A small river bridge in rural India gets delayed by floods because the team skipped proper hydrology surveys. Meanwhile, a major highway overpass nearby finishes ahead of schedule using precast girders and incremental launching. The difference? Smart planning and technique selection from day one.

Bridge construction techniques blend engineering precision with site realities. This guide covers the full process—from surveys to opening—highlighting methods like cast-in-situ, precast segmental, and advanced launching suited for Indian road/rail projects.

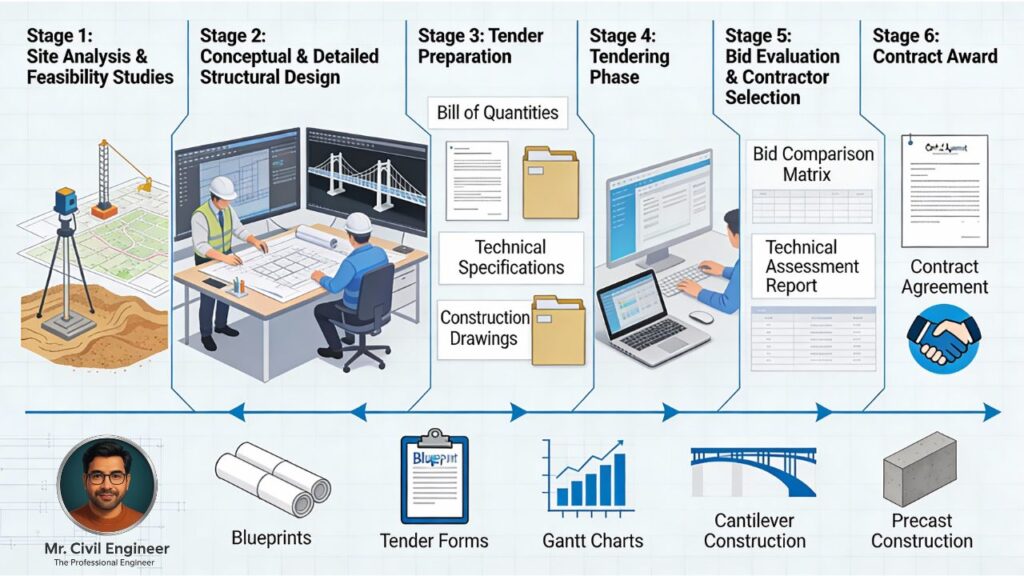

Planning and Feasibility Studies

Every bridge starts with groundwork.

- Site selection: Analyze topo sheets, traffic needs, and obstacles (river width, soil). Download surveys, mark alignment, get agency nod.

- Geotechnical surveys: Boreholes for soil strata; hydrology for HFL (high flood level), scour depth.

- Feasibility report: Economic viability, environmental impact (forest/wildlife clearance if needed).

For a typical 100m span road bridge, this phase takes 2–4 months.

Design and Tendering

Once site is fixed:

- Type selection: PSC girders for short-medium spans (20–50m); balanced cantilever or cable-stayed for 100m+.

- Detailed design: IRC 6 loading, seismic/wind per IS codes; drawings for foundation, piers, deck.

- Tender docs: BOQ, specs, timelines. Award to L1 or technically qualified bidder.

Digital tools like BIM now speed up clash detection.

Foundation and Substructure Construction

The base handles all loads.

Foundations

- Open/raft for good soil; piles (bored cast-in-situ) for weak strata.

- Well/sinking for rivers: Steel cylinders sunk by dredging, filled with concrete.

Substructure (piers/abutments)

- Cofferdams/dewatering: Temporary enclosures to build in dry for river piers.

- Pile caps (2–3m thick), piers (RCC/PSC up to 10–20m high), pier caps for girder bearings.

A 4-pier bridge foundation might take 6–9 months in monsoon-prone areas.

