Have you ever seen a freshly cast concrete slab develop cracks within days—even when the mix design was perfect?

This is one of the most common site problems, and the culprit is often improper curing.

Concrete does not gain strength just by hardening. It needs continuous moisture and temperature control to develop its full potential. That process is called curing, and it is one of the most critical yet neglected stages of concrete construction.

This guide explains curing methods in concrete in a simple, practical, and site-friendly manner.

What Is Curing in Concrete?

Curing is the process of maintaining adequate moisture, temperature, and time in concrete after placement so that cement hydration can continue.

In simple terms:

Curing helps concrete gain strength, durability, and resistance to cracking.

Without proper curing, cement particles do not hydrate fully, resulting in weak and brittle concrete.

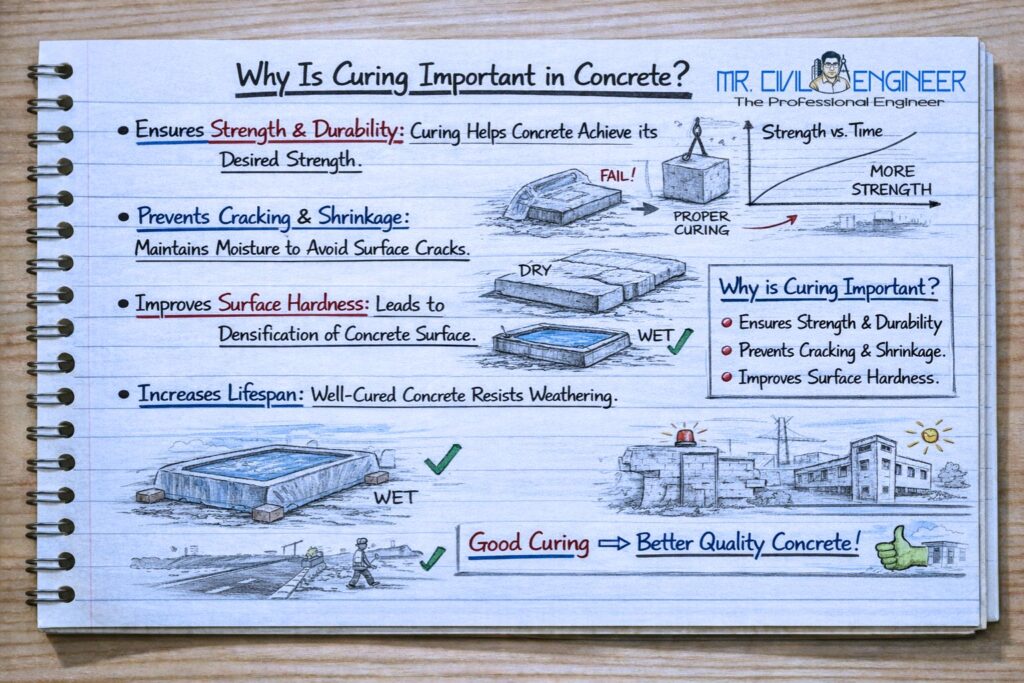

Why Is Curing Important in Concrete?

1. Strength Development

Concrete gains nearly 70% of its strength in the first 7 days—only if curing is done properly.

2. Prevents Cracks

Rapid moisture loss causes plastic shrinkage and surface cracks.

3. Improves Durability

Well-cured concrete resists:

- Weathering

- Chemical attack

- Abrasion

4. Ensures Proper Cement Hydration

Curing allows cement to react with water completely, forming a strong internal structure.

