Plastering may look like a finishing activity, but it plays a major role in the strength, durability, and appearance of a building. One of the most common site problems is either running out of cement mid-work or ending up with excess sand after plastering is complete.

Both problems usually come from wrong plaster quantity calculation.

This guide explains plaster quantity calculation (area-wise) in a simple, practical way—so homeowners, students, and site engineers can estimate cement and sand accurately before plastering starts.

Basics of Plastering Work

Plastering is the process of applying a thin layer of cement-sand mortar over brick or block masonry to:

- Create a smooth surface

- Protect walls from weather

- Improve durability

- Provide a base for painting

Types of Plastering

- Internal plaster: Inside walls and ceilings

- External plaster: Outside walls (more exposure, often richer mix)

Correct material quantity ensures:

- Uniform thickness

- No cracks or hollow patches

- Controlled construction cost

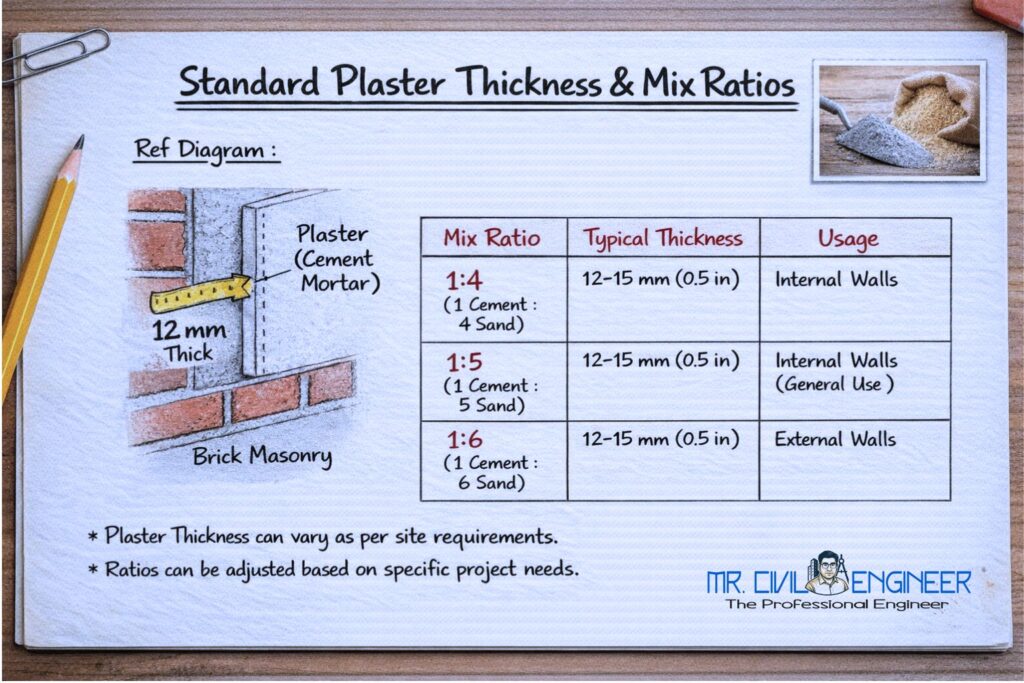

Standard Plaster Thickness & Mix Ratios

Common Plaster Thickness

- Internal walls: 10–12 mm

- External walls: 15–20 mm

- Ceiling plaster: 6–10 mm

Common Cement-Sand Ratios

| Location | Mix Ratio |

|---|---|

| Internal plaster | 1:6 |

| External plaster | 1:4 or 1:5 |

| Ceiling plaster | 1:4 |

A richer mix means more cement consumption.

