If you’re involved in house construction—whether as an engineer, contractor, or homeowner—steel quantity calculation for slab is one of the most important skills you must understand. Steel alone can account for 20–25% of the total RCC cost, and even small mistakes can lead to big financial losses or structural risks.

So how do you calculate slab steel correctly—without confusion or guesswork?

Let’s break it down step by step, using simple language, real examples, and site-proven methods.

Why Steel Is Critical in RCC Slabs

Concrete is strong in compression but weak in tension. Steel reinforcement takes care of tensile stresses, temperature effects, and shrinkage cracks. As per Bureau of Indian Standards (IS 456:2000), proper reinforcement is mandatory to ensure safety and durability.

In slabs, steel is provided mainly as:

- Main reinforcement (load-carrying)

- Distribution reinforcement (crack control & load sharing)

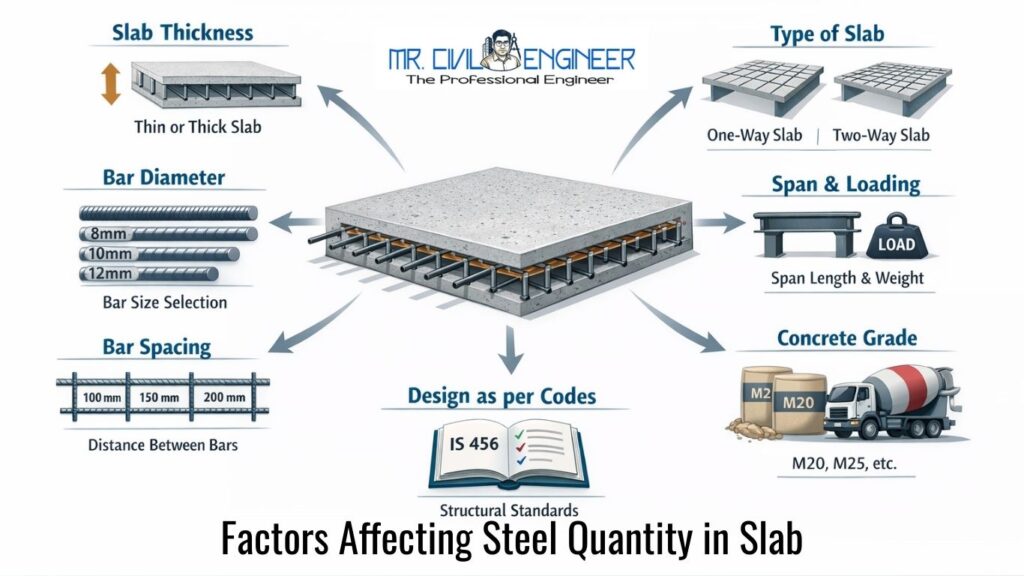

Factors Affecting Steel Quantity in Slab

Steel quantity is not fixed. It varies based on:

- Slab Thickness – Thicker slabs require more steel

- Bar Diameter – 8 mm, 10 mm, or 12 mm bars

- Bar Spacing – 100 mm, 150 mm, or 200 mm

- Type of Slab – One-way or two-way

- Design Load & Span

That’s why relying blindly on thumb rules can be risky.

Thumb Rule for Steel Quantity in Slab

For quick estimation, the following thumb rules are commonly used in India:

- Steel Percentage Method:

- Slab steel ≈ 0.8% to 1.2% of concrete volume

- Steel per Square Meter:

- One-way slab: 7–8 kg/m²

- Two-way slab: 8–10 kg/m²

👉 Thumb rules are useful only for rough budgeting, not for final execution.

Step-by-Step Steel Quantity Calculation (Manual Method)

Let’s calculate steel the correct way.