Factors Affecting Curing of Concrete

- Temperature: Hot weather increases evaporation

- Humidity: Low humidity dries concrete faster

- Wind speed: Accelerates moisture loss

- Type of cement: OPC needs longer curing than PPC

- Concrete surface area: Slabs need more attention

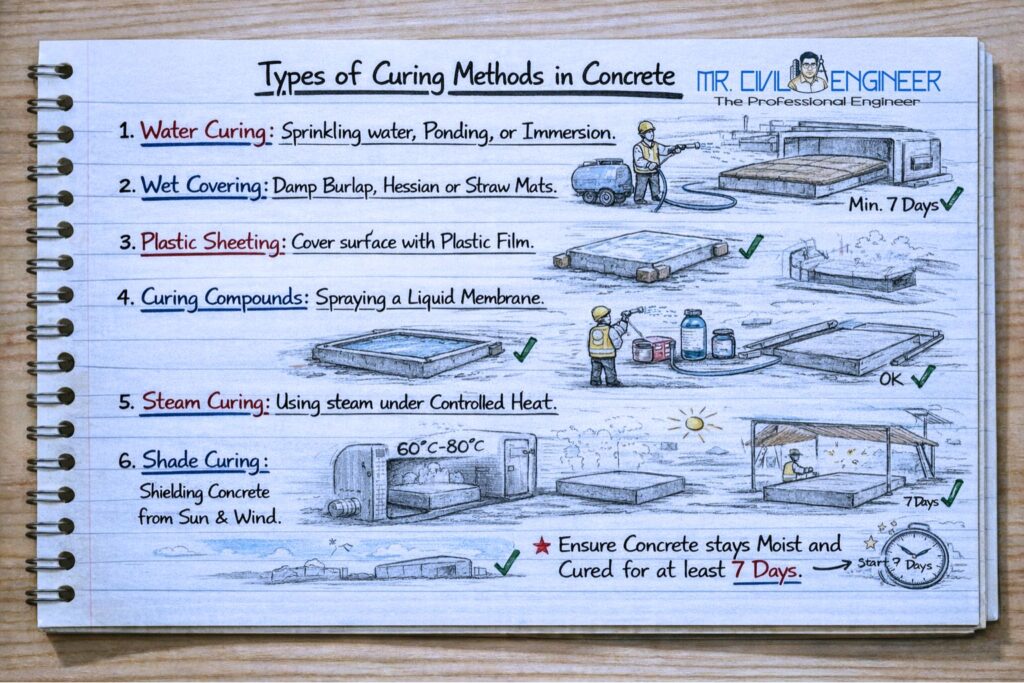

Types of Curing Methods in Concrete

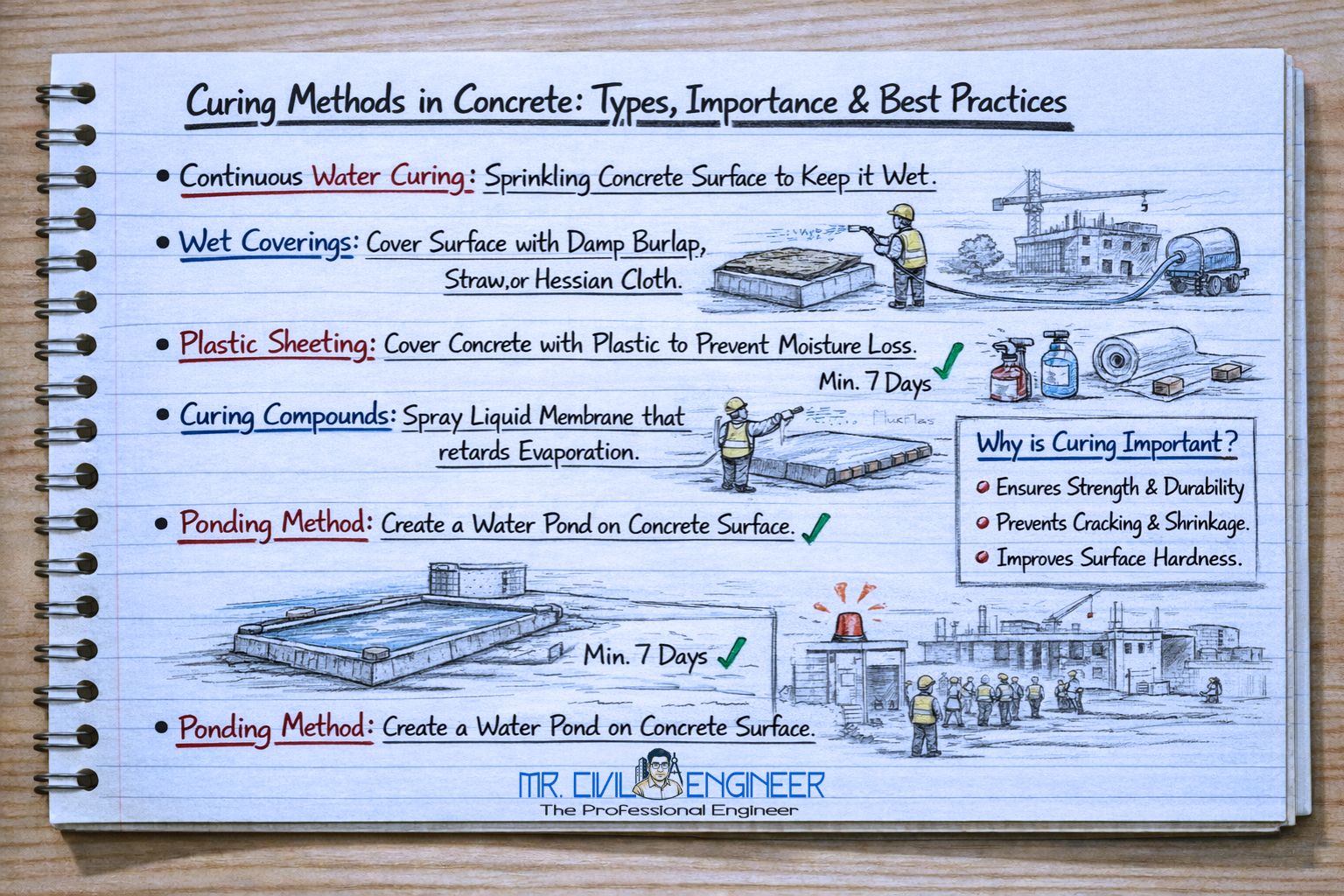

1. Water Curing (Most Common Method)

Water curing keeps concrete continuously wet.

