Almost every construction professional has faced this situation at least once:

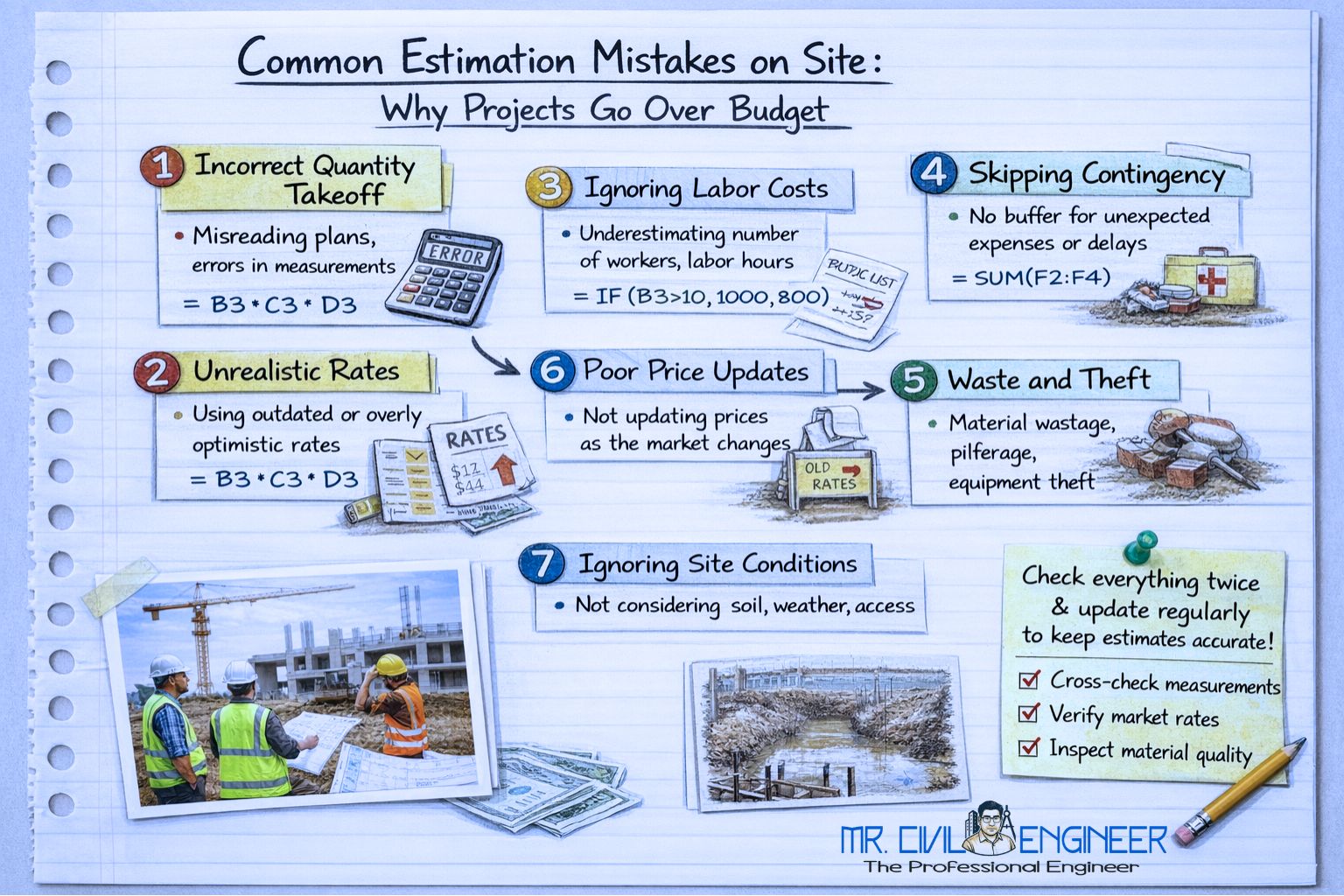

The project started within budget, calculations looked perfect on paper—but halfway through construction, costs started rising unexpectedly.