Key Concepts Before Plaster Quantity Calculation

1. Area-Wise Calculation

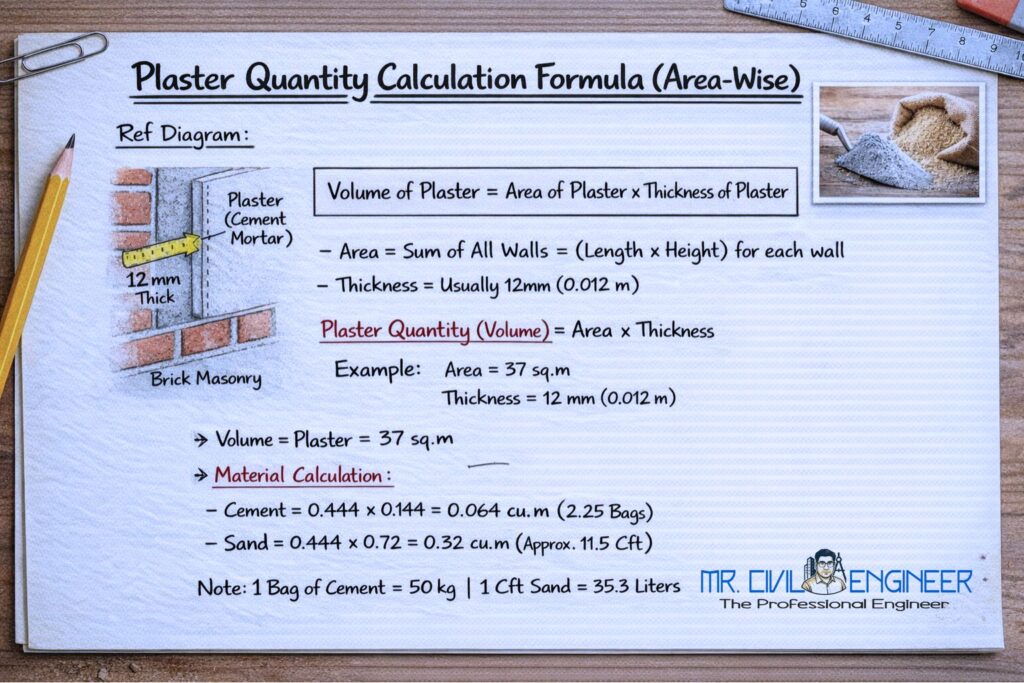

Plastering quantity is calculated based on surface area (m²), not volume of wall.Volume of plaster=Area×Thickness

2. Wet Volume vs Dry Volume

Plaster volume calculated from area is wet volume.

To calculate materials, convert to dry volume:Dry Volume=Wet Volume×1.33

The factor 1.33 accounts for:

- Bulking of sand

- Shrinkage

- Wastage

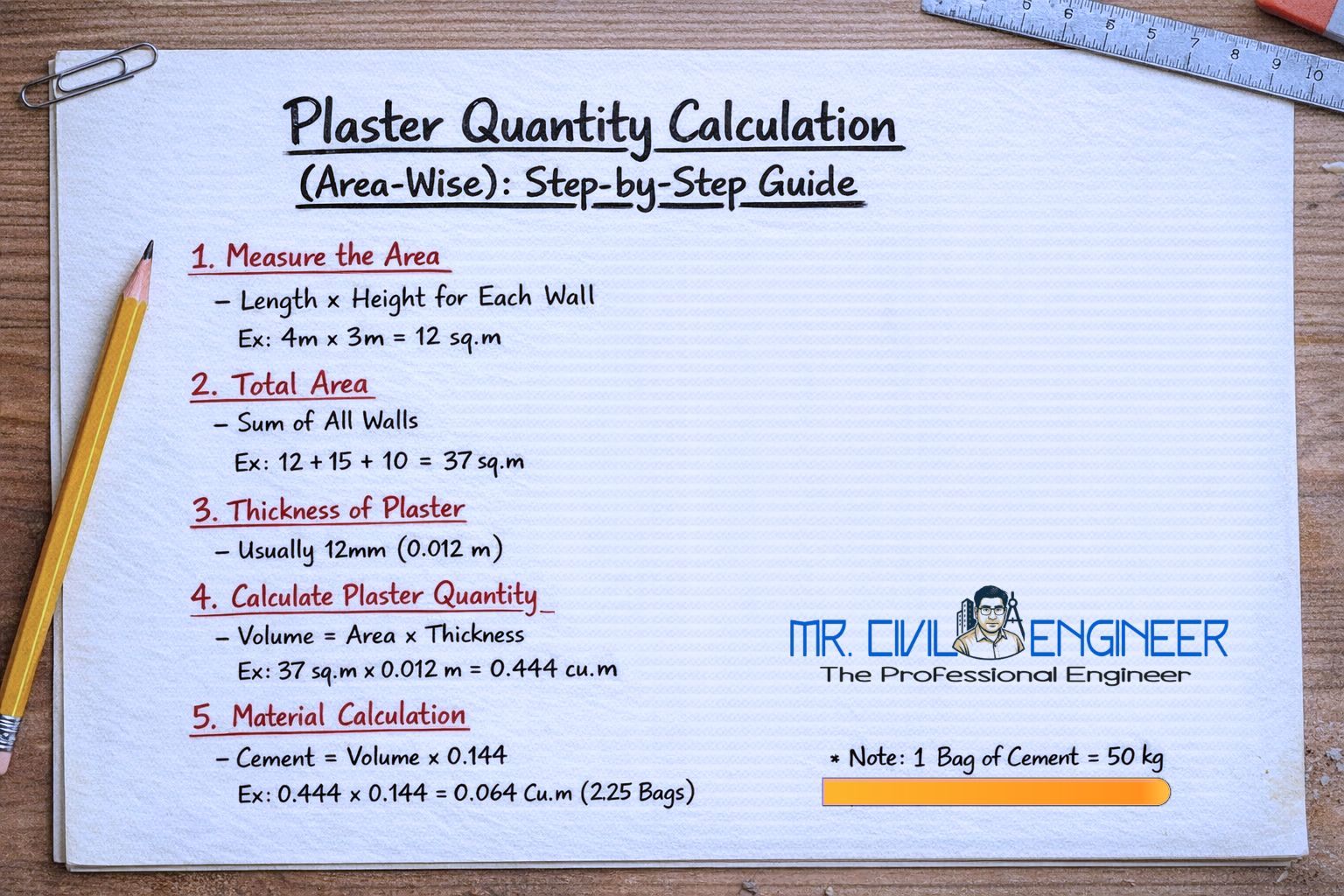

Plaster Quantity Calculation Formula (Area-Wise)

Step-by-Step Formula

- Wet Volume

Area (m²)×Thickness (m)

- Dry Volume

Wet Volume×1.33

- Cement Quantity

Total partsDry Volume×Cement part

- Sand Quantity

Total partsDry Volume×Sand part

Step-by-Step Plaster Calculation (1 m² Example)

Assumptions

- Area = 1 m²

- Thickness = 12 mm = 0.012 m

- Mix ratio = 1:6

Step 1: Wet Volume

1×0.012=0.012m3

Step 2: Dry Volume

0.012×1.33=0.016m3

Step 3: Cement Quantity

Total parts = 1 + 6 = 771×0.016=0.0023m3

Cement bags:0.0350.0023≈0.065 bags

Step 4: Sand Quantity

76×0.016=0.0137m3

Final Quantity for 1 m² (12 mm, 1:6)

- Cement: ~0.06–0.07 bags

- Sand: ~0.013–0.014 m³

Cement & Sand Quantity per m² (Quick Reference Table)

Internal Plaster (1:6)

| Thickness | Cement (bags/m²) | Sand (m³/m²) |

|---|---|---|

| 10 mm | 0.05 | 0.011 |

| 12 mm | 0.06 | 0.014 |

| 15 mm | 0.075 | 0.017 |

External Plaster (1:4)

| Thickness | Cement (bags/m²) | Sand (m³/m²) |

|---|---|---|

| 12 mm | 0.09 | 0.011 |

| 15 mm | 0.11 | 0.014 |

These values are widely used for quick site estimation.

