Concrete has supported civilization’s grandest structures—from the Roman aqueducts to today’s towering skyscrapers. But as demands rise for sustainability, durability, and smart infrastructure, traditional concrete evolves rapidly. The latest advancements in concrete technology are pushing boundaries, offering stronger, greener, and longer-lasting materials that

Mivan Technology in Construction – A Complete Guide

Imagine finishing a 20-floor apartment block in half the time of traditional methods, with smooth walls needing no plaster and earthquake-ready strength. That’s the promise of Mivan technology, revolutionizing sites across India from Mumbai high-rises to PMAY housing.

Developed by Malaysia’s Mivan Company Ltd., this aluminum formwork system casts entire walls, slabs, beams, and columns in one pour—creating monolithic structures faster and stronger. If you’re tired of labor-intensive brickwork delays, this guide breaks down everything from components to real costs.

What is Mivan Technology?

Mivan technology replaces plywood or steel formwork with lightweight, reusable aluminum panels. Unlike conventional step-by-step bricklaying and plastering, Mivan pours high-grade concrete into pre-assembled forms for seamless, uniform elements.

Key traits:

- Monolithic casting: Walls and slabs in single operation—no joints, less leakage.

- High reusability: Panels last 200–250 cycles.

- Precision: Ensures dimensional accuracy, ideal for repetitive mass housing.

Popular in Gulf countries and now scaling in India for urban boom projects.

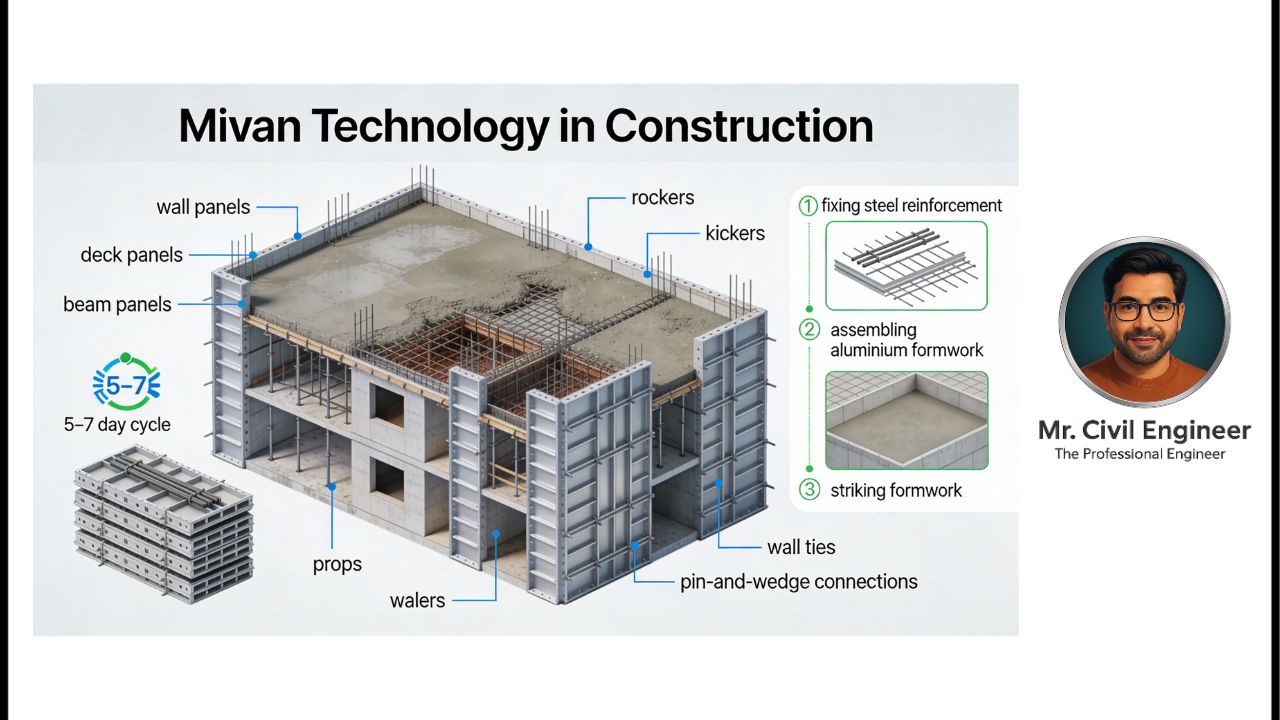

Key Components of Mivan Formwork

Mivan’s modular “Lego-like” panels snap together quickly:

- Wall panels: Vertical forms (sizes like 2000x600mm, 5mm thick aluminum alloy).

- Deck/ soffit panels: Horizontal for slabs.

- Beam panels: For beams/supports.

- Props and kickers: Stability during pour (load capacity 7–8 tonnes/sq.m).

- Pins, wedges, wall ties: Secure connections.

Weighing 18–24 kg/sq.m, unskilled labor can handle assembly—cutting skilled needs by 30–40%.

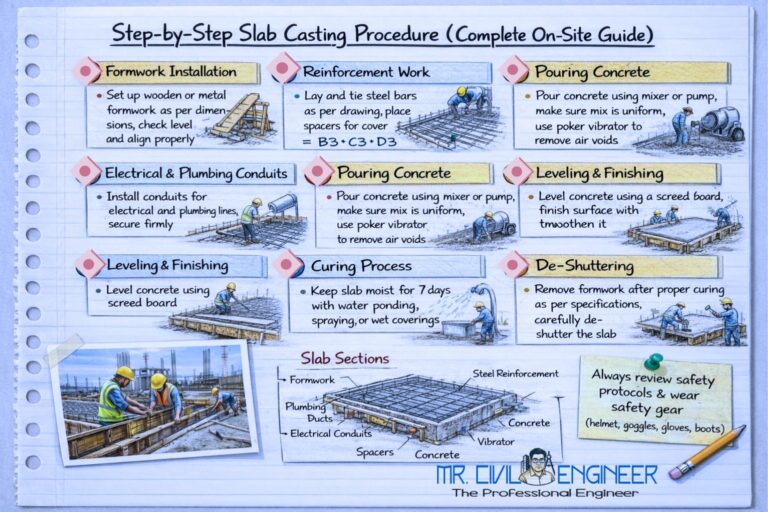

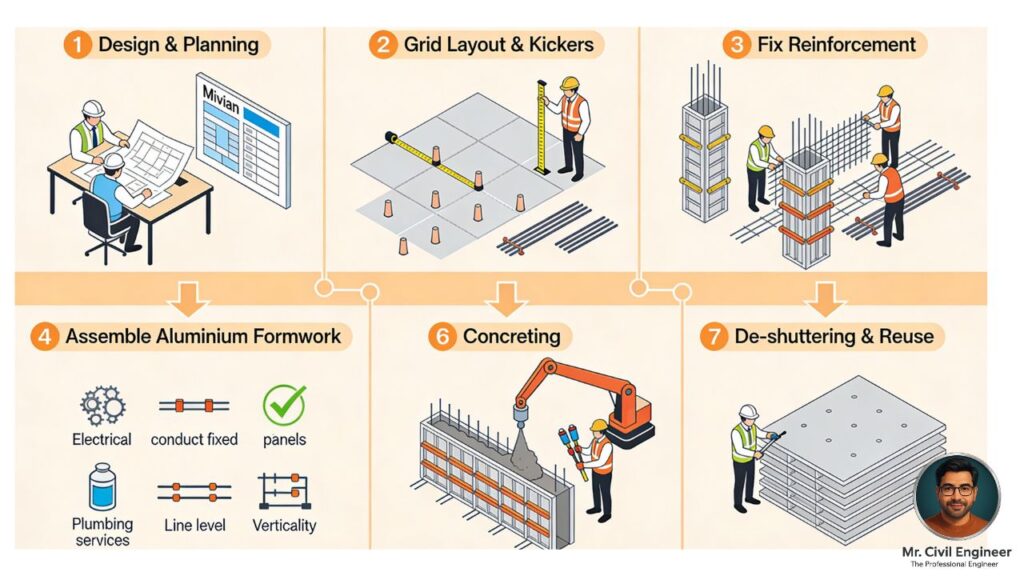

Step-by-Step Mivan Construction Process

Mivan shines in its tight 4-day floor cycle:

Day 1: Vertical assembly

- Erect wall reinforcement.

- Fix one-side wall panels + kickers.

Day 2: Complete verticals + horizontals

- Second-side walls, props, slab panels.

- Check levels, MEP openings.

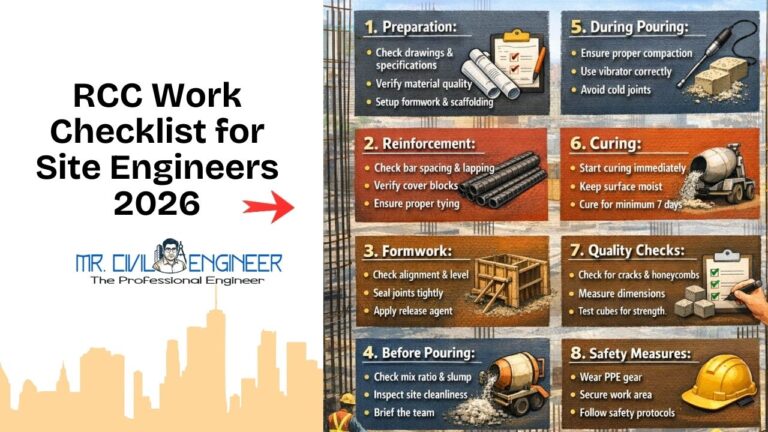

Day 3: Rebar + pour

- Place slab/wall rebar.

- Pour concrete (M25+ grade), vibrate for compaction.

Day 4: Deshuttering

- Remove verticals after 24 hrs (2 N/mm² strength).

- Slabs after 36 hrs (10 N/mm²); reuse immediately.

Repeat for next floor—achieving 6–7 days/floor overall.

Advantages of Mivan Technology

Why switch? Real benefits stack up:

- Lightning speed: 25–50% faster than conventional (e.g., G+26 building: 352 vs 668 days).

- Superior finish: Smooth surfaces skip plastering, saving 10–15% on labor/materials.

- Seismic/durability boost: Monolithic shear walls resist quakes better.

- Efficiency: Fewer workers (30% less), minimal wastage, more carpet area.

- Low maintenance: Fewer joints = less leakage/cracks long-term.

Perfect for PMAY’s mass housing targets.

Disadvantages and Challenges

Not flawless:

- High upfront cost: ₹8,000–₹16,000/sq.m initial formwork (20–25% of project vs 10–15% traditional).

- Inflexible: Design changes post-assembly tough; suits uniform layouts.

- Shrinkage cracks: Heat of hydration in thick pours—mitigate with fly ash, sealing strips.

- Small components: Post-construction services (plumbing) trickier.

Best for 10+ floors, repetitive designs—not custom villas.

Cost Comparison: Mivan vs Traditional Formwork

Data from G+26 studies:

| Aspect | Traditional | Mivan | Difference |

|---|---|---|---|

| Cost/sq.ft | ₹392 (baseline) | ₹415–₹525 | +5–33% upfront, savings via speed |

| Time/floor | 25–30 days | 4–7 days | 50% faster |

| Total project (G+26) | ₹97.44 Cr (668 days) | ₹97.57 Cr (352 days) | +0.13% cost, -47% time |

Breakeven at scale: High-rises recover via quicker sales/penalties avoided.

Real-World Applications in India

- PMAY housing: Speeds “Housing for All” with uniform flats.

- Gurugram/Mumbai towers: Urban high-rises favor Mivan for deadlines.

- Examples: Godrej PMAY projects, NHAI-linked urban schemes—delivering quality at pace.

Over 100 Indian projects by 2025, growing 30% yearly.

Tips for Successful Mivan Implementation

- Uniform design: Standard panels/elevations maximize reuse.

- Expert training: 1–2 days for crews; hire certified suppliers.

- Crack prevention: PPC cement, proper curing, expansion joints.

- Vendor check: Panels from IS-marked aluminum (6061 T6 grade).

Start with pilot floors to iron out kinks.

FAQs

What is Mivan formwork cycle time?

4 days: Day 1–2 assembly, Day 3 pour, Day 4 deshutter verticals.

Is Mivan cheaper than conventional?

Upfront higher (20–25%), but 50% time savings offset for large projects.

Suitable for small houses?

No—best for 4+ floors, repetitive mass housing.

How to prevent Mivan cracks?

Fly ash mixes, sealing strips, controlled curing.

Conclusion

Mivan technology flips construction timelines, delivering durable, plaster-free structures at unmatched speed—tailor-made for India’s housing crunch. While initial costs and rigidity pose hurdles, its ROI shines in high-volume work like PMAY towers.

Evaluate your project’s scale: if uniformity and pace matter, Mivan’s your edge. Consult suppliers early and watch delays vanish.

Read This Also

Latest Building Materials in Construction (2026 Update)

How to Estimate Brickwork and Rate Analysis with Example

Artificial Intelligence in Civil Engineering: How Smart Infrastructure is Being Built

Advanced Materials for Civil Engineering: Trends & Applications