In most cases, this doesn’t happen because of luxury upgrades or client demands. It happens because of common estimation mistakes on site.

The truth is, estimation errors are rarely dramatic. They are small, silent mistakes that accumulate over time—until the budget collapses.

This article explains the most common estimation mistakes on construction sites, why they occur, and how they can be avoided.

What Is Construction Estimation?

Construction estimation is the process of:

- Calculating quantities of materials

- Estimating labour and equipment requirements

- Predicting the total project cost before execution

A good estimate acts like a financial map. If the map is wrong, even the best execution cannot prevent cost overruns.

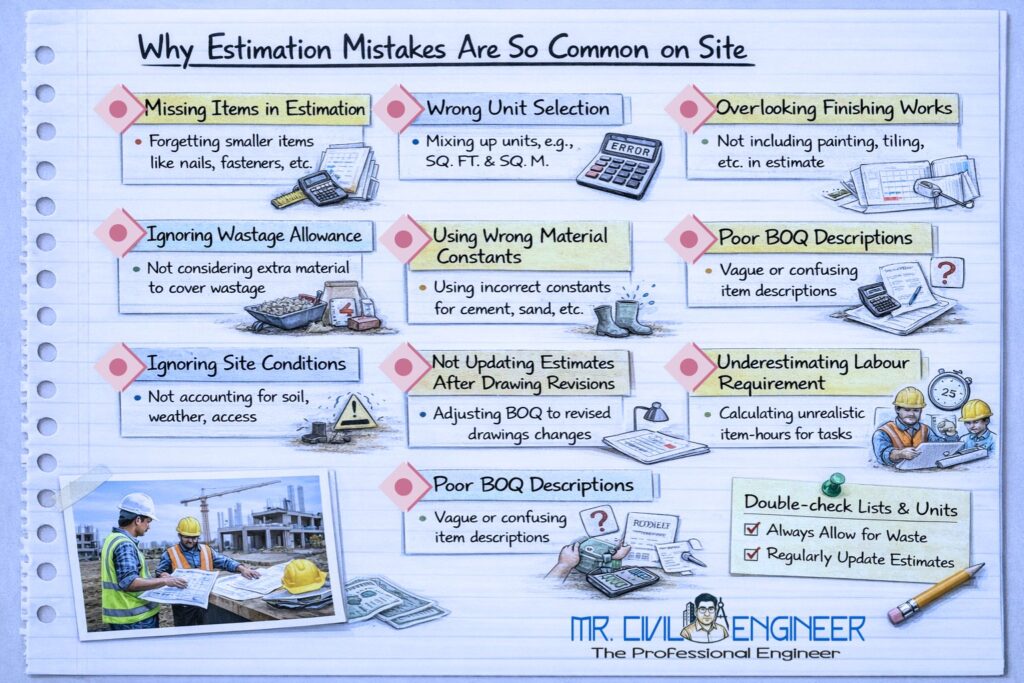

Why Estimation Mistakes Are So Common on Site

Estimation mistakes happen because:

- Site conditions differ from assumptions

- Drawings change frequently

- Time pressure leads to shortcuts

- Estimation is often treated as paperwork, not engineering

Let’s look at the most frequent and costly mistakes seen on real construction sites.

1. Missing Items in Estimation

This is the number one estimation mistake.

Many estimates focus on major works like RCC and masonry but forget:

- Scaffolding

- Curing and protection

- Small concrete works

- Cutting, hacking, and repair work

- Temporary arrangements

Each missing item may seem small, but together they can increase costs by 10–20%.

If it is executed on site, it must appear in the estimate.

2. Wrong Unit Selection

Using the wrong unit creates serious cost distortion.

Common examples:

- Measuring plaster in cubic meters instead of square meters

- Mixing running meters and square meters

- Using “numbers” instead of area-based measurement

Wrong units lead to:

- Incorrect rates

- Confusing bills

- Disputes during payment

Unit selection must always follow standard measurement rules.

3. Ignoring Wastage Allowance

Materials are never used with 100% efficiency on site.

