Ever stood on a site watching fresh concrete pour into a beam, heart racing because one wrong check could crack the whole slab months later? RCC work powers 90% of India’s urban homes, but skipping checklists leads to 20-30% rework costs per project. This ultimate guide arms site engineers with a battle-tested RCC checklist, straight from IS 456 and real-site wisdom, to deliver crack-free structures every time.

Why RCC Checklists Save Sites

RCC combines concrete’s compression strength with steel’s tension power, but poor execution causes honeycombs or collapses. In India, over 25% of building failures trace to RCC flaws like bad laps or curing neglect, hiking costs by ₹50,000+ per floor. A solid checklist ensures compliance, cuts delays, and boosts your rep—think promotions or client trust for that next G+2 villa.

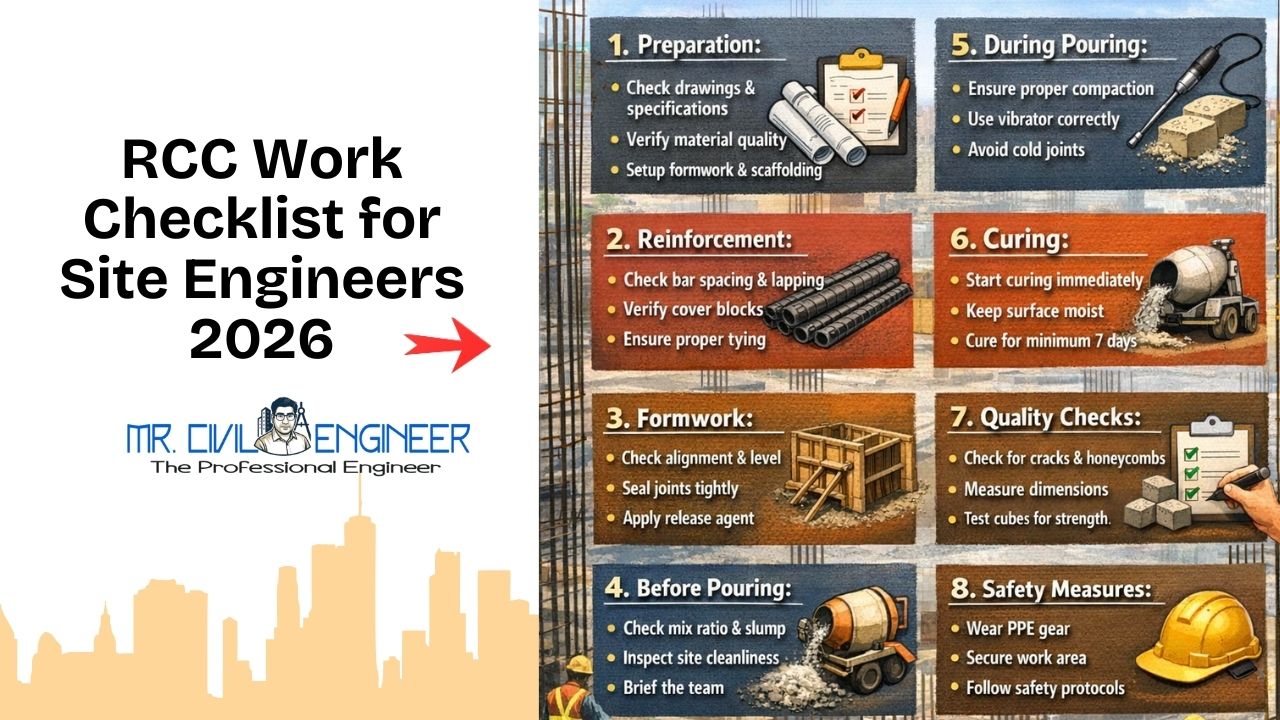

Pre-RCC Preparation Checks

Start strong before steel or shuttering touches ground. Verify soil compaction post-foundation; unstable bases shift loads. Stock cement (check expiry <3 months), aggregates (no silt >5%), and sand (bulking test).

- Confirm mix design approval (M20-M30 for homes).

- Inspect tools: vibrators, slump cones, cube molds ready.

- Clear services like plumbing sleeves fixed, no clashes with rebar. Picture a midnight pour without lights—disaster avoided by pre-checks.

Reinforcement Detailing Checklist

Rebar is RCC’s backbone; mess it up, and beams sag. Use Fe500 steel, clean of rust or oil.

- Spacing, diameter match drawings (e.g., 8mm @150c/c stirrups).

- Laps staggered 40x dia, no bundles >2 bars.

- Clear cover: 20mm slabs, 40mm beams (use 1.5″ blocks).

