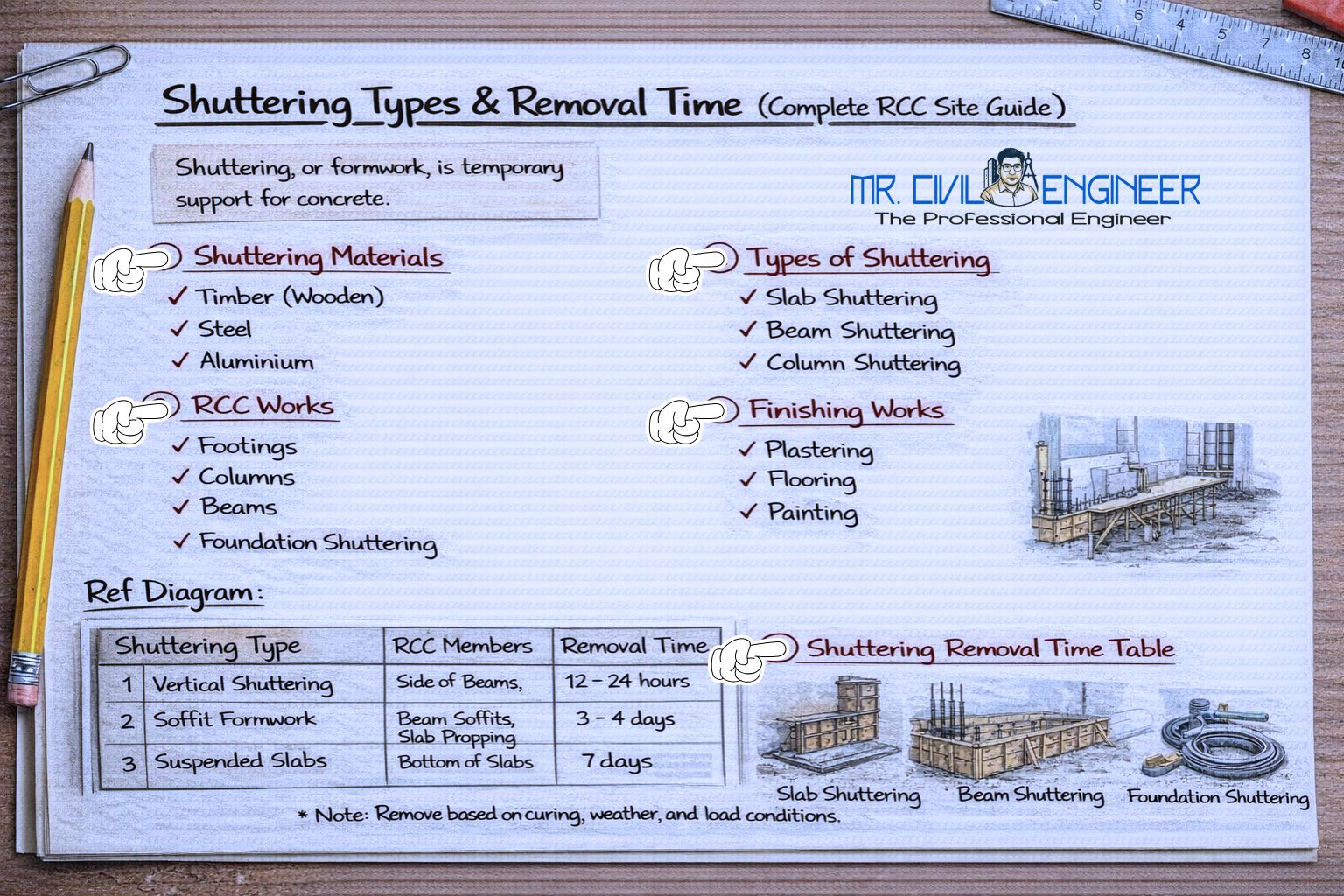

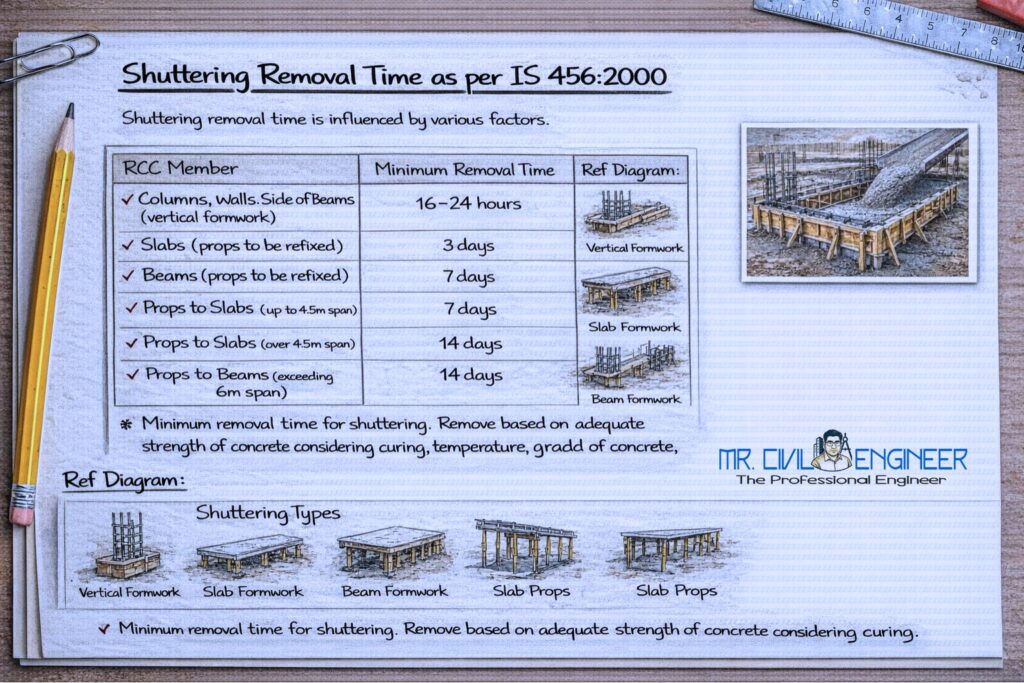

Shuttering Removal Time as per IS 456:2000

Below are standard recommended de-shuttering times:

1. Vertical Formwork (Columns, Walls, Beams Sides)

🕒 24–48 hours

Concrete gains enough strength to retain shape.

2. Slab Soffit Formwork (Props Left Under)

🕒 3 days

Props should remain to support load.

3. Slab Soffit Formwork (Props Removed)

🕒 7 days

Applicable for slabs with span up to 4.5 m.

4. Beam Soffit Formwork (Props Left Under)

🕒 7 days

5. Beam Soffit Formwork (Props Removed)

🕒 14 days

6. Cantilever Slabs & Beams

🕒 14–21 days

Cantilever members are highly sensitive and must never be de-shuttered early.

Practical Site Example

On a residential site, slab shuttering was removed in 4 days instead of 7 due to project pressure. Within weeks:

- Hairline cracks appeared

- Slab deflection was noticed

- Costly repair and strengthening became necessary

This shows that early de-shuttering saves time but costs strength.

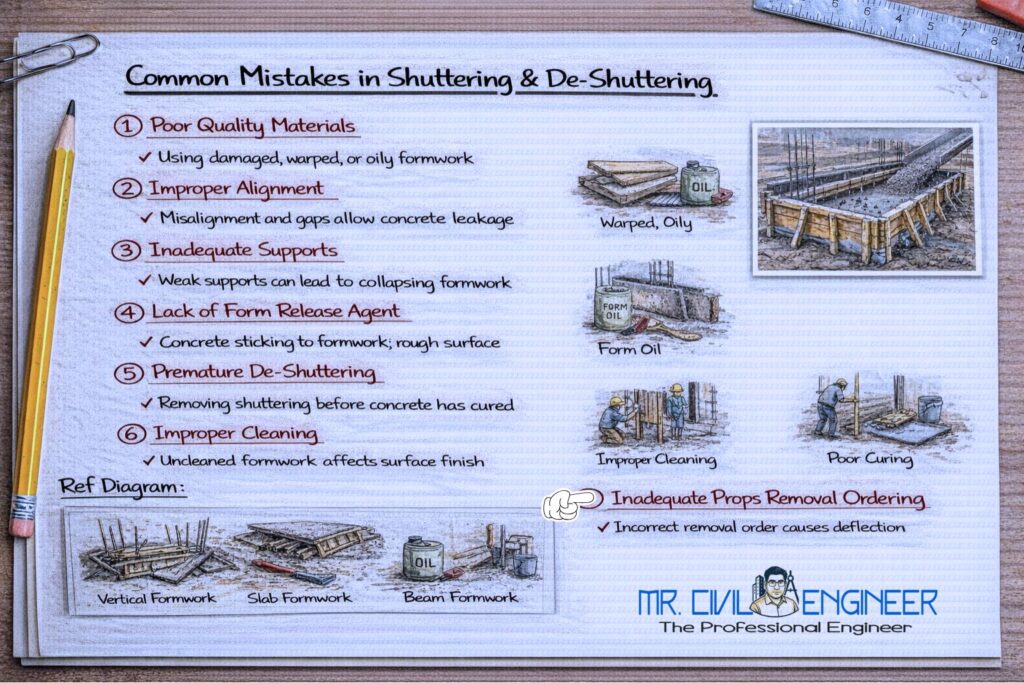

Common Mistakes in Shuttering & De-Shuttering

- Removing props too early

- Using damaged or bent shuttering plates

- Improper alignment and leveling

- Ignoring curing after shuttering removal

- Over-reusing plywood beyond life cycle

Frequently Asked Questions (FAQs)

Q1. Can shuttering be removed early in hot weather?

No. High temperature increases evaporation, not strength.

Q2. Is curing required after shuttering removal?

Yes. Curing must continue for the full recommended duration.

Q3. Which shuttering type is best for residential buildings?

Plywood shuttering offers the best balance of cost, finish, and reuse.

Conclusion

Shuttering may be temporary, but its impact is permanent. Choosing the right type of shuttering and following the correct removal time as per IS code ensures safety, durability, and quality construction.

In RCC work, patience during de-shuttering is a sign of good engineering.

Latest Articles

- Step-by-Step Slab Casting Procedure (Complete On-Site Guide)

- Common Estimation Mistakes on Site: Why Projects Go Over Budget

- Excel Sheet for Civil Engineering Estimation: A Complete Practical Guide

- BOQ Preparation Step-by-Step: A Practical Guide for Construction Projects

- Rate Analysis of RCC Work: Step-by-Step Guide with Example