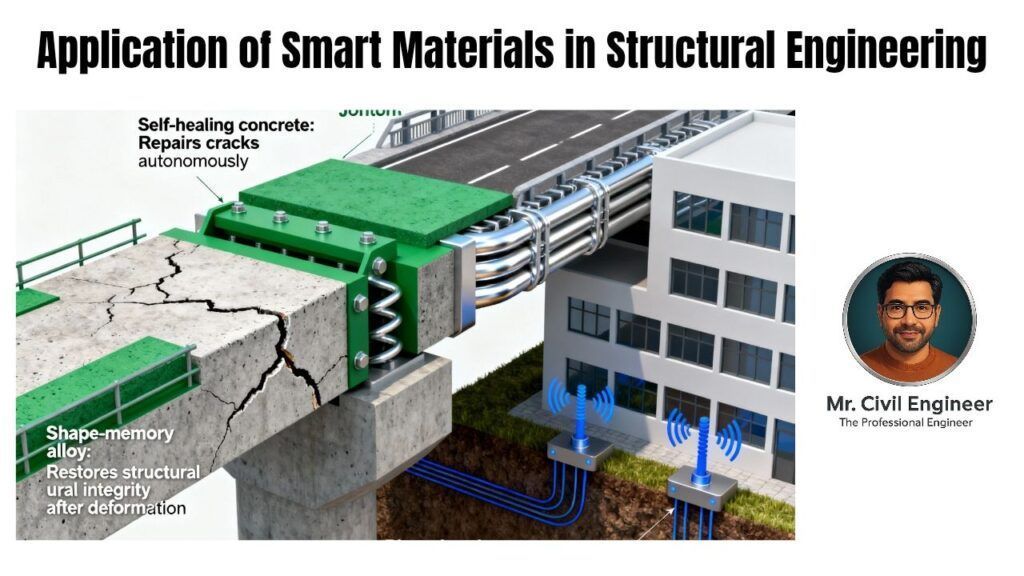

Imagine a bridge sensing its own fatigue cracks and tightening reinforcement bars autonomously before failure. No longer science fiction, smart materials make structures “alive”—sensing damage, adapting to loads, and self-repairing. As aging infrastructure faces earthquakes and climate extremes, application of smart materials in structural engineering promises safer, longer-lasting builds.

stress, temperature, or electricity. From shape memory alloys (SMAs) in seismic zones to piezoelectric sensors monitoring skyscrapers, this guide explores key applications, real examples, and implementation tips.

What Makes a Material “Smart”?

Smart materials exhibit reversible changes in properties:

- Sensing: Detect strain/vibration (piezoelectrics).

- Actuating: Generate force/motion (SMAs).

- Self-aling: Repair microcracks autonomously.

- Adaptive: Tune stiffness/viscosity (rheological fluids).

Unlike passive steel/concrete, they enable “smart structures” with embedded intelligence, cutting maintenance 30–50%.

Shape Memory Alloys (SMAs): Seismic Saviors

SMAs like NiTi (Nitinol) or cost-effective Fe-Mn-Al “remember” shapes via phase transformation (martensite-austenite).

Key properties:

- Shape memory effect (SME): Deform at low temp, recover via heating (up to 8% strain).

- Super elasticity: Recover >10% strain at room temp without heat.

Applications:

- Prestressing rebars: Heat post-cast to tension concrete (e.g., Fe-SMA in UHPC beams, no jacks needed).

- Seismic retrofitting: SMA braces dissipate quake energy, self-center (Japan bridges reduced residual drift 70%).

- Crack closure: Wires contract to seal 0.8mm gaps in concrete.

Example: New Zealand’s SMA-reinforced columns survived 7.8 Mw quake with minimal damage.

Pros/Cons: High fatigue life; but ₹5000–10,000/kg limits to critical elements.

Piezoelectric Materials: Sensing & Actuation Powerhouses

Piezoelectrics (PZT, PVDF) convert mechanical stress to voltage (direct effect) or vice versa (converse).

Structural roles:

- SHM sensors: Embed in beams/bridges for strain mapping, damage detection (e.g., Lamb waves spot 1mm cracks).

- Active vibration control: Patches damp oscillations (H∞ control suppressed drone vibes completely).

- Energy harvesting: Floor piezo tiles power sensors (1m² generates 7W).

Real-world: Golden Gate Bridge piezo arrays monitor cable fatigue real-time.

| Property | Application | Benefit |

|---|---|---|

| Direct Piezo | Crack detection | Early warning |

| Converse Piezo | Actuators | Vibration suppression |

Costs: ₹200–500/patch; scalable via wireless networks.

Self-Healing Concrete: Autonomous Repair

Concrete cracks inevitably, but smart variants heal autonomously.

Mechanisms:

- Bacterial: Bacillus spores + Ca-lactate precipitate CaCO3 in wet cracks (heals 0.8mm in 60 days).

- Capsule-based: Polymers/microcapsules rupture, fill voids.

- Autogenous: Unhydrated cement hydrates (hairline only).

Apps: Marine piers, tunnels (Delft ship lock walls healed post-salt exposure).

Stats: Extends life 50+ years; reduces repairs 40%.

Challenges: Viability in dry climates; 10–20% strength premium.

Rheological Fluids: Adaptive Damping

Magnetorheological (MR) fluids: Iron particles in oil stiffen under magnetic fields (viscosity ×1000 in ms).

Electro-rheological (ER): Similar, via voltage.

Uses:

- Base isolators/dampers: Tune for wind/quakes (tall buildings cut sway 30%).

- Smart bridges: Variable stiffness bearings.

Example: Taiwan high-speed rail MR dampers handle typhoons.

Emerging Applications & Challenges

- Fiber optic sensors: Distributed strain in dams (Bragg gratings).

- Hybrids: SMA-piezo concrete for “sense-act-repair” loops.

Hurdles:

- Cost (2–5x traditional).

- Durability/codes (ACI 561 emerging).

- Integration: Embed early via BIM.

2026 trends: AI-driven SHM, scalable bacterial mixes.

FAQs

SMA vs traditional steel rebar?

SMA self-centers post-quake; steel yields permanently.

Self-healing concrete lifespan?

Heals multiple cycles; bacteria viable 200+ years.

Cost-benefit for piezos?

ROI in 2–5 years via prevented failures.

Conclusion

Application of smart materials in structural engineering transforms vulnerable infrastructure into resilient, self-aware systems. SMAs brace against quakes, piezos whisper warnings, self-healers mend silently—ushering proactive maintenance.

Embrace them for seismic India, aging bridges, green retrofits. Research, pilot, standardize—the future of structures senses, adapts, endures.

Recent Posts

- House Construction Tips in India 2026: A Practical Guide for First-Time Home Builders

- Best Sustainable Construction Materials for 2026: Build Greener, Smarter, and Future‑Ready

- Green Infrastructure Design Tips: Practical Ideas for Cooler, Flood‑Safe Cities

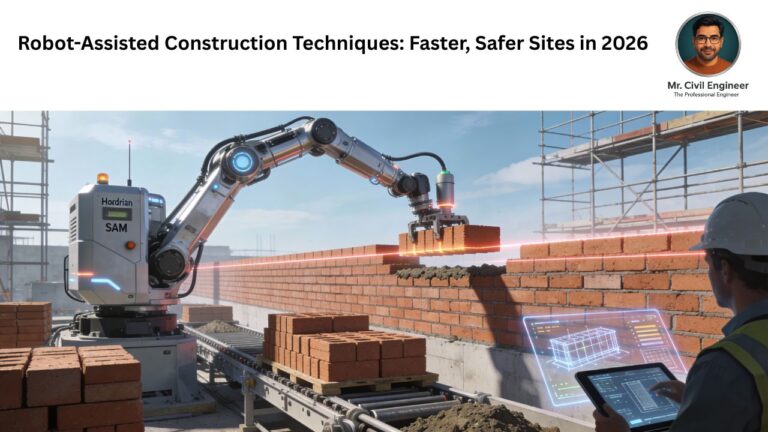

- Robot-Assisted Construction Techniques: Faster, Safer Sites in 2026

- Civil Engineering Trends in Smart Cities: India 2026 Guide