Are you planning to build a house or manage a construction project and already worried about the budget? You’re not alone. With rising prices of cement, steel, and labor, construction costs seem to climb every year.

Many people believe that the only way to reduce construction cost is to compromise on quality. But that’s not true.

Smart construction is not about using cheap materials — it’s about using the right materials, the right design, and the right planning. In this guide, we’ll explore practical and proven ways to reduce construction cost without quality loss.

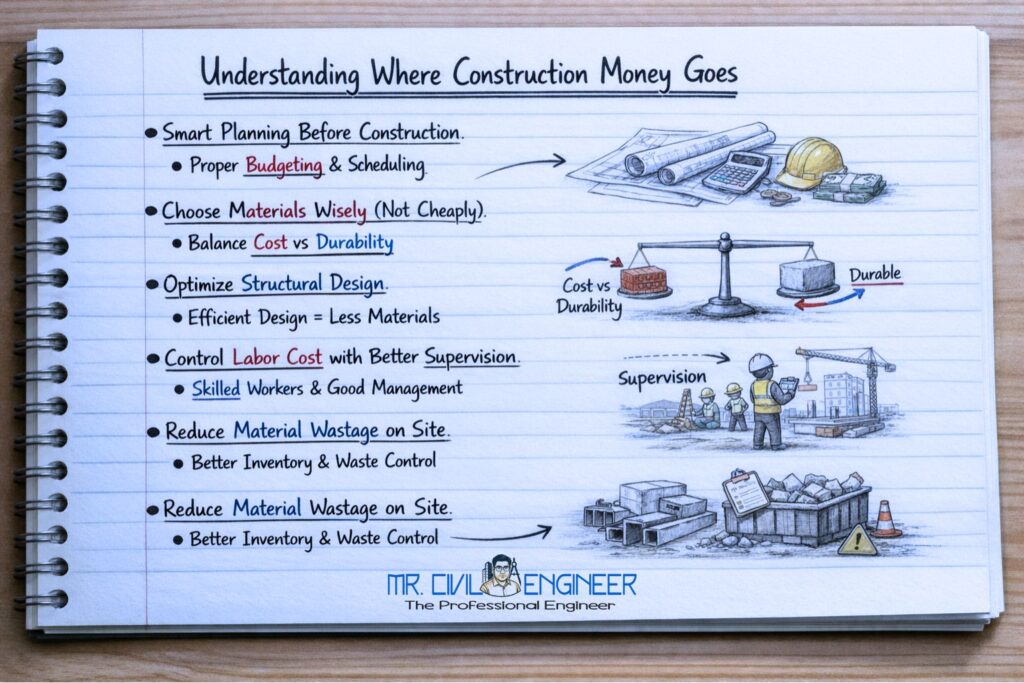

Understanding Where Construction Money Goes

Before learning how to save money, you must know where money is spent.

Major cost components in construction:

- Materials (cement, steel, bricks, sand, aggregate) – 55–60%

- Labor – 20–25%

- Equipment & formwork – 5–10%

- Overheads & wastage – 5–10%

Most cost overruns happen due to:

❌ Poor planning

❌ Material wastage

❌ Design changes during construction

❌ Rework due to poor workmanship

If you control these, you automatically control cost.

1. Smart Planning Before Construction

Good planning is the biggest money saver.

✔ Prepare proper drawings

Never start construction with rough sketches. Detailed drawings reduce:

- Material mismatch

- Design confusion

- On-site alterations

✔ Do accurate estimation

Prepare:

- Quantity estimation

- Material requirement list

- Labor schedule

A proper estimate helps you:

- Avoid over-ordering

- Track expenses

- Compare contractor rates

📌 Studies show that projects with proper planning save up to 10–15% in total cost compared to poorly planned projects (Source: PMI construction reports).

2. Choose Materials Wisely (Not Cheaply)

Saving money doesn’t mean buying low-grade materials.

Smart material selection means:

- Use standard grade cement and steel (avoid unnecessary high grades)

- Avoid over-specification (don’t use M40 concrete where M20 is enough)

- Prefer locally available materials to reduce transport cost

- Use alternative materials like:

- Fly ash bricks

- AAC blocks

- Manufactured sand (M-sand)

These alternatives:

✔ Meet strength standards

✔ Reduce dead load

✔ Reduce plaster thickness

✔ Save up to 8–12% in material cost

3. Optimize Structural Design

Overdesign is one of the silent budget killers.