Step 1: Slab Area

Room size = 4 m × 5 m

Slab area = 20 m²

Step 2: Assume Reinforcement

- Main bars: 10 mm @ 150 mm c/c

- Distribution bars: 8 mm @ 200 mm c/c

- Clear cover = 20 mm

Step 3: Number of Bars

- Main bars = (5000 ÷ 150) + 1 ≈ 34 bars

- Distribution bars = (4000 ÷ 200) + 1 ≈ 21 bars

Step 4: Cutting Length

- Main bar length ≈ 4.0 – 0.04 = 3.96 m

- Distribution bar length ≈ 5.0 – 0.04 = 4.96 m

Step 5: Weight Calculation

Steel weight formula:

Weight (kg) = (D² / 162) × Length

- 10 mm bar weight ≈ 0.617 kg/m

- 8 mm bar weight ≈ 0.395 kg/m

Main steel

= 34 × 3.96 × 0.617 ≈ 83 kg

Distribution steel

= 21 × 4.96 × 0.395 ≈ 41 kg

✅ Total slab steel ≈ 124 kg

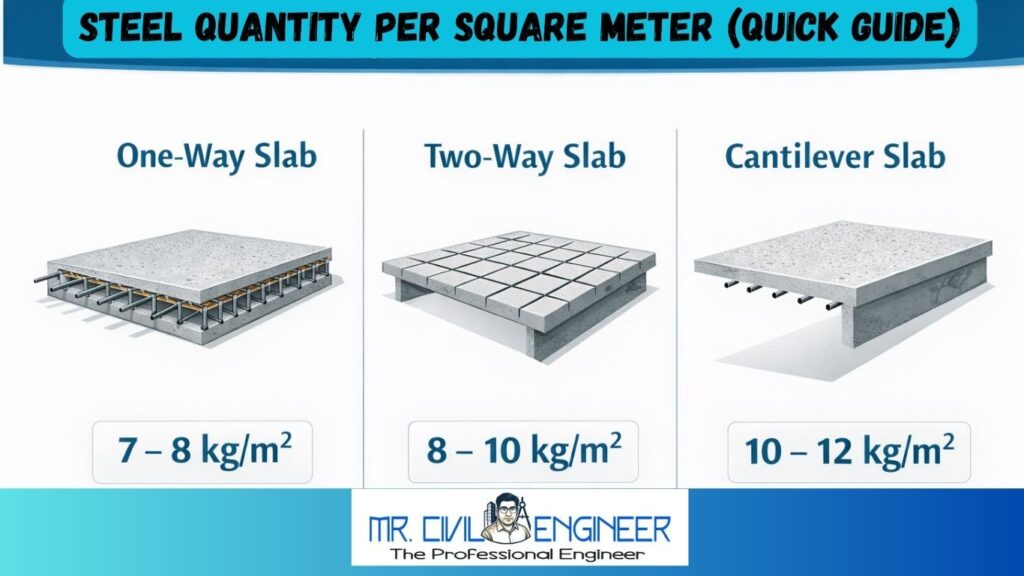

Steel Quantity per Square Meter (Quick Guide)

| Slab Type | Steel Quantity |

|---|---|

| One-way slab | 7–8 kg/m² |

| Two-way slab | 8–10 kg/m² |

| Cantilever slab | 10–12 kg/m² |

Common Mistakes to Avoid

- ❌ Ignoring concrete cover

- ❌ Wrong spacing interpretation

- ❌ Forgetting laps and wastage (add 3–5%)

- ❌ Blindly trusting thumb rules

FAQs

Q1. How much steel is required per sqft of slab?

👉 Around 0.6–0.8 kg/sqft, depending on design.

Q2. Is thumb rule safe for construction?

👉 No. Thumb rules are only for approximate estimation, not execution.

Q3. Why does slab steel vary from project to project?

👉 Due to span, load, slab type, and design requirements.

Conclusion

Understanding steel quantity calculation for slab empowers you to:

- Control construction cost

- Verify contractor estimates

- Avoid steel wastage

- Ensure structural safety

Whether you’re a student, site engineer, or homeowner, mastering this calculation puts you one step ahead on site.

👉 Pro Tip: Always cross-check with structural drawings and codes before execution.

Latest Articles

- Concrete Mix Ratio Table (M10 to M30)

- Footing Design Basics (Isolated & Combined) – A Practical Guide

- Column Size for G+1 & G+2 Buildings (Residential Guide)

- Slab Thickness Calculation (One-Way & Two-Way) – Complete Guide

- Load Calculation for Residential Buildings: A Practical Guide for Slabs, Beams, and Columns