Picture this: a robot lays 400 bricks an hour with perfect mortar joints, while a drone scans the site for rebar misalignment—all without a single worker climbing scaffolding. Construction sites are evolving from manual labor to smart collaboration, where robots handle the dull, dirty, and dangerous tasks.

Robot-assisted construction techniques use AI-powered machines to support human teams, boosting speed by 30-50% and cutting accidents in a $10 trillion industry facing labor shortages. From Indian high-rises to global prefabs, these tools promise precision and efficiency. This guide breaks down the top techniques, real benefits, and how to get started.

What Are Robot-Assisted Construction Techniques?

These aren’t sci-fi fantasies but practical tools blending human skill with machine precision. Robots assist rather than replace workers, tackling repetitive tasks on dynamic sites.

Key categories:

- Tele-operated humanoids: Remote-controlled for hazardous jobs like welding.

- Autonomous arms/bots: Fixed or mobile for bricklaying, rebar tying.

- Drones and scanners: Real-time inspection via LiDAR/AI.

- 3D printers: Layer-by-layer building of walls or modules.

In 2026, expect hybrids: wheeled bases with humanoid arms for stability on rough terrain.

Top Robot-Assisted Techniques for Civil Engineers

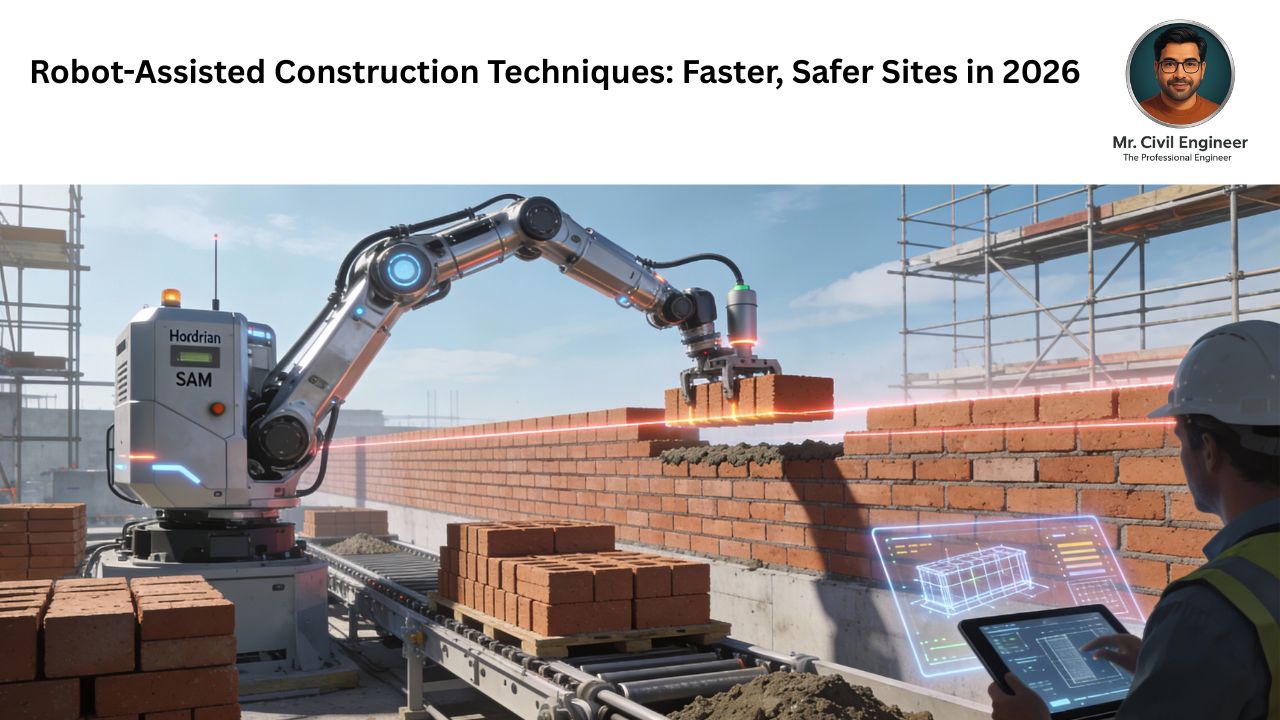

Robotic Masonry and Bricklaying

Machines like SAM (Semi-Automated Mason) or Hadrian X grab bricks, apply mortar, and position them with laser-guided accuracy.