Example:

Using heavy beams and thick slabs where lighter sections would work increases:

- Concrete volume

- Steel quantity

- Formwork area

What you should do:

- Ask for structural optimization

- Avoid unnecessary projections and curves

- Use regular grid layout for columns and beams

A simple rectangular plan is always cheaper than a complex shape.

4. Control Labor Cost with Better Supervision

Labor cost increases when:

- Workers redo work

- Material is wasted

- Time is wasted

To reduce labor cost:

✔ Hire skilled workers for critical jobs

✔ Provide clear instructions

✔ Ensure proper curing and workmanship

✔ Monitor daily progress

Rework can increase project cost by 5–7% easily. Preventing mistakes saves both money and time.

5. Reduce Material Wastage on Site

Construction wastage = money thrown away.

Common wastage sources:

- Cement damaged by moisture

- Steel rusting

- Broken bricks

- Excess concrete mix

How to reduce wastage:

- Store cement on raised platforms

- Cover sand and aggregate

- Cut steel with proper planning

- Mix concrete as per requirement

- Reuse formwork properly

A well-managed site can reduce wastage by 3–5%, which is a big saving on large projects.

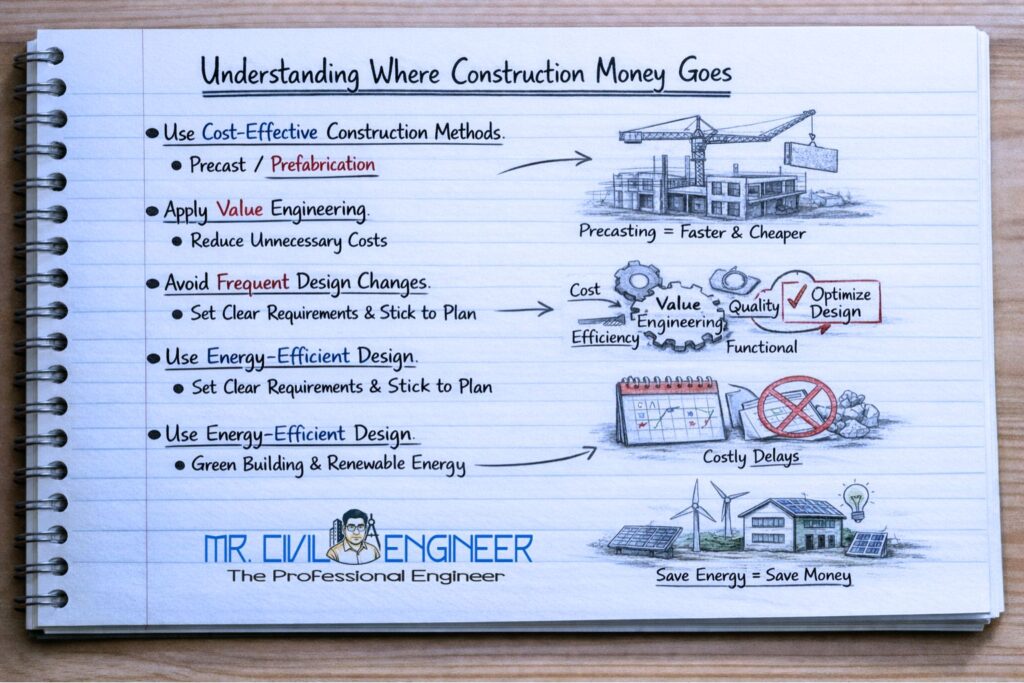

6. Use Cost-Effective Construction Methods

Modern construction methods help reduce time and cost.

Examples:

- Modular formwork

- Prefabricated elements

- Ready-mix concrete

- Mechanized bricklaying

These methods:

✔ Improve speed

✔ Reduce labor dependency

✔ Improve quality control

✔ Reduce overall project cost

Shorter project duration = lower overhead cost.

7. Apply Value Engineering

Value engineering means:

Achieving the same function at lower cost without reducing quality.

Example:

- Using hollow blocks instead of solid bricks

- Using flat slab where suitable

- Using filler slab for roofs

- Using standard door/window sizes

Value engineering focuses on:

✔ Function

✔ Strength

✔ Durability

✔ Economy

Not luxury.

8. Avoid Frequent Design Changes

Changing design during construction is expensive.