Like a skeleton, proper binding (2mm wire) prevents shifts—inspect lap zones twice.

Formwork and Shuttering Inspection

Shuttering holds wet concrete; weak props leak slurry. Check plywood edges sealed, no gaps.

- Line, level, plumb with dumpy level; camber for spans >4m.

- Bracing every 1m, props on 600mm grid.

- Oil surfaces evenly, free of nails. A leaning form once cost a Delhi site ₹2 lakh in refix—level it right.

Concrete Production and Testing

Fresh mix is king; bad batch ruins all. Slump 75-125mm for M25.scribd

- Grade per design, water-cement ratio <0.45.

- Cube molds (150mm) from 3 spots per 20m³.

- No segregation in transit mixer. Thumb rule: 1 bag cement yields 0.035m³.

During Concreting Checklist

Pour like clockwork to avoid cold joints. Layer 300-500mm max.

- Drop height <1.5m, no free fall.

- Vibrate 15-20s per spot, no honeycomb.

- Surface screed level, two carpenters on standby. Imagine monsoon pour—cover cubes immediately.

Post-Concreting and Curing

Curing builds 70% strength in 7 days; skip it, cracks spiderweb.

- Pond water 14 days slabs, 21 days beams (IS 456).

- De-shutter: sides 3 days, bottom 14-21 days.

- Test 7/28-day cubes (>85% target). Non-compliant? Core test or demo.

Common RCC Mistakes and Fixes

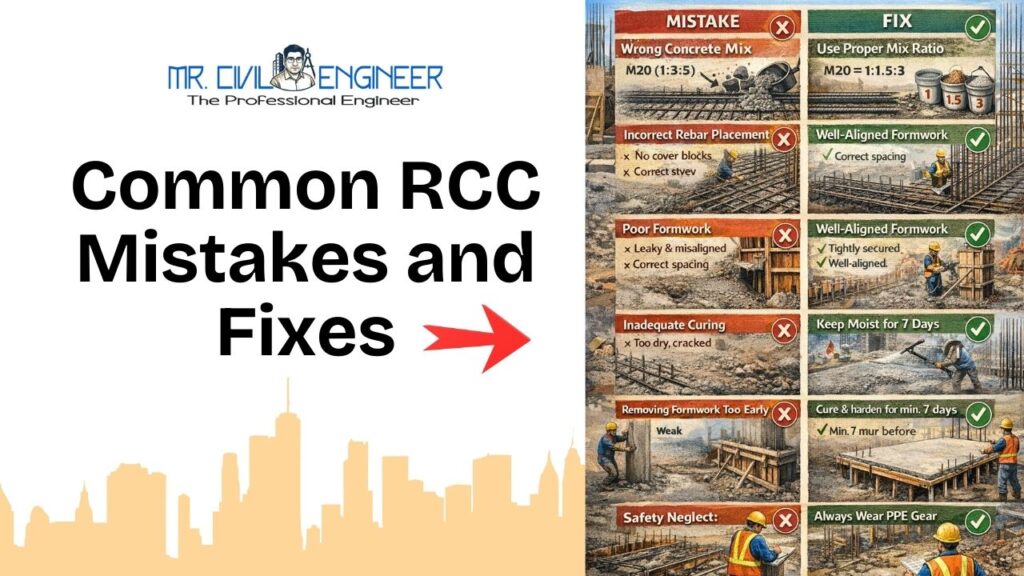

| Mistake | Impact | Fix |

|---|---|---|

| Insufficient cover | Corrosion | Add blocks, recheck all. |

| Poor vibration | Honeycomb | Retrain masons, extra passes. |

| Short curing | Cracks | Extend ponding, gunny bags. |

| Wrong laps | Weak joints | Stagger 50x dia min. |

| Wet slump excess | Segregation | Adjust water, retest. |

Real story: A Mumbai G+1 beam failed lap check, fixed pre-pour—saved ₹1 lakh vs. break-recast.

Frequently Asked Questions

What’s the daily RCC checklist for site engineers? Focus pre-reinforcement, slump, vibration; log everything.

IS code for RCC cover in slabs? 20mm footings/slabs, 25mm beams (IS 456:2000).

How to check rebar laps? 40-50x dia, staggered 1.5x lap apart.

Minimum curing for columns? 14 days full saturation.

Slab slump test frequency? Every 20m³ or truck.

What if cube fails 28-day? Investigate, possibly non-destructive tests.

Beam vs slab shuttering time? Beams 21 days bottom, slabs 14.

Print this checklist, laminate for site use, and turn inspections into instinct. Your next RCC pour won’t just pass—it’ll impress architects and owners alike.