Common wastage sources:

- Cutting and breakage

- Handling losses

- Improper storage

- Rework

Ignoring wastage leads to repeated material orders and higher transport cost.

Typical wastage allowances:

- Cement: 3–5%

- Steel: 2–3%

- Bricks: 5%

- Sand & aggregate: 5–7%

Zero-wastage estimation is unrealistic.

4. Using Wrong Material Constants

Material constants are standard values used in estimation.

Examples:

- Bricks per m³

- Cement bags per m³ concrete

- Steel kg per m³ RCC

Using incorrect constants results in systematic error throughout the estimate.

For example:

- Using 480 bricks instead of 500 bricks per m³

- Assuming low steel percentage without checking drawings

Small constant errors multiply into large quantity differences.

5. Ignoring Site Conditions

Office estimates often ignore real site conditions such as:

- Restricted access

- Manual handling instead of machinery

- Extra labour due to congestion

- Height and lifting requirements

A rate that works on open ground may fail in:

- Urban sites

- Renovation projects

- High-rise construction

Site conditions must always be factored into estimation.

6. Not Updating Estimates After Drawing Revisions

Drawings rarely remain unchanged.

Common mistakes include:

- Using old drawings for estimation

- Ignoring revised structural details

- Missing additional walls or thickness changes

Each revision affects:

- Quantity

- Cost

- Construction method

An estimate that is not updated is already wrong.

7. Overlooking Finishing Works

Many estimates underestimate finishing costs.

Often ignored items:

- Edge detailing

- Skirting

- Grooves and cornices

- Hardware and accessories

- Sealants and minor fittings

Finishing works may look small individually, but together they consume a large portion of the budget.

8. Underestimating Labour Requirement

Labour productivity varies greatly.

Mistakes happen when:

- Standard labour outputs are blindly used

- Weather conditions are ignored

- Skill level of workers is overestimated

Result:

- Delays

- Increased labour cost

- Reduced productivity

Labour estimation must be realistic, not optimistic.

9. Poor BOQ Descriptions

A BOQ item with vague description leads to disputes.

Example of poor description:

RCC work in slab

Better description:

RCC work M20 grade in slab including centering, shuttering, vibration, curing but excluding reinforcement

Poor descriptions create:

- Extra item claims

- Ambiguity in scope

- Payment conflicts

10. Depending Blindly on Contractor Estimates

Contractor estimates may:

- Underquote to secure work

- Exclude certain items intentionally

- Assume lower quality execution

Relying only on contractor estimates without verification is risky.

Independent estimation protects both budget and quality.

11. Mixing Units and Measurement Systems

Mixing:

- Feet with meters

- Inches with millimeters

is a silent but dangerous mistake.

One wrong conversion can distort the entire estimate.

Standardize:

- Units

- Measurement system

- Decimal precision

Consistency prevents errors.

FAQs

Q1. What is the most common estimation mistake on site?

Missing items and ignoring wastage.

Q2. Can estimation mistakes be completely avoided?

No, but they can be significantly reduced with systematic checks.

Q3. Are estimation mistakes more common on small projects?

Yes, because small projects often skip detailed estimation.

Q4. Who is responsible for estimation accuracy?

Primarily the engineer or estimator, supported by site feedback.

Conclusion

Common estimation mistakes on site are rarely caused by lack of knowledge. They are caused by assumptions, shortcuts, and lack of attention to detail.

Good estimation is not about speed—it is about:

- Understanding drawings

- Respecting site realities

- Using correct standards

- Reviewing work carefully

In construction, a small estimation mistake today becomes a big financial problem tomorrow.

The best engineers are not those who build fast—but those who estimate accurately and execute confidently.

Related Articles

- Excel Sheet for Civil Engineering Estimation: A Complete Practical Guide

- BOQ Preparation Step-by-Step: A Practical Guide for Construction Projects

- Rate Analysis of RCC Work: Step-by-Step Guide with Example

- Plaster Quantity Calculation (Area-Wise): Step-by-Step Guide

- Brickwork Quantity Calculation (With Formula): Step-by-Step Guide