Plaster Quantity Calculation for a Room (Example)

Room Details

- Wall area = 120 m²

- Thickness = 12 mm

- Mix ratio = 1:6

Cement

120×0.065≈8 bags

Sand

120×0.014=1.68m3

Add 3–5% extra for wastage.

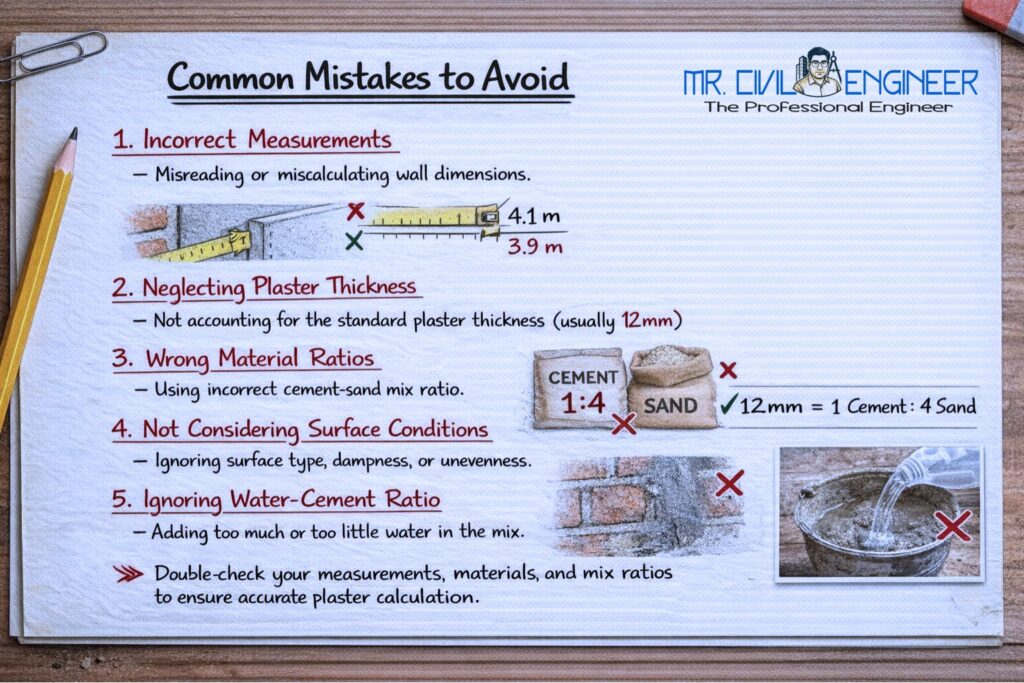

Common Mistakes to Avoid

- Ignoring plaster thickness variation

- Using wrong dry volume factor

- Mixing area and volume methods

- Not separating internal and external plaster

- Forgetting wastage allowance

These mistakes can increase plaster cost by 10–20%.

FAQs

Q1. How much cement is required for plaster per m²?

For 12 mm thick plaster (1:6), about 0.06–0.07 bags per m².

Q2. Why is dry volume multiplied by 1.33?

To account for bulking, shrinkage, and handling loss.

Q3. Is area-wise calculation accurate for plastering?

Yes, it is the most practical method for plaster work.

Q4. Should extra material be added?

Yes, add 3–5% extra for wastage and uneven surfaces.

Conclusion

Accurate plaster quantity calculation (area-wise) is essential for smooth construction and cost control. A small error in thickness or ratio can lead to significant material mismatch on site.

By using simple formulas, understanding dry volume concepts, and applying standard values, anyone can confidently calculate plaster quantities for walls, ceilings, or an entire house.

In finishing work, precision saves money—and quality lasts longer.

Latest Articles

- Brickwork Quantity Calculation (With Formula): Step-by-Step Guide

- Cement, Sand & Aggregate Calculation for House: Step-by-Step Guide

- Building Estimation & Costing: A Complete Guide for Accurate Construction Planning

- RCC Work Checklist for Site Engineers 2026

- Beam Reinforcement Detailing Rules – A Practical Guide for Safe RCC Beams