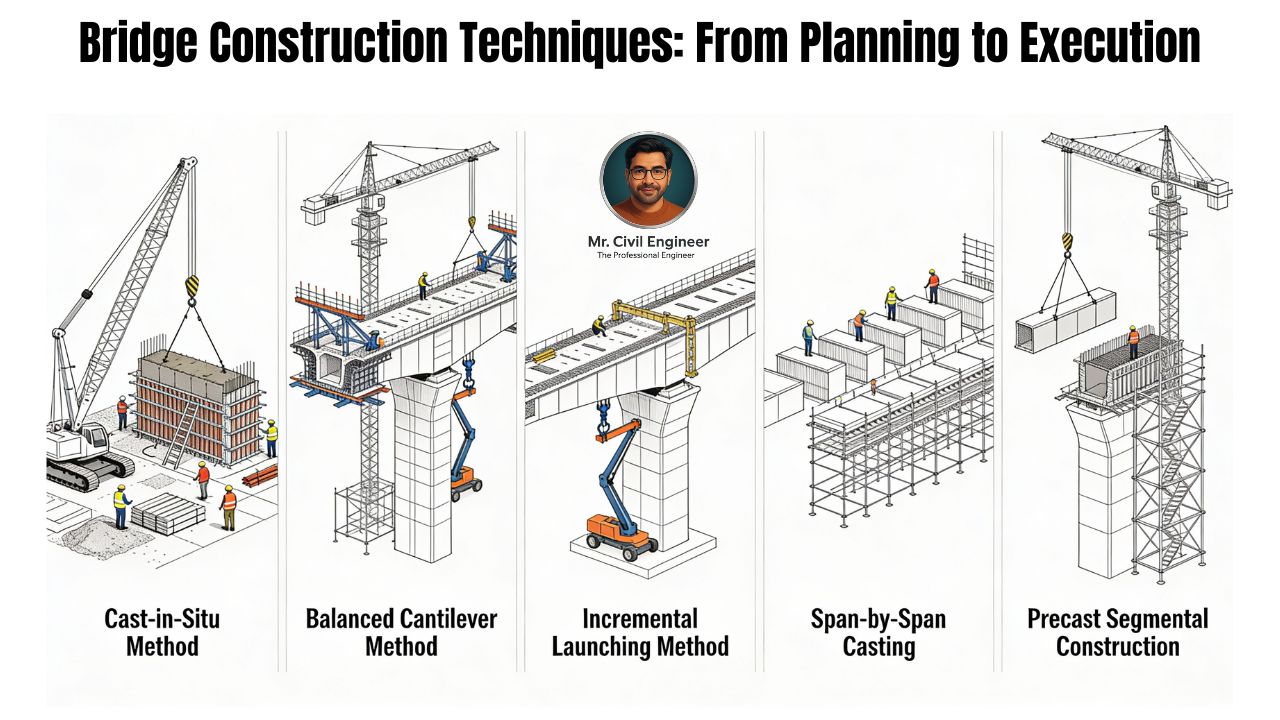

Superstructure Construction Techniques

This is where techniques shine, chosen by span, access, river flow.

Cast-in-Situ Method

- Formwork/scaffolding over piers; rebar + concrete pour for deck/beams.

- Simple for short spans but risky over water (needs full falsework).

Precast Segmental Construction

- Factory-cast segments (2–3m each) with match-cast ends.

- Erected span-by-span using cranes/launching girders; post-tensioned on-site.

- Faster, quality-controlled; ideal for uniform highway bridges.

Incremental Launching Method (ILM)

- Build deck segments behind abutment; hydraulic jacks push forward over piers (up to 250m+).

- Minimal scaffolding; great for valleys/rivers. Used on many NHAI projects.

Balanced Cantilever Method

- Cast segments alternately from piers toward mid-span; temporary stays prevent tipping.

- For 100–200m spans; common in hilly terrains.

Long-Span Specialists

- Cable-stayed: Towers + cables from pylons to deck (e.g., Bandra-Worli Sea Link segments).

