Ever poured concrete only to watch it crack or fail under load a few months later? You’re not alone—many builders and homeowners face this frustration from guessing mix ratios. This guide breaks down the concrete mix ratio table for M10 to M30 grades, using standard Indian proportions from IS 456:2000, so you get reliable strength every time.

Whether fixing a patio or building a home foundation, knowing exact ratios saves money and headaches. Let’s dive into the essentials.

What Are Concrete Grades?

Concrete grades like M10 to M30 refer to the characteristic compressive strength in N/mm² after 28 days of curing. The “M” stands for mix, followed by the strength number—M10 hits 10 N/mm², ideal for basic work.

Up to M20, these are nominal mixes with fixed ratios of cement, sand, and aggregate. From M25-M30, switch to design mixes tailored via lab tests for precision. Proper grading ensures durability against weather and loads.

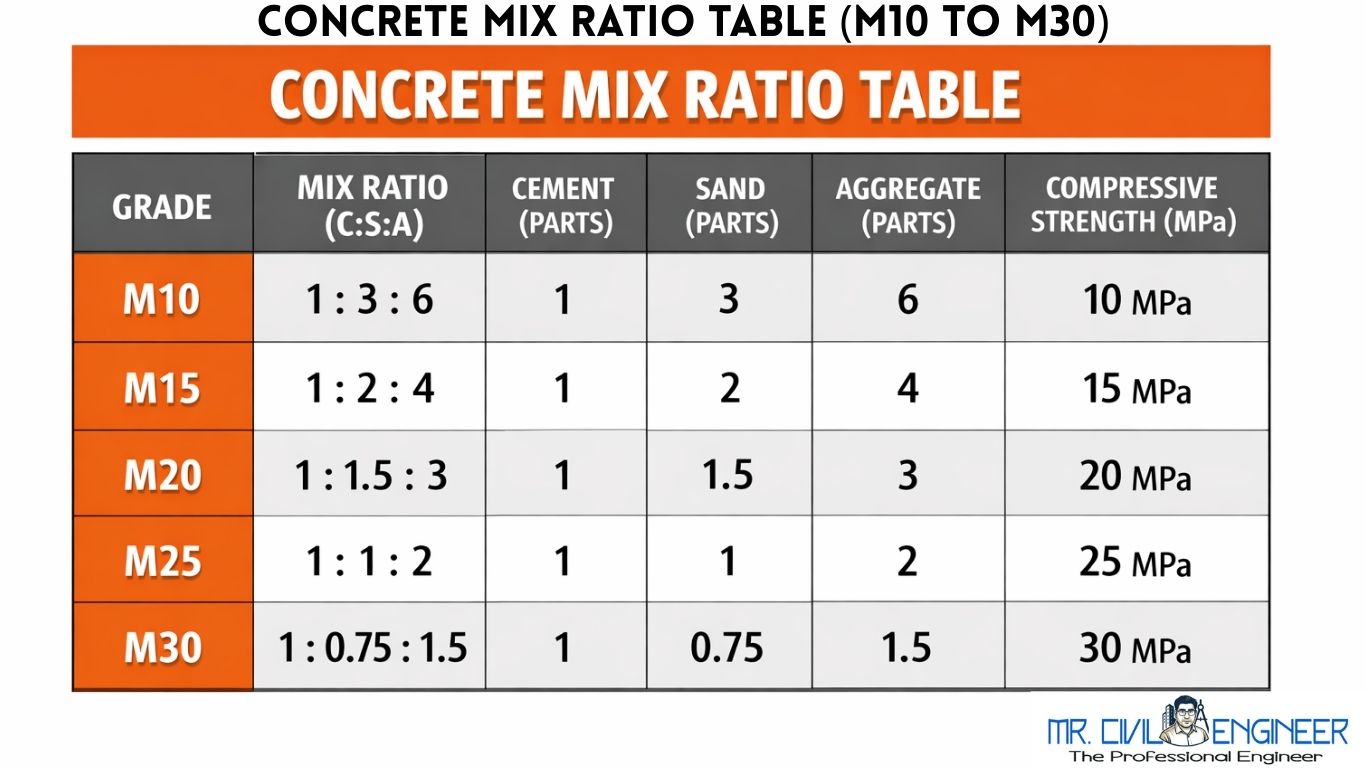

Concrete Mix Ratio Table (M10-M30)

Here’s the go-to table for nominal proportions (cement : sand : aggregate by volume). Always measure by weight for accuracy, and aim for a water-cement ratio of 0.45-0.6.

| Grade | Mix Ratio (Cement: Sand: Aggregate) | Strength (N/mm²) | Typical Water-Cement Ratio |

|---|---|---|---|

| M10 | 1 : 3 : 6 | 10 | 0.55-0.60 |

| M15 | 1 : 2 : 4 | 15 | 0.50-0.55 |

| M20 | 1 : 1.5 : 3 | 20 | 0.50 |

| M25 | 1 : 1 : 2 | 25 | 0.45-0.50 (design mix) |

| M30 | Design mix (e.g., 1:0.75:1.5 approx.) | 30 | 0.40-0.45 (lab designed) |

These ratios assume 53-grade OPC cement and well-graded aggregates. For M30, consult IS 10262 for site-specific design.