Every change leads to:

- Demolition

- Rework

- Extra material

- Delay

Tip:

Finalize:

- Layout

- Elevation

- Plumbing & electrical plans

before starting work.

Late decisions = high cost.

9. Use Energy-Efficient Design

Energy-efficient buildings save money in long term.

Use:

- Proper natural ventilation

- Daylighting

- Thermal insulation

- Reflective roof coating

This reduces:

- Cooling cost

- Lighting cost

- Maintenance cost

Initial design choices can reduce lifetime cost by 20–30%.

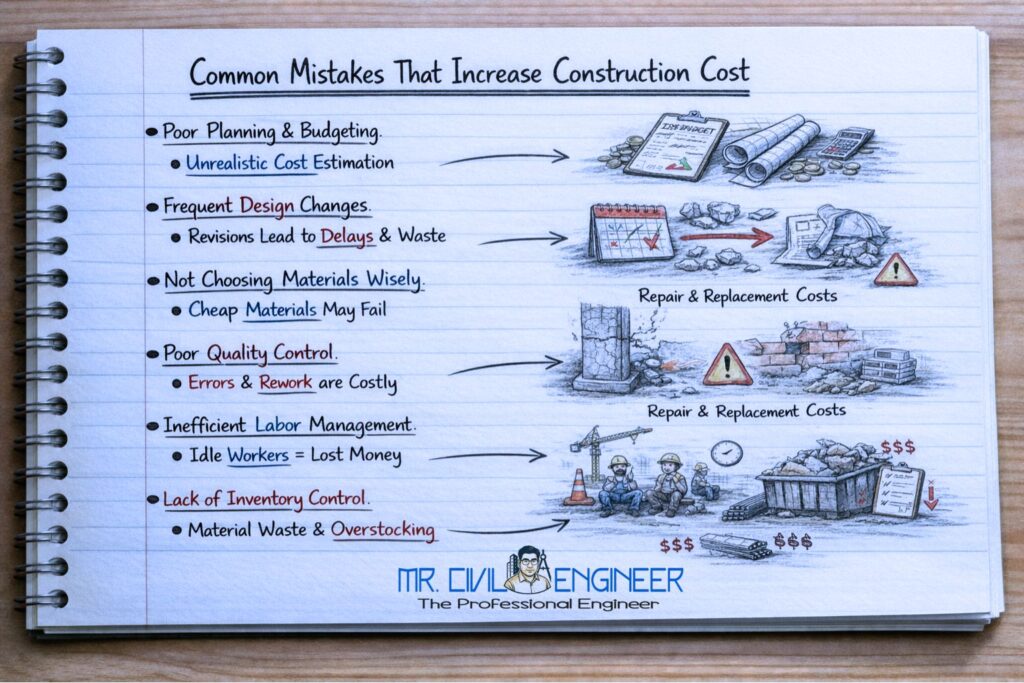

🔹 Common Mistakes That Increase Construction Cost

❌ Buying cheapest material

❌ Starting without estimate

❌ No site supervision

❌ Ignoring drawings

❌ Last-minute changes

❌ Poor curing

❌ Overuse of cement

Cheap work today = expensive repairs tomorrow.

FAQs

Q1. Can I reduce construction cost without affecting strength?

Yes. By optimizing design, reducing wastage, and selecting correct materials, you can reduce cost without reducing structural safety.

Q2. Which saves more money: material or labor control?

Both are important, but material control gives bigger savings because it forms the largest part of total cost.

Q3. Is low-cost construction durable?

Low-cost does not mean low quality. Smart low-cost construction can be just as durable as expensive construction if standards are followed.

Q4. Should I hire an engineer to reduce cost?

Yes. A qualified engineer helps in:

- Structural optimization

- Material planning

- Cost estimation

which saves more money than their fee.