Methods include:

- Ponding (for slabs)

- Sprinkling

- Wet gunny bags

Advantages

- Most effective and economical

- Ensures maximum strength

Disadvantages

- Requires continuous water supply

- Labor-intensive

Best for: Slabs, beams, columns on site

2. Membrane Curing

A thin impermeable layer is applied to prevent moisture loss.

Examples

- Plastic sheets

- Bituminous membranes

Advantages

- Saves water

- Suitable for remote sites

Disadvantages

- Does not add moisture

- Requires proper application

3. Steam Curing

Concrete is exposed to steam under controlled conditions.

Advantages

- Rapid strength gain

- Ideal for precast elements

Disadvantages

- High cost

- Not suitable for normal site work

4. Chemical (Curing Compounds)

Liquid compounds sprayed on concrete surface.

Advantages

- Easy to apply

- Reduces labor

Disadvantages

- Costly

- Not suitable for surfaces requiring plaster or finishes later

5. Natural Curing

Relies on ambient moisture and temperature.

Note:

This method is not reliable and should not be used for RCC structures.

Recommended Curing Duration

- OPC Cement: Minimum 7–10 days

- PPC / PSC Cement: Minimum 10–14 days

- Hot weather: Increase curing duration

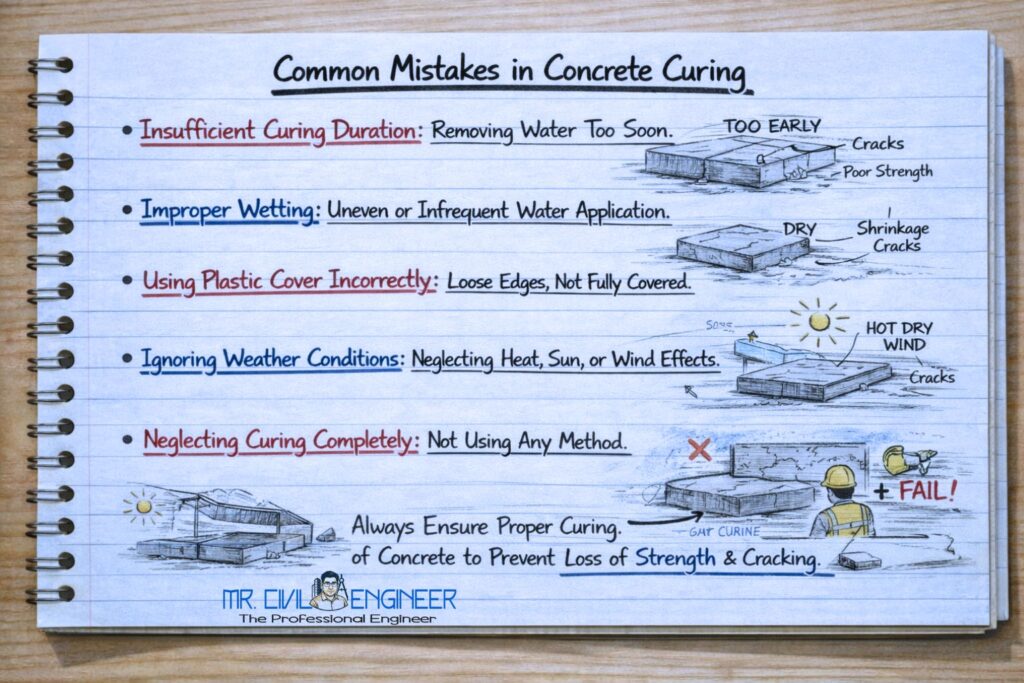

Common Mistakes in Concrete Curing

- Starting curing too late

- Stopping curing early

- Allowing surface to dry

- Ignoring curing in hot weather

Best Practices for Site Engineers

- Start curing within 6–12 hours after casting

- Keep concrete surface continuously wet

- Protect concrete from direct sunlight

- Use curing compounds where water is scarce

Frequently Asked Questions (FAQs)

Q1. Is curing really necessary if concrete looks hard?

Yes. Hardening is not equal to strength development.

Q2. What happens if curing is not done properly?

Low strength, cracks, dusting, and reduced durability.

Q3. Which curing method is best?

Water curing is the best and most effective for site work.

Conclusion

Curing is not an optional step—it is the foundation of concrete strength and durability. Even the best mix design can fail without proper curing.

If you want crack-free, strong, and durable RCC structures, never compromise on curing.

Good concrete is made by design.

Strong concrete is made by curing.

Latest Articles

- Safety Measures on Construction Site: What Every Engineer Must Know

- Construction Joints – Types & Location (Complete RCC Guide)

- Concrete Pouring Checklist for Hot Weather (Site-Practical Guide)

- Shuttering Types & Removal Time (Complete RCC Site Guide)

- Step-by-Step Slab Casting Procedure (Complete On-Site Guide)

[…] Curing Methods in Concrete: Types, Importance & Best Practices […]

[…] Curing Methods in Concrete: Types, Importance & Best Practices […]