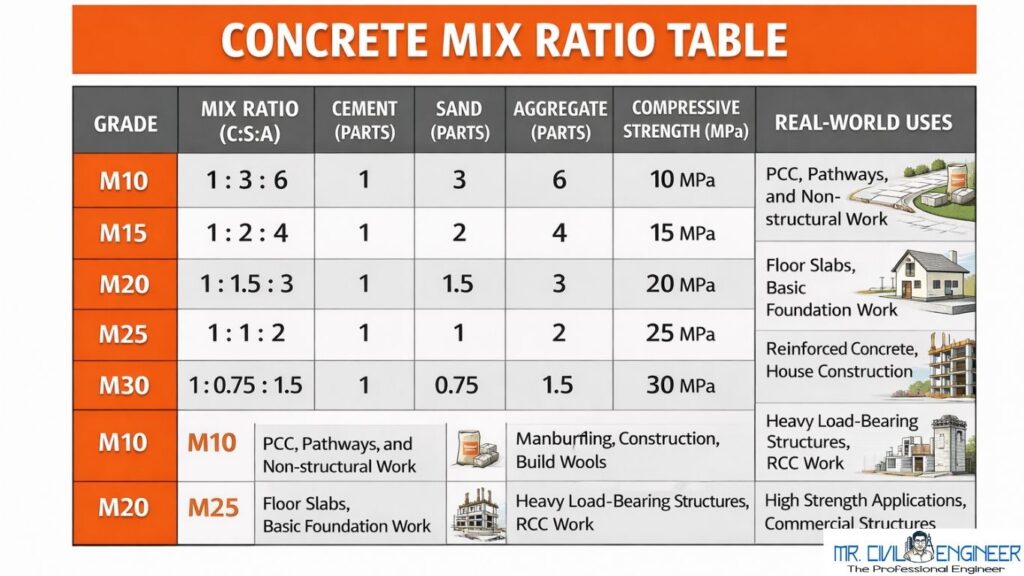

Real-World Uses for Each Grade

Pick the right grade to match your project’s demands—using M10 for a beam is like building a house on sand.

- M10: Perfect for plain cement concrete (PCC) like flooring or bedding. Great for non-structural garden paths where loads are light.

- M15: Steps up for PCC in foundations or pavements. Handles light foot traffic without cracking.

- M20: The workhorse for residential RCC—slabs, beams, columns. Most homes use this for balanced strength and cost. Imagine a sturdy two-story house standing firm for decades.

- M25: For critical RCC in commercial buildings or heavy slabs. Boosts durability in humid areas.

- M30: High-strength for bridges, high-rises, or prestressed elements. Requires pro mix design for max performance.

Stats show M20-M25 cover 70% of Indian residential projects, cutting failures by ensuring proper strength.

Step-by-Step: Mixing Concrete Right

Follow these steps for pro results at home.

- Gather materials: Use clean river sand, 20mm crushed aggregate, and fresh cement.

- Measure precisely: For M20, mix 1 bucket cement, 1.5 sand, 3 aggregate. Add water slowly.

- Dry mix first: Combine cement, sand, aggregate evenly.

- Add water gradually: Target workable slump (75-100mm). Too much weakens it—like diluting soup.

- Mix thoroughly: Use a machine or hoe for 2-3 minutes. Test by forming a ball that holds shape.

- Pour and cure: Place immediately, cover, and wet-cure for 7-28 days.

Pro tip: Add plasticizers for better flow without extra water.

Key Factors for Strong Concrete

Water-cement ratio rules—lower means stronger but harder to work. IS 456 mandates max 0.55 for M20 in moderate exposure.

Other tips:

- Use graded aggregates to fill voids.

- Fresh cement only—old stuff loses 20% strength.

- Avoid over-vibration, which separates mix.

Common mistake: Eyeballing ratios leads to 15-30% strength loss.

FAQs

What’s the M20 concrete mix ratio for slabs?

1:1.5:3, 1 Cement, 1.5 Coarse Sand and 3 20mm Stone grit with 0.5 water-cement ratio.

Nominal or design mix for M30?

Design mix only—lab-tested for exact needs.

Can I use these for RCC?

M15+ yes, but M20 minimum for beams/slabs.

Difference between M20 and M25?

M25 is richer (1:1:2), 25% stronger for heavier loads.

This concrete mix ratio table arms you with proven proportions for M10 to M30. Start small, measure accurately, and watch your projects thrive. For large builds, team up with engineers to nail design mixes.bangurcement+1

Latest Articles

- Footing Design Basics (Isolated & Combined) – A Practical Guide

- Column Size for G+1 & G+2 Buildings (Residential Guide)

- Slab Thickness Calculation (One-Way & Two-Way) – Complete Guide

- Load Calculation for Residential Buildings: A Practical Guide for Slabs, Beams, and Columns

- 12 Common Mistakes in House Planning (And Smart Fixes)