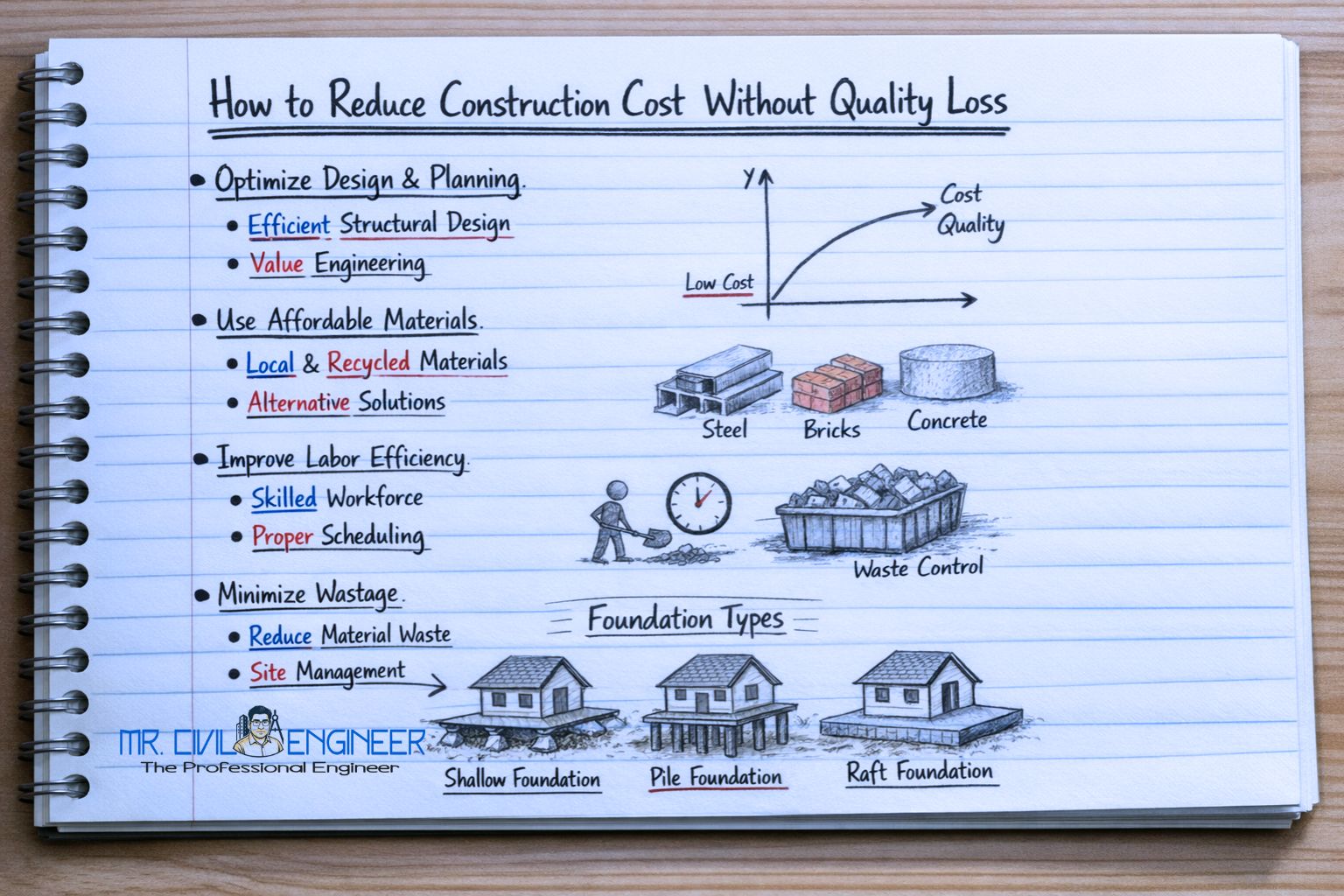

🔹 Conclusion

Reducing construction cost does not mean reducing quality. It means reducing waste, poor planning, and unnecessary expenses.

By focusing on:

- Proper planning

- Smart material selection

- Structural optimization

- Skilled workmanship

- Waste control

- Value engineering

You can build a strong, safe, and durable structure within your budget.

In construction, the smartest savings come not from cheaper materials — but from better decisions.

Latest Articles

- Curing Methods in Concrete: Types, Importance & Best Practices

- Safety Measures on Construction Site: What Every Engineer Must Know

- Construction Joints – Types & Location (Complete RCC Guide)

- Concrete Pouring Checklist for Hot Weather (Site-Practical Guide)

- Shuttering Types & Removal Time (Complete RCC Site Guide)

[…] How to Reduce Construction Cost Without Quality Loss […]

[…] How to Reduce Construction Cost Without Quality Loss […]

[…] How to Reduce Construction Cost Without Quality Loss […]

[…] How to Reduce Construction Cost Without Quality Loss […]