- How it works: AI vision aligns bricks; operator oversees via joystick.

- Best for: Low-rise walls, facades in residential projects.

- Gains: 3-5x faster than manual, consistent quality.

In India, pilots show promise for monsoon-proof masonry without weather delays.

Automated Welding and Rebar Fabrication

Robots weld rebar baskets or steel frames on-site, like Skanska’s systems that cut transport waste. ABB arms handle heavy lifts in tight spaces.

- Process: Sensors map rebar, AI plans welds; human approves.

- Ideal use: RCC columns, bridges, high-rises.

- Impact: 15-38% faster production, safer for workers.

Material Handling and Transport Robots

Autonomous carts or drones ferry steel, concrete blocks across sites, dodging obstacles via GPS/AI.

- Features: Real-time inventory tracking, predictive delivery.

- Sites: Large campuses, highways where forklifts struggle.

3D Printing and Modular Prefab Robots

AuAr’s timber bots assemble blocks off-site; giant printers extrude concrete walls.

- Workflow: Design in BIM, robot prints/assembles modules.

- Benefits: 30% less waste, customizable homes.

Perfect for India’s affordable housing push.

Drones and AI Inspection Bots

Noether scans sites with LiDAR for hazards, progress tracking.

- Daily use: Weekly flyovers detect cracks, verify alignments.

- Edge: Reduces rework by 20%

Humanoid Hybrids for Versatile Tasks

Tele-operated bipeds climb scaffolds, tie rebar, or inspect heights.

- 2026 trend: Semi-autonomous for repetitive jobs.

Proven Benefits with Real Data

Safety first: Robots handle 80% of high-risk tasks, slashing injuries. Intelligent City’s prefab line saw 38% speed gain, 30% waste cut.

Productivity jumps: AI predicts material needs, optimizes paths. Market projection: Humanoid construction robots grow at high CAGR through 2035 due to labor gaps.

Sustainability: Less waste, precise cuts mean greener builds aligning with IGBC goals.

Economic wins: Initial costs drop as tech matures; ROI in 6-12 months for mid-size firms.

Challenges and How to Overcome Them

High upfront costs? Lease robots or start with drones ($5K-20K).

Training gap: 1-2 week programs; pair bots with skilled masons.

Site chaos: Use rugged hybrids with dust/light sensors.

Adoption roadmap:

- Audit repetitive tasks (e.g., 40% of brickwork).

- Pilot on one zone (parking structure).

- Integrate with BIM for digital twins.

- Train via ISARC-style workshops.

Real-World Success Stories

In Canada, Autovol’s timber robots boosted roof prefab efficiency. India’s modular firms use similar for mid-rises, cutting timelines 25%. Globally, Nether drones ensure zero-safety incidents on scans.

These prove robots thrive in real conditions.

2026 Outlook: AI Twins and Beyond

Digital twins simulate robot paths; full task autonomy nears for welding/masonry. Conferences like ISARC 2026 spotlight India-relevant advances. Expect 20-30% site adoption in urban projects.

FAQs

What are the best starter robots for small Indian sites?

Drones for inspection, compact bricklaying arms—low cost, high ROI.

Do robots replace civil engineers?

No, they free you for design/oversight; humans handle complexity.

How much do construction robots cost in India?

Drones: ₹4-15 lakh; full arms: ₹50 lakh+, with leasing options.

Are they monsoon-ready?

Rugged models with IP67 ratings handle dust/rain.

Safety improvements from robots?

Up to 50% fewer accidents by avoiding heights/heavy lifts.

Conclusion: Embrace Robots for Tomorrow’s Builds

Robot-assisted construction techniques turn labor shortages into advantages, delivering safer, faster projects that stand out in bids. Start with one technique—drones or prefab arms—and scale as confidence grows. Your next site could set the standard for 2026 smart construction.

Trending Posts

- Civil Engineering Trends in Smart Cities: India 2026 Guide

- How to Use BIM in Civil Projects: Step-by-Step Guide

- Top 10 Tools Every Site Engineer Must Own (With Practical Field Tips)

- Waterproofing Methods for Homes: A Complete Practical Guide

- Building Approval Process in India 2026: Step-by-Step Guide