- Suspension: For 500m+ (rare in India).

| Technique | Best For | Timeline Savings |

|---|---|---|

| Cast-in-situ | Short spans | Baseline |

| Precast | Medium uniform | 20–30% faster |

| ILM | River/valley | 40% less scaffolding |

| Cantilever | Long curved | Complex sites |

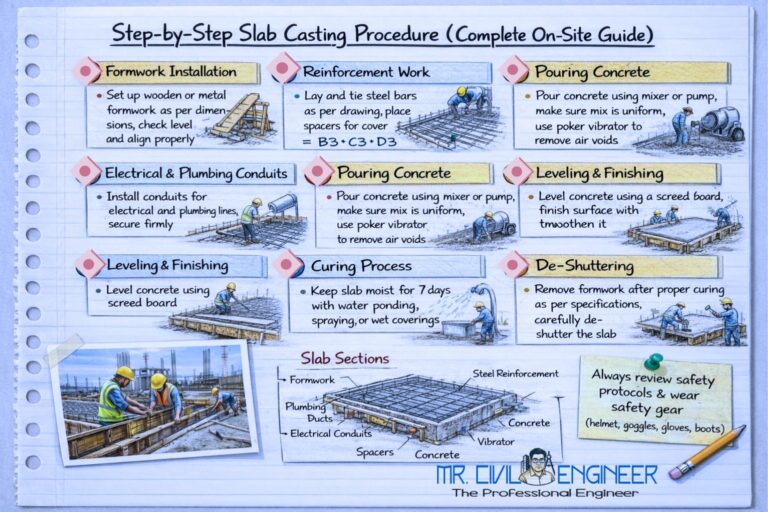

Deck Construction, Bearings, and Joints

Superstructure supports the roadway:

- Deck slab: Cast over girders (120–200mm RCC); wearing coat (bituminous concrete).

- Bearings: Elastomeric/pot PTFE for movement.

- Expansion joints: For thermal/seismic shifts.

- Approach slabs: Transition to soil.

Add railings, lighting, drainage.

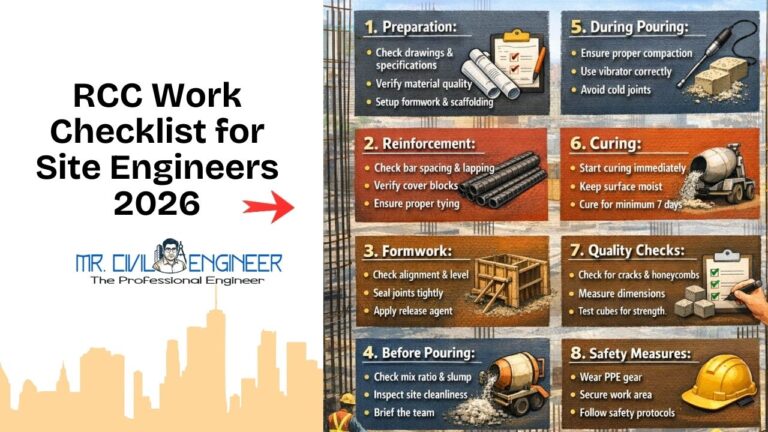

Testing, Finishing, and Commissioning

Final checks ensure safety:

- NDT: Concrete strength (rebound hammer, UPV); girder stressing verification.

- Load test: Static (sandbags/trucks) to 120% design load; dynamic for deflection.

- Finishing: Asphalt surfacing, marking, signage.

- Handover: As-built drawings, O&M manual to client.

Total timeline for 200m PSC girder bridge: 18–24 months.

Common Challenges and Solutions

- Monsoon/floods: Advance well sinking, cofferdams.

- Traffic diversion: Bailey/portable bridges during construction.

- Deep foundations: Sonic logging for pile integrity.

Modern tech: Drones for surveys, GPS for alignment.

FAQs

When to use incremental launching vs balanced cantilever?

ILM for straight alignments over obstacles (less formwork); cantilever for curved/long spans needing balance.

Foundation 6–9 months, superstructure 6–12 months, finishing 2–3 months (total 18–24 months).

What is IRC code for bridge construction?

IRC 6 (loading), IRC 21 (concrete), IRC 112 (prestressed).

Conclusion: Building Connections That Last

Bridge construction techniques—from planning surveys to ILM or precast erection—turn engineering drawings into vital lifelines. Choose methods matching your site’s span, soil, and budget, and always prioritize IRC compliance and safety.

Next time you cross a new bridge, appreciate the precise execution behind it. For infra pros, mastering these steps opens doors to NHAI